Product Introduction

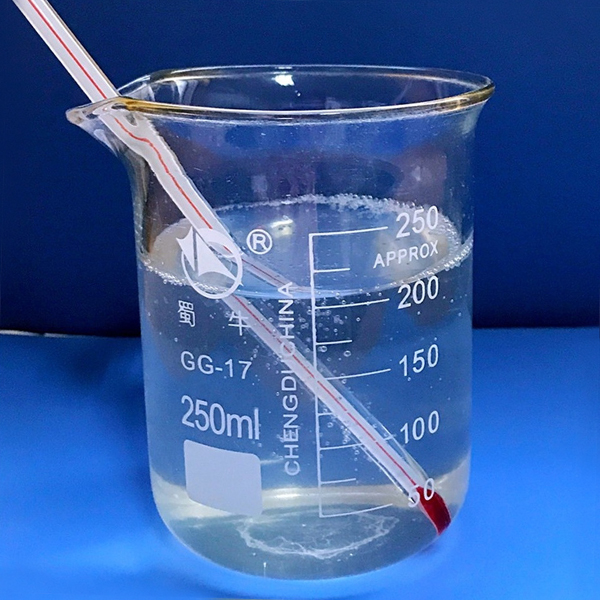

Hydroxy propyl methyl cellulose (HPMC) is odorless, tasteless,non-toxic cellulose ethers produce from natural high molecula and protective colloid properties of surface activity and maintain moisture function properties ect.cellulose through series of chemical processing and achieved.It is white powder with good water solubility. It has thickening, adhesion ,dispersing, emulsifying, film, suspended, adsorption, gel.

In the course of construction,HPMC is used for wall putty, tile adhesive, cement mortar, dry mix mortar, wall plaster, skim coat, mortar, concrete admixtures, cement, gypsum plaster, joints fillers, crack filler, etc.

Product Parameters

|

Product name

|

Hydroxy propyl methyl cellulose (HPMC)

|

|

Content of methoxyl

|

24.0 - 30.0

|

|

Content of hydroxy propyl

|

9.0 - 12.0

|

|

Temperature of gelation

|

63℃ - 75 ℃

|

|

Moisture

|

≦5%

|

|

Ash

|

≦5%

|

|

PH value

|

7 - 8

|

|

Appearance

|

white powder

|

|

Fitness

|

80-100 mesh

|

|

Viscosity

|

4,000 to 200,000 it can be customized

|

|

HPMC increased with methoxy content reduce, the gel point water solubility and surface activity also declind, depends on customer's situation.

|

|

|

specification

|

viscosity range

|

specification

|

viscosity range

|

|

400

|

350 -500

|

30000

|

24000-36000

|

|

1500

|

1300 -1800

|

35000

|

28000-42000

|

|

3500

|

3000-4500

|

40000

|

32000-48000

|

|

5000

|

4000-6000

|

50000

|

40000-60000

|

|

6000

|

5500-7000

|

60000

|

56000-65000

|

|

9000

|

8000-10000

|

80000

|

75000-85000

|

|

10000

|

9000-11000

|

100000

|

85000-130000

|

|

18000

|

16000-20000

|

150000

|

130000-180000

|

|

20000

|

19000-22000

|

200000

|

>180000

|

Supply Ability

Supply Ability: 50 Ton/Tons per Day

Packaging & Delivery

Packaging Details: 25 kg per bag,500kg or 600kg per pallet

Port: Tianjin ,shanghai ,qingdao Port

Lead Time:

| Quantity(Kilograms) | 1 - 1 | 2 - 20 | 21 - 50 | >50 |

| Est. Time(days) | 3 | 6 | 10 | To be negotiated |

Product Details Show

HPMC Main Function

1.Enhanced water retention-improved water retention can protect cement and plaster against poor solidification and cracking due to speedy drying and inefficient mixing with water.

2.Workability-mortar plasticizing quality can be improved,which in return will improve the workability of painting and working efficiency.

3.Binding-Dur to increased plasticizing quality,mortar can be a better binder.

4.Slipping resistance-Due to the thickening action of cellulose ether,the slipping phenomena of mortar from substance to bound can be prevented more efficiently.

Why Choose Us

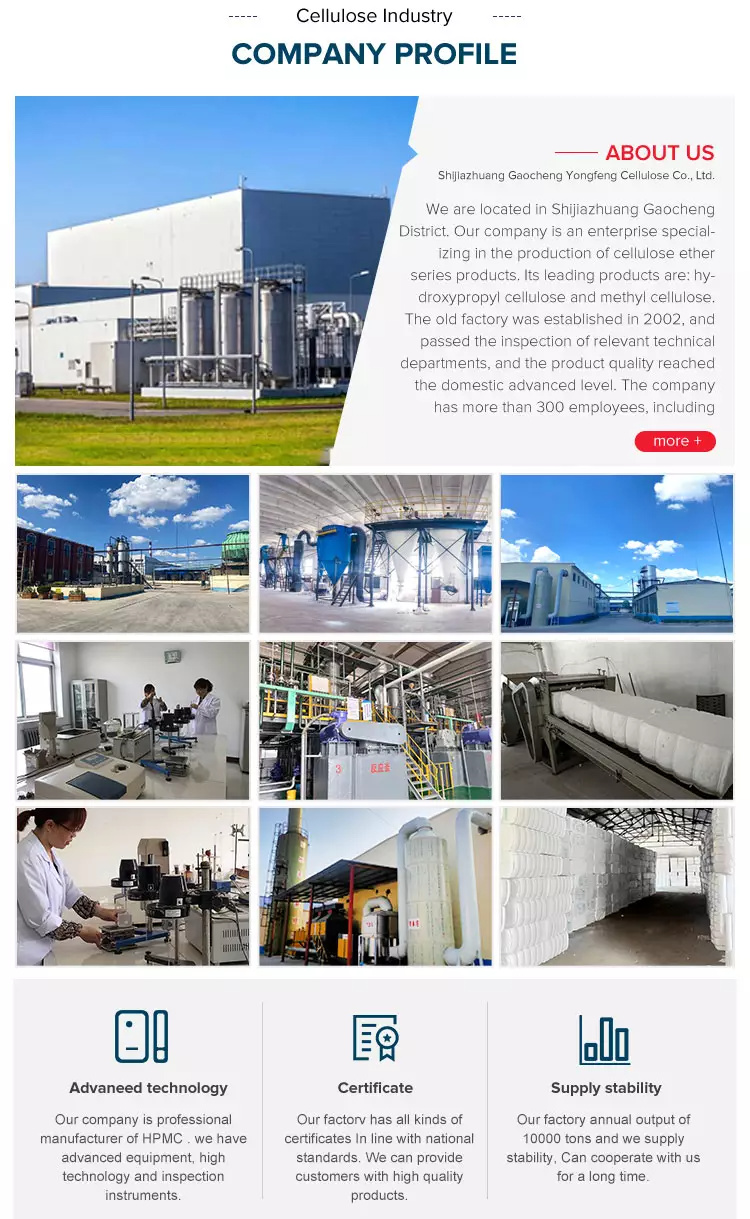

About us

1. Our facotry have found 10 years,we are the professional manufacture HPMC.

Equipment & technology

2, We have advanced equipments, high technology and standard inspection instruments, the test methods confirm to international standards.

3, Our factory annual output of 10000 tons and we supply stability

Packing & Delivery

Packing: 20/25kg plastic bag inner with PE pag. big bag or opther special packing are possible on request

Delivery: by sea , air, or other ways . 12tons per 20FCL with pallet or 14 tons without pallet.

Our Company

FAQ

1. Are you manufacturer or trading company?

We are manufacturer and we have import and export right.

2. How can you promise your quality is good?

(1) Free sample provide for test.

(2) Before delivery , each batch will be tested strictly and retained sample will be kept in our stock to trace the variations of product quality.

3. What is your payment?

L/C at sight or T/T 30% in advance, 70% balance againest the copy of B/L.

4. Are you supply OEM?

we could offer OEM service according to customers requirement.

5. About the storage?

Stored in cool and dry place, avoid humidity and direct sunlight.

6. Can you produce according to the sample?

Yes , we can produce according to the sample.

7. What is your loading port?

Tianjin port.