Exploring HPMC Mortar A Key Material in Modern Construction

In the ever-evolving world of construction materials, Hydroxypropyl Methylcellulose (HPMC) mortar has emerged as a significant player, gaining popularity among architects, builders, and construction engineers. Recognized for its versatility and performance, HPMC mortar is redefining standards in masonry applications, offering numerous benefits that cater to the modern construction landscape.

What is HPMC?

HPMC is a cellulose derivative that is widely used in various industrial applications, especially in the construction sector. It is a white, odorless powder that is soluble in cold water, forming a viscous and transparent solution. This unique property makes HPMC an essential additive in producing mortar, particularly when it comes to enhancing the performance characteristics of cement-based products.

Properties of HPMC Mortar

The incorporation of HPMC in mortar compositions imparts several functional properties, which set it apart from traditional mortar types.

1. Improved Workability HPMC acts as a thickening agent, offering a creamy consistency that enhances the workability of the mortar. This feature is particularly beneficial for plastering and rendering applications, as it allows for easier handling and application, reducing fatigue for workers on site.

2. Increased Adhesion When used in tile adhesives and thin-layer mortars, HPMC significantly improves the adhesion between surfaces. This quality ensures that tiles are securely bound to the substrate, minimizing the risk of delamination or failure, especially in environments subjected to thermal expansion and contraction.

3. Water Retention One of the standout properties of HPMC mortar is its exceptional water retention capability. This feature allows for a prolonged open time, giving workers ample time to adjust and position tiles or other materials without the risk of premature drying. In turn, this leads to stronger adhesion and better overall durability of the finished product.

4. Resistance to Cracking Mortars that incorporate HPMC exhibit enhanced flexibility, making them more resistant to cracking caused by temperature fluctuations or substrate movements. This property is vital in areas prone to seismic activity or extreme weather conditions.

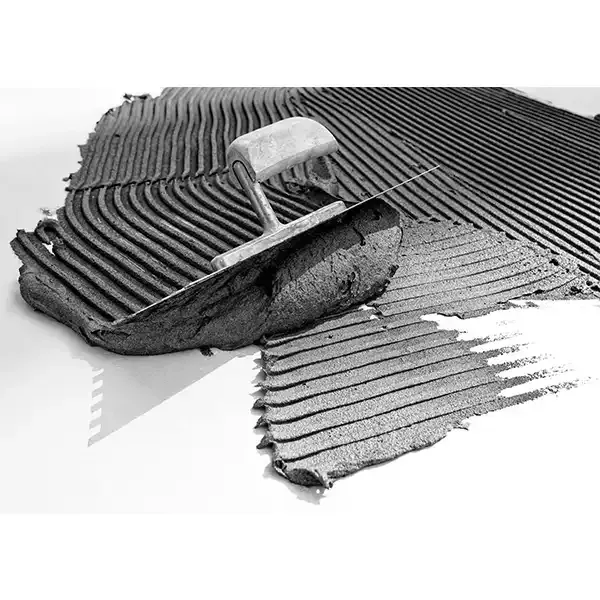

hpmc mortar

5. Compatibility HPMC mortar is compatible with various other components and additives, enabling formulators to optimize performance for specific applications. Whether it's for enhancing water resistance or controlling setting times, HPMC can be a versatile ingredient in creating tailored mortar solutions.

Applications of HPMC Mortar

The applications of HPMC mortar are extensive, ranging from residential to commercial constructions. Some of the most common uses include

- Tile Setting HPMC mortar is widely used as a tile adhesive in both interior and exterior settings. Its superior adhesion properties make it ideal for securing ceramic, porcelain, and natural stone tiles, even in moist environments.

- Plastering and Rendering The improved workability and water retention capacity of HPMC mortar make it an excellent choice for plastering walls and ceilings. It allows for a smooth finish and prevents cracking, ensuring longevity.

- Repair Mortars In repair applications, HPMC mortar can be modified to enhance its bonding capacity and flexibility. This makes it suitable for patching cracks or repairing masonry walls without compromising strength.

- Facade Systems For modern facade systems, HPMC mortar provides the necessary adhesion and flexibility to handle diverse weather conditions, ensuring that the aesthetic appeal of buildings is maintained while protecting structural integrity.

Conclusion

As the construction industry continues to push towards higher standards of performance and sustainability, HPMC mortar stands out as a superior choice among various material options. Its unique properties not only enhance the efficiency and durability of construction projects but also contribute to a more reliable and sustainable building practice.

With ongoing research and development, the future of HPMC mortar looks promising, as it adapts to meet the changing needs of construction professionals globally. Whether used in home renovations or major infrastructure projects, HPMC mortar is poised to play an essential role in shaping the future of modern construction.

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025

-

Construction Adhesive StrengthNewsAug.29,2025