Understanding Additive Powder Revolutionizing Modern Manufacturing

Additive powders have revolutionized the manufacturing landscape over the past few decades, offering unparalleled advantages in various industries, particularly in the realm of additive manufacturing (AM), commonly known as 3D printing. As this technology continues to evolve, understanding the role and composition of additive powders becomes essential for both manufacturers and consumers.

At its core, additive powder refers to the fine particulate materials used in powder-based additive manufacturing processes. These powders can be metals, polymers, ceramics, or composites, each tailored for specific applications. The unique properties of these powders enable the construction of complex geometries that would be impossible to achieve using traditional subtractive manufacturing methods.

Types of Additive Powders

1. Metal Powders These are among the most commonly used powders in additive manufacturing, particularly for industries such as aerospace, automotive, and medical. Common metal powders include stainless steel, titanium, nickel alloys, and aluminum. The selection of a specific metal powder depends on factors such as strength, weight, thermal properties, and corrosion resistance.

2. Polymer Powders These powders are popular in industries requiring lightweight components and cost-effective production runs. Materials like nylon, polyamide, and thermoplastic elastomers are commonly used. Polymer powders are favored for their versatility and ease of processing through methods like Selective Laser Sintering (SLS).

3. Ceramic Powders Ceramics offer high strength and thermal resistance, making them suitable for applications in the electronics and biomedical fields. Commonly used ceramic powders include alumina and zirconia, which can withstand high temperatures and harsh environments.

4. Composite Powders The development of composite powders—where two or more materials are combined—has opened new avenues for innovation. These materials aim to harness the beneficial properties of each component to create superior products.

The Benefits of Using Additive Powders

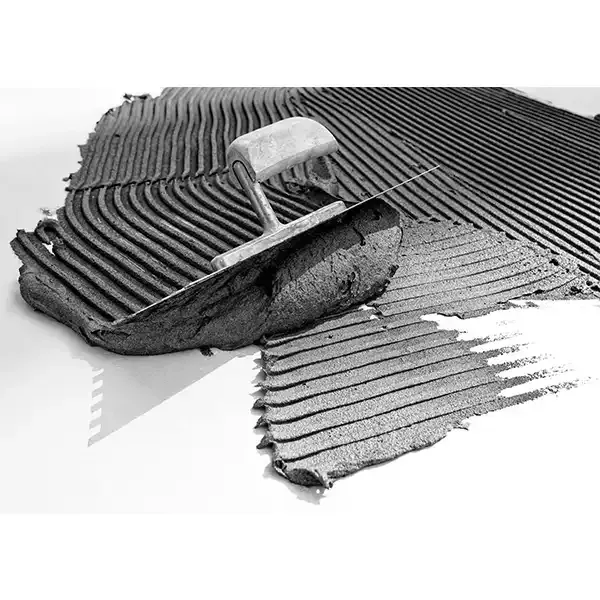

additive powder

The most significant advantage of using additive powders lies in design freedom. Manufacturers can create intricate designs, including internal features and complex structures that traditional methods cannot produce efficiently. Additionally, additive manufacturing allows for the production of parts on-demand, reducing waste and minimizing inventory costs.

Another critical benefit is customization. With the capability to easily modify designs and adapt to specific customer needs, companies can provide tailored solutions rapidly, leading to improved customer satisfaction and market competitiveness.

Moreover, additive powders enable significant reductions in weight without compromising strength, particularly in aerospace and automotive applications. This weight reduction contributes not only to improved performance but also to fuel efficiency.

Challenges and Considerations

Despite their advantages, the use of additive powders does come with challenges. The need for precise control of powder properties—such as particle size, distribution, and flowability—is paramount, as these factors can significantly impact the quality and performance of the finished parts.

Moreover, the processing parameters, including temperature and layer thickness, must be meticulously monitored to ensure optimal results. Continuous research and development aim to address these challenges, leading to better powder formulations and improved processing techniques.

Conclusion

Additive powders are at the forefront of modern manufacturing, driving innovation across various sectors. As the technology matures, we can expect even more advanced materials and processes to emerge, further expanding the possibilities of additive manufacturing. Understanding and harnessing the potential of additive powders will be crucial for manufacturers looking to stay competitive in an ever-evolving market. The future is bright, and additive powders are certainly a significant part of that future.

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025

-

Construction Adhesive StrengthNewsAug.29,2025