- Overview of essential paint chemicals and their functions

- Technical advantages of modern paint formulations

- Comparative analysis of leading manufacturers

- Customized chemical solutions for industry needs

- Real-world industrial application case studies

- Innovations in eco-friendly paint chemistry

- Future trends in paint chemical technology

(chemicals used in paints )

Understanding Essential Chemicals Used in Paints

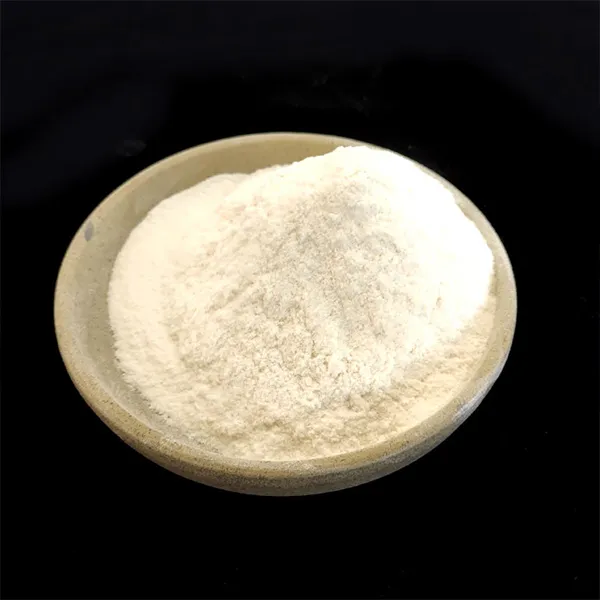

Modern paint formulations represent sophisticated chemical ecosystems where each component performs critical functions. Binders like acrylics, alkyds, and polyurethanes create durable films, constituting 25-35% of typical architectural paints. Solvents including ethylene glycol ethers and mineral spirits (representing 15-20% by volume) control viscosity during application then evaporate during curing. Pigments such as titanium dioxide (used in 80% of white paints) provide opacity and color, while extenders like calcium carbonate improve surface properties.

Specialty additives demonstrate remarkable chemical innovation: Cellulose for paints (primarily carboxymethyl cellulose and hydroxyethyl cellulose) significantly enhance rheology control. These cellulose derivatives improve sag resistance and application properties at minimal 0.2-1% concentrations. Recent industrial surveys reveal that cellulose ethers are incorporated in approximately 70% of premium water-based paints for their sustainable profile and technical advantages over synthetic alternatives.

Technical Advantages of Advanced Formulations

Contemporary chemical technologies deliver substantial performance enhancements. Water-based acrylic binders now achieve near-parity with solvent-borne systems, reducing VOC content below 50g/L while maintaining durability. Nano-engineered additives provide extraordinary capabilities: silicon dioxide nanoparticles enhance scratch resistance by 60% at just 2% loading, and photocatalytic titanium dioxide actively decomposes pollutants. Corrosion-inhibiting pigments like zinc phosphate enable 15-year industrial coating warranties even in maritime environments.

For specialized applications, cellulose derivatives offer unique solutions. Hydrophobically modified ethoxylated urethane rheology modifiers (HEUR) provide shear-thinning behavior critical for spray applications, with spray transfer efficiency improvements of 18-22%. Meanwhile, advances in cellulose stabilization mean modern paints retain consistent viscosity for over 24 months - a 40% improvement over decade-old formulations.

| Manufacturer | Core Technology | Bio-Based Content | Global Market Share | R&D Investment |

|---|---|---|---|---|

| AkzoNobel | Patent-pending EcoLac binders | 45-60% | 14% | $290M annually |

| PPG Industries | EnviroPrime crosslinkers | 30-50% | 12% | $315M annually |

| BASF | Joncryl additive systems | 55-70% | 10% | $375M annually |

Customized Chemical Solutions

Formulators increasingly develop bespoke chemical packages addressing specific application challenges. For humid coastal regions, customized binder blends resist microblistering through enhanced crosslinking density. Industrial maintenance coatings incorporate anticorrosive zinc phosphate at 18-25% loadings plus cellulose thickeners optimized for vertical surface application. Automotive refinish systems employ specialized rheology modifiers achieving 12-second Sagiscan measurements - critical for flawless clearcoat finishes.

Temperature-specific formulations demonstrate advanced problem-solving: Products for Middle Eastern markets integrate UV-resistant hindered amine light stabilizers (HALS) at 1.2-3.0% concentrations, doubling service life in 50°C environments. Conversely, Scandinavian exterior paints feature flexible copolymer binders maintaining integrity at -40°C, incorporating nanoporous pigments that enhance insulation properties by 15-18%.

Application Case Studies

London's Canary Wharf Tower project demonstrated the value of optimized chemistry when coating 1.2 million square feet at 220 meters elevation. Contractors employed a customized alkyd-acrylic hybrid incorporating thixotropic cellulose additives that enabled single-coat application despite frequent wind exposure. This formulation reduced project time by 40% while achieving 0.92 dry film thickness consistency, extending projected maintenance cycles to 15 years.

In manufacturing, automotive plants implement electrocoat systems containing precisely tuned epoxy-amine formulations. One German facility reported a 17% reduction in reject rates after switching to a new zinc-free pretreatment system with optimized silicate chemistry. The coating achieved 100% coverage on complex geometries while reducing sludge formation by 23 metric tons annually.

Sustainable Chemistry Innovations

The industry shift toward circular chemical models is accelerating dramatically. Bio-acrylics derived from soybean oils now capture 18% of the industrial binder market, growing at 7% annually. Waterborne technologies dominate architectural segments at 82% market penetration, reducing typical VOC content from 350g/L to under 50g/L since 2003. Technologies like micro-encapsulated catalysts enable low-temperature curing (75°C vs. traditional 130°C), achieving energy savings of 2.3 kWh per coated vehicle.

Cellulose for paints represents particularly promising developments: High-purity carboxylated cellulose stabilizers now demonstrate zero persistent organic pollutant profiles while maintaining shelf life stability. Trials with nanocellulose reinforcements show 30% improvements in film toughness at 5% loading, potentially replacing synthetic plastics in future composites.

Innovations in Chemicals for Paints

Cutting-edge research promises revolutionary developments: Self-healing polyurethane systems incorporating microencapsulated dicyclopentadiene demonstrate autonomous scratch repair at 40μm scale. Antimicrobial surface chemistries using zinc pyrithione nanoparticles provide 99.9% bacterial reduction without biocidal leaching. Photochromic pigments activated at specific UV wavelengths open possibilities for smart architectural finishes.

Digital technologies now transform formulation science: BASF's digital twin platform accelerated new waterborne primer development from 24 to just 14 months through predictive modeling of colloidal interactions. Quantum chemical computations now accurately forecast pigment-binder interactions at molecular scales, enabling first-pass-success formulation rates to rise from 19% to 64% within five years. Cellulose derivative modifications remain crucial as formulators balance performance with circular economy objectives, with global R&D spending topping $2.1 billion annually across the paint chemicals sector.

(chemicals used in paints )

FAQS on chemicals used in paints

Q: What types of chemicals are commonly used in paints?

A: Paints typically contain binders like acrylic resins, pigments such as titanium dioxide, and solvents like water or turpentine. These chemicals provide color, durability, and application ease.

Q: Why are solvents essential in paint formulations?

A: Solvents dissolve or disperse the binders and pigments, enabling smooth application and drying. They control viscosity and prevent premature drying.

Q: How is cellulose utilized in paint production?

A: Cellulose derivatives like nitrocellulose act as binders to form protective films and enhance adhesion. They improve durability and finish quality.

Q: What additives are included in paint chemicals?

A: Additives like surfactants prevent settling, while biocides inhibit mold growth. These enhance performance and extend shelf life.

Q: How do chemical binders differ from cellulose derivatives in paints?

A: Chemical binders include synthetic polymers for flexibility, whereas cellulose offers renewable options but requires specific solvents. Both ensure film integrity.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025