Cellulose ester, also known as hydroxypropyl methylcellulose (HPMC), is a versatile material with a wide range of applications in various industries. HPMC is a semi-synthetic polymer derived from cellulose, which is the main component of plant cell walls. This unique material has gained popularity due to its biodegradability, non-toxicity, and excellent film-forming properties.

.

In the food industry, HPMC is commonly used as a food additive and thickening agent. Its ability to form stable gels and increase viscosity makes it a popular choice for products such as sauces, soups, and dairy products. HPMC is also used in the production of edible films and coatings, where it helps to improve the shelf life of products by providing a barrier against oxygen and moisture.

cellulosa esther (hpmc)

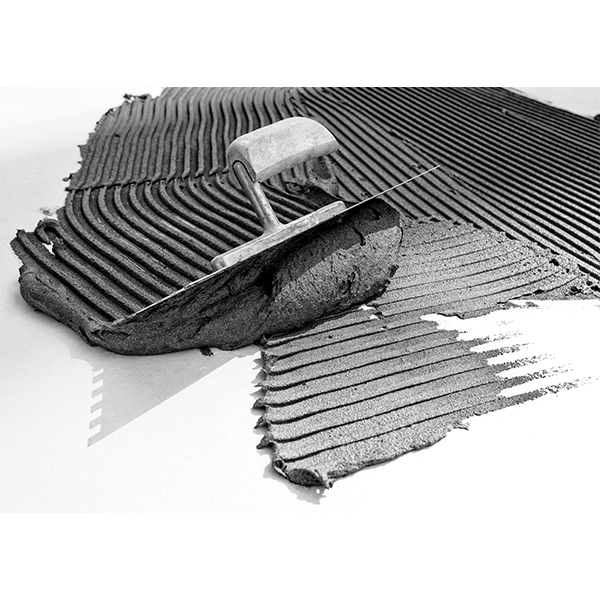

HPMC is also widely used in the construction industry, where it is used as a thickener in cement-based mortars, plasters, and grouts. The addition of HPMC helps to improve the workability and adhesion of these materials, making them easier to apply and more durable. Its water-retaining properties also help to prevent the premature drying of cement-based products, ensuring a strong and long-lasting bond.

In the cosmetics industry, HPMC is used in a variety of products such as creams, lotions, and hair care products. Its film-forming properties help to create a smooth and even texture, while its water-soluble nature makes it easy to wash off. HPMC is also used as a thickening agent in cosmetics, where it helps to improve the stability and consistency of products.

Overall, cellulose ester, or HPMC, is a versatile material with a wide range of applications across various industries. Its biodegradability, non-toxicity, and excellent film-forming properties make it a popular choice for use in pharmaceuticals, food, construction, and cosmetics. As technology continues to advance, the demand for HPMC is likely to increase, driving further research and innovation in the field of polymer science.

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025