HPMC A Comprehensive Look at Hydroxypropyl Methylcellulose

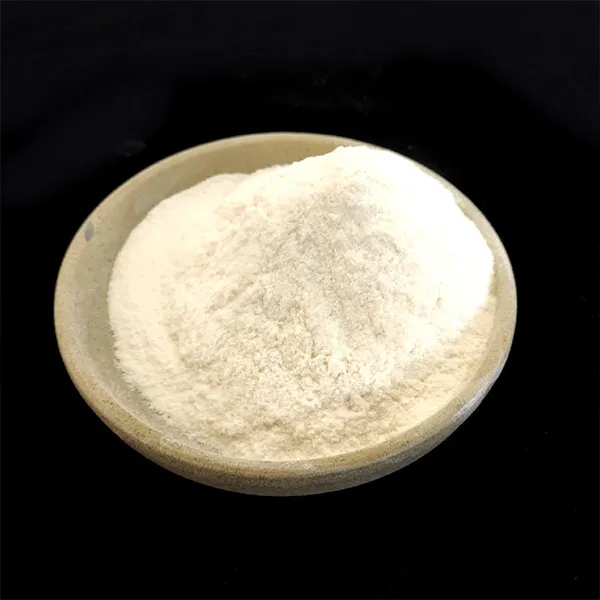

Hydroxypropyl Methylcellulose (HPMC), also known as cellulosic ether, is a widely utilized polymer derived from cellulose. Its unique properties make it an important substance in various industries, including pharmaceuticals, food, construction, and cosmetics. This article explores the production, characteristics, applications, and benefits of HPMC, highlighting why it has become a go-to material in many fields.

Production of HPMC

HPMC is produced through the modification of cellulose, a natural polymer obtained from plant fibers. The process begins with the treatment of cellulose with propylene oxide and methyl chloride, resulting in hydroxypropyl and methoxy groups being introduced into the cellulose structure. This modification enhances the solubility of cellulose in water and improves its functional properties. The degree of substitution (DS) of hydroxypropyl and methyl groups can be controlled during production, allowing for a range of product specifications tailored for specific applications.

Properties of HPMC

One of the standout features of HPMC is its solubility in water, which varies depending on the degree of substitution. HPMC can produce clear solutions, which are stable over a range of temperatures and pH levels. It possesses excellent film-forming abilities, viscosity characteristics, and emulsifying properties. Additionally, it is non-toxic, biodegradable, and free from animal-derived components, making it suitable for vegan and vegetarian applications.

HPMC also exhibits thermal gelling properties and can form gels at high temperatures, which has implications for its use in food products and pharmaceuticals. Furthermore, it provides controlled release of active ingredients in formulations, making it highly valued in drug delivery systems.

Applications of HPMC

HPMC’s versatility enables its use across multiple industries

1. Pharmaceuticals In the pharmaceutical industry, HPMC is frequently used as a binder, film coating agent, and controlled-release agent in tablet formulations. Its ability to form gels and maintain drug stability makes it essential for both solid and liquid dosage forms.

cellulos ether hpmc

2. Food Industry HPMC serves as a thickener, emulsifier, and stabilizer in various food products. It can improve the texture of processed foods, enhance moisture retention, and control the release of flavors. Its non-caloric nature also makes it desirable for low-calorie and reduced-fat foods.

3. Construction HPMC is commonly employed in construction materials such as tile adhesives, plasters, and dry-mix mortars. Its water-retention properties enhance the workability and adhesion of these materials, ensuring better performance.

4. Cosmetics and Personal Care In the cosmetics industry, HPMC acts as a thickening, emulsifying, and stabilizing agent in lotions, creams, and gels. Its ability to improve the texture and appearance of cosmetic products contributes to a better consumer experience.

Benefits of HPMC

The use of HPMC in various applications offers numerous advantages

- Versatility HPMC can be tailored for specific applications through manipulation of its degree of substitution, allowing for customized solutions in diverse industries.

- Safety and Stability As a non-toxic and stable compound, HPMC is suitable for use in sensitive applications, including pharmaceuticals and food products.

- Environmentally Friendly Being biodegradable and derived from renewable resources, HPMC presents an eco-friendlier choice compared to synthetic polymers.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) is a remarkable cellulosic ether that has gained prominence in numerous sectors due to its unique properties and versatility. From pharmaceuticals to food, construction, and cosmetics, HPMC’s range of potential applications showcases its operational benefits and adaptability. As industries continue to seek sustainable and efficient materials, HPMC is poised to play a crucial role in the ongoing development of innovative formulations and products.

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025