The Role of Hydroxypropyl Methylcellulose (HPMC) in Chemical Adhesives

Hydroxypropyl Methylcellulose (HPMC) is a versatile compound widely used in various applications, particularly in the formulation of chemical adhesives. As a cellulose ether, HPMC is a non-ionic, water-soluble polymer that offers unique properties, making it a popular choice among manufacturers and formulators in the adhesive industry. This article explores the significance of HPMC in chemical adhesives, its properties, benefits, and potential applications.

Understanding HPMC

HPMC is derived from cellulose, the most abundant organic polymer on Earth, through a chemical modification process. Its structure consists of a hydrophilic hydroxypropyl group and a hydrophobic methyl group, providing a balance between solubility and adhesion properties. This unique structure contributes to its effectiveness as a thickening agent, stabilizer, and film-forming agent in adhesive formulations.

Benefits of HPMC in Adhesives

1. Enhanced Adhesive Performance HPMC improves the tack, viscosity, and overall performance of adhesive formulations. It helps create a robust bond between surfaces, ensuring that the adhesive adheres effectively to various substrates, including wood, metal, plastic, and ceramics.

2. Controlled Release Properties In certain formulations, HPMC can provide a controlled release of active ingredients. This feature is particularly beneficial in applications such as controlled drug delivery systems, where a gradual release of the adhesive or active component is essential.

3. Water Resistance Although HPMC is water-soluble, its film-forming properties can lead to the creation of water-resistant layers when dried. This characteristic is advantageous for adhesives that are intended for use in humid environments or require durability against moisture.

chemic adhes hpmc

4. Thermal Stability HPMC exhibits excellent thermal stability, allowing adhesive formulations to maintain their performance across a range of temperatures. This property is crucial in applications where temperature fluctuations may occur.

5. Environmental Friendliness HPMC is biodegradable and non-toxic, making it an environmentally friendly option. In an era where sustainability is a primary concern, the use of HPMC-based adhesives can help manufacturers meet eco-friendly standards.

Applications of HPMC-Based Adhesives

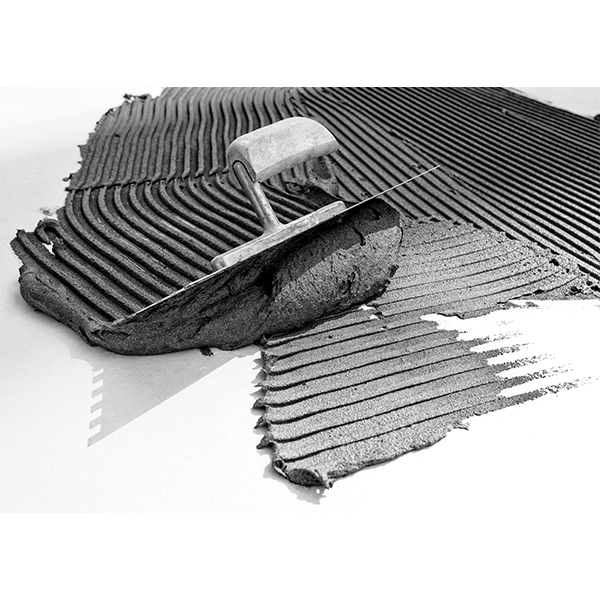

HPMC is utilized in a wide array of adhesive applications across different industries. In the construction sector, it is often employed in tile adhesives, joint compounds, and grouts due to its excellent binding properties and water retention capabilities. The automotive industry benefits from HPMC-based adhesives in manufacturing processes, ensuring strong bonds in various components while enhancing the overall structural integrity.

In the packaging industry, HPMC is used in adhesive formulations for labels and packaging materials. Its ability to bond effectively to different surfaces while maintaining clarity and flexibility is essential for the performance of packaging solutions. Moreover, HPMC is increasingly finding its way into the cosmetics and personal care sector, where it serves as an adhesive component in products such as gels, creams, and ointments.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) stands out as a valuable ingredient in the formulation of chemical adhesives due to its exceptional properties and versatility. As industries continue to prioritize performance, sustainability, and adaptability, HPMC will likely play an increasingly vital role in the development of advanced adhesive technologies. Its combination of environmentally friendly characteristics and reliable adhesive performance positions HPMC as a critical component in meeting the demands of various applications, ensuring strong and lasting bonds across multiple sectors.

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025

-

Construction Adhesive StrengthNewsAug.29,2025