Exploring the Versatility of Cellulose Ether in China

Cellulose ether, a versatile and essential derivative of cellulose, has garnered significant attention in various industries in China. With its wide range of applications, from pharmaceuticals and food to construction and cosmetics, cellulose ether is a critical component that exhibits unique properties such as thickening, binding, and stabilizing.

What is Cellulose Ether?

Cellulose ether is produced by chemically modifying cellulose, a natural polymer derived from plant cell walls. The modification process introduces various functional groups, transforming it into a soluble form. This solubility allows cellulose ether to be used in diverse applications. Some common types of cellulose ethers include hydroxypropyl methylcellulose (HPMC), methylcellulose (MC), and carboxymethyl cellulose (CMC). Each type has distinct characteristics that cater to specific industrial needs.

Applications in the Pharmaceutical Industry

In the pharmaceutical sector, cellulose ether plays a crucial role as a binder, thickener, and controlled-release agent. It is often used in tablet formulations to enhance the processing properties and stability of active pharmaceutical ingredients (APIs). The ability of cellulose ether to form gels upon hydration makes it ideal for use in sustained-release formulations, allowing for a gradual release of medication, which improves patient compliance and therapeutic efficacy.

Role in Food Industry

The food industry has also embraced cellulose ether for its functional benefits. It serves as a thickening agent, stabilizer, and emulsifier in various food products, including sauces, dressings, and baked goods. Its ability to improve texture while maintaining the volume of low-calorie products is particularly valuable. Additionally, cellulose ether can help retain moisture, enhancing the shelf-life and quality of food products. As consumers become increasingly health-conscious, cellulose ether provides a clean-label ingredient that meets the demand for natural and functional food additives.

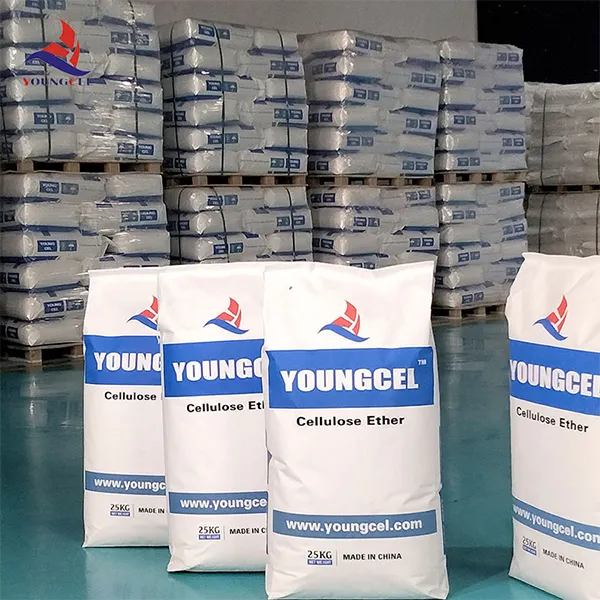

china cellulose ether

Impact on Construction Industry

The construction industry in China has leveraged the properties of cellulose ether to enhance the performance of building materials. HPMC is widely used in cement-based products, such as tile adhesives and plaster. Its water-retaining property ensures adequate hydration of cement, leading to improved workability, adhesion, and durability of the finished product. As China continues to invest in infrastructure and construction projects, the demand for high-quality cellulose ether is expected to rise significantly.

Cosmetic Applications

In cosmetics, cellulose ether is valued for its thickening and film-forming properties. It is commonly found in creams, lotions, and gels, providing improved texture and stability to formulations. Additionally, cellulose ether helps enhance the sensory properties of cosmetic products, offering a desirable feel and spreadability on the skin. As the cosmetics market in China continues to expand, manufacturers are increasingly incorporating cellulose ether to meet consumer demands for innovative and high-performing products.

Environmental Considerations

Sustainability is a growing concern in China, and the production of cellulose ether aligns well with this trend. Being derived from renewable resources, cellulose ether offers an environmentally friendly alternative to synthetic polymers. The ongoing research and development in cellulose ether production are focused on enhancing sustainability while maintaining performance. Innovations in processing methods can lead to lower energy consumption and waste reduction.

Conclusion

With its diverse applications across various sectors, cellulose ether stands out as a vital ingredient in modern industry. China's booming economy and increasing focus on sustainability present significant opportunities for the expansion of cellulose ether markets. As industries continue to seek innovative solutions, cellulose ether is poised to play an even more prominent role in enhancing product performance and meeting consumer demands in the years to come. Understanding and harnessing the potential of cellulose ether will be key for industries looking to thrive in a competitive landscape.

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose ThickenerNewsSep.01,2025

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025