Construction-Grade MHEC for Paints: What Buyers Need to Know (From the Factory Floor)

If you work in architectural coatings or dry-mix, you’ve probably heard the chatter around Factory Sale Construction Grade MHEC Technical Grade for Paint Cellulose Ether MHEC. To be honest, I didn’t expect to see this much demand from mid-sized paint makers—yet many customers say the balance of viscosity control, workability, and water retention has been a quiet productivity win.

Quick facts and origin

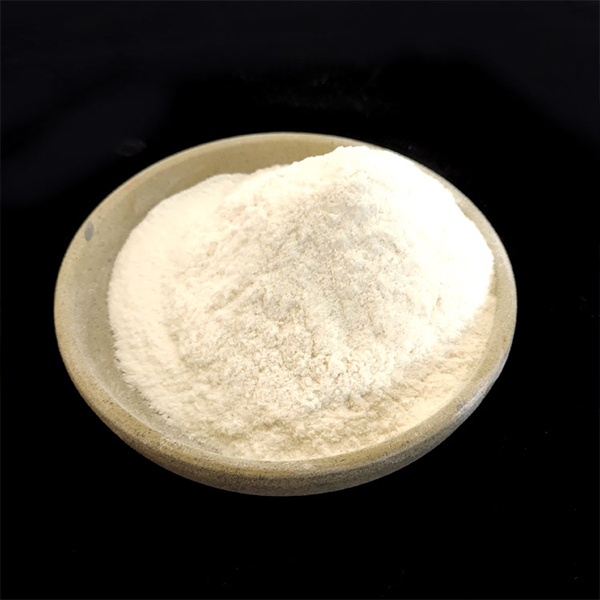

Brand: YoungCel | Model: YFPA-150 | CAS No.: 9032-42-2 | Colour: white to cream | Origin: No.1 Shifu East Road, Gaocheng District, Shijiazhuang, Hebei, China. In fact, the plant sits near a robust cellulose supply chain—useful when consistency matters week after week.

Typical specifications (technical grade)

| Chemistry | Methyl Hydroxyethyl Cellulose (MHEC) |

| Viscosity (2% sol., Brookfield RV, 20°C) | ≈150,000 mPa·s (YFPA-150); options ~25k–200k |

| Moisture | ≤5% |

| Ash | ≤5% |

| pH (1% sol.) | 6.0–8.5 |

| Methoxy / Hydroxyethyl | ≈19–24% / 4–12% (real-world use may vary) |

| Gel temperature | ~60–90°C |

| Particle size | ≥98% pass 80 mesh |

| Bulk density | ~350–550 kg/m³ |

| Shelf life | 24 months, sealed, dry place |

Where it’s used and why it’s trending

Factory Sale Construction Grade MHEC Technical Grade for Paint Cellulose Ether MHEC turns up in interior/exterior latex paints, putties/skim coats, gypsum-based plasters, tile adhesives (C1/C2), and waterproof mortars. Drivers? Water retention (less cracking), sag resistance, smooth brushing/rolling, stable viscosity under shear. Sustainability also nudges adoption—low odor, low VOC formulations benefit.

Process flow (how it’s made, briefly)

Materials: refined cellulose, NaOH, methyl chloride, ethylene oxide, purified water. Methods: alkalization → etherification → neutralization → washing → drying → milling → sieving. Testing: Brookfield viscosity per ASTM D2196, moisture/ash, substitution levels, pH. Batches are retained, which—speaking from visits—really helps traceability.

Application notes

- Paints: 0.2–1.0% on total formula; add to water phase with good agitation to avoid fisheyes.

- Dry-mix mortars: 0.2–0.6% by weight of binder; mix dry first, then water. Expect open-time gains.

- Testing: sag per ASTM D4400; scrub per ASTM D2486; viscosity per ASTM D2196.

Service life in-use: coatings show stable viscosity for 12–24 months in sealed cans; mortars keep workability 2–4 hours, depending on cement and temperature.

Real-world results

Case A (Southeast Asia, interior matte): after switching to Factory Sale Construction Grade MHEC Technical Grade for Paint Cellulose Ether MHEC, lab data showed 35% sag reduction and smoother leveling at equal PVC; Brookfield 2% solution held within ±7% over 3 months.

Case B (EU, C1 tile adhesive): dosage 0.35% improved open time by ~12–15 minutes and reduced slip by one class under EN 12004 checks. Feedback was “easier trowel feel,” which, surprisingly, also cut site waste.

Vendor comparison (indicative)

| Vendor | Origin | Lead time | Viscosity options | Certs | Price/kg ≈ |

|---|---|---|---|---|---|

| YoungCel (YFPA-150) | Hebei, China | 7–12 days | 25k–200k mPa·s | ISO 9001; REACH-ready | $2.2–$3.1 |

| Trader A | Imported mix | 3–5 weeks | Limited grades | — | $2.8–$3.8 |

| Brand B (EU) | EU | 2–3 weeks | Broad, premium | ISO 9001/14001 | $3.5–$5.2 |

Note: pricing and timing are indicative; always confirm current quotes.

Customization and compliance

YoungCel offers tailored viscosity windows, surface treatment for faster dissolution, and sieve cuts. Compliance-wise, look for ISO 9001, VOC-aligned paint use (EU 2004/42/EC), and REACH registration where required. Packaging is typically 25 kg multi-layer bags with PE liner—good moisture barrier, I guess, but store off the floor.

Final take

For balanced rheology and cost control, Factory Sale Construction Grade MHEC Technical Grade for Paint Cellulose Ether MHEC is a solid, factory-direct pick—especially if you need quick lead times and consistent sag/leveling performance without over-complicating the formula.

- ASTM D2196 – Standard Test Method for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield) Viscometer: https://www.astm.org/d2196

- ASTM D4400 – Standard Test Method for Sag Resistance of Paints: https://www.astm.org/d4400

- ASTM D2486 – Scrub Resistance of Interior Wall Paints: https://www.astm.org/d2486

- EN 12004 – Adhesives for tiles, definitions and specifications: https://standards.iteh.ai/catalog/standards/cen/9f8c3da1-a0b6-4e8b-b8b4-2bff4a52b6b6/en-12004

- ISO 9001:2015 Quality management systems; EU REACH Regulation (EC) No 1907/2006; EU Paints VOC Directive 2004/42/EC

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025