Building Coating Adhesive The Role of HPMC in Modern Construction

In the rapidly evolving construction industry, there is a constant demand for innovative materials that can enhance the durability, efficiency, and sustainability of building projects. Among these, building coating adhesives play a crucial role, significantly influencing the performance and longevity of various structures. One of the most important components that contribute to the effectiveness of these adhesives is Hydroxypropyl Methylcellulose (HPMC). This article explores the significance of HPMC in building coating adhesives and its benefits to modern construction.

HPMC is a non-ionic, water-soluble polymer derived from cellulose. It possesses unique properties that make it an ideal choice for a variety of applications, particularly in the construction sector. As an additive in building coating adhesives, HPMC enhances the performance of the adhesive in multiple ways, resulting in improved application and long-term durability of the coatings.

Building Coating Adhesive The Role of HPMC in Modern Construction

Moreover, HPMC provides excellent workability and thixotropic properties. This means that the viscosity of the adhesive can be altered under shear stress, making it easier to apply. For contractors, this translates into smoother and more uniform application, reducing the likelihood of defects in the finished product. The thixotropic nature of HPMC also helps to prevent sagging during applications on vertical surfaces, ensuring a neat and professional finish.

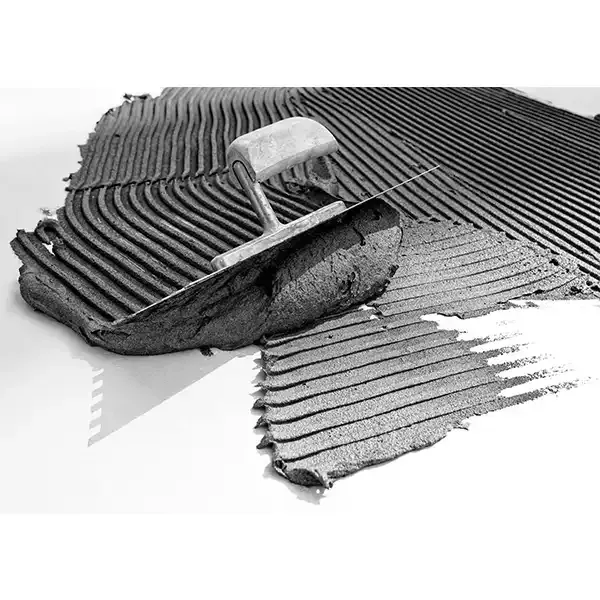

building coating adhesive hpmc

In addition to its application benefits, HPMC contributes to the overall performance of building coating adhesives in terms of bonding strength and flexibility. Coatings that incorporate HPMC exhibit enhanced adhesion to various substrates, including concrete, brick, and tiles. Furthermore, the flexibility imparted by HPMC allows the coatings to accommodate slight movements in the structure without cracking or losing grip, an essential attribute in areas prone to thermal expansion or vibrations.

In terms of sustainability, HPMC also stands out as an environmentally friendly additive. It is biodegradable and considered safe for health, making it an excellent choice for modern construction practices that emphasize reducing environmental impact. By incorporating HPMC into building coating adhesives, manufacturers can produce eco-friendlier products that still meet high-performance standards.

Another significant aspect of HPMC is its role in improving the aesthetics of building coatings. HPMC can enhance the uniform distribution of pigments within the adhesive, resulting in more vibrant colors and better opacity. This characteristic is especially important in decorative applications, where visual appeal is paramount.

In conclusion, Hydroxypropyl Methylcellulose (HPMC) is an indispensable ingredient in building coating adhesives, contributing to enhanced performance, better workability, and sustainability. As the construction industry continues to innovate and adapt to higher standards, HPMC stands out as a versatile solution that meets the growing needs for efficiency, durability, and environmental responsibility. As builders and manufacturers increasingly recognize the value of HPMC, its application will likely expand, further solidifying its role as a cornerstone in modern construction materials.

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025