Field Notes on a Workhorse Material: PVA 1788/2488 That Actually Delivers

I’ve tested more than a few binders and emulsifiers this year, and one product kept coming up in conversations with packaging and construction folks: High Purity 99% Pva Industrial Grade Polymer Powder Polyvinyl Alcohol Pva Good Price Pva 1788 2488 Powder. The name is a mouthful, I know, but the performance is what matters. In short, it’s a dependable PVOH for adhesives, cement modifiers, paper sizing, and even a few niche emulsification jobs. And yes, the price looks friendly without cutting corners.

What It Is (and why 1788/2488 matters)

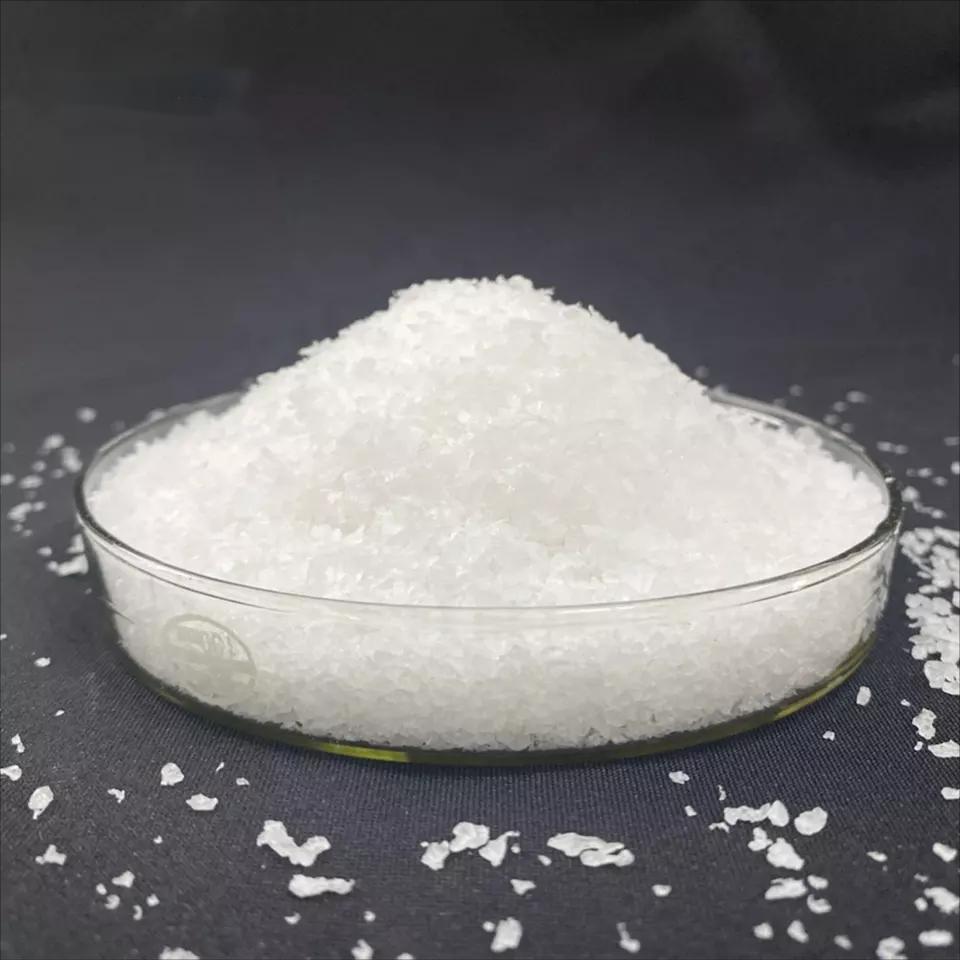

This PVA shows up as a white powder or flake—clean, low-odor. Grades 1788 and 2488 refer to viscosity and degree of hydrolysis: think 88% hydrolysis, mid-viscosity behavior that dissolves reliably and delivers film strength without being fussy. Many customers say it blends smoother than they expected, especially in room-temp pre-wets before hot water addition. Origin? No.1 Shifu East Road, Gaocheng District, Shijiazhuang, Hebei, China.

Product Specifications (quick view)

| Parameter | 1788 | 2488 | Test standard |

|---|---|---|---|

| Purity | ≈99% | ≈99% | ISO 15023-1; JIS K 6726 |

| Degree of hydrolysis | 88% ±1% | 88% ±1% | JIS K 6726 |

| Viscosity (4% aq., 20°C) | ≈17–27 mPa·s | ≈23–30 mPa·s | ISO 15023-1 |

| Ash | ≤0.5% | ≤0.5% | JIS K 6726 |

| Volatile | ≤5% (real-world may vary) | ≤5% | JIS K 6726 |

| Form | White powder/flake | White powder/flake | Visual |

Where it’s used (and why teams pick it)

- Adhesives and glues: handles paper, wood laminates; good film strength and tack.

- Construction: cement/gypsum modifiers; better workability and reduced dust-off.

- Emulsifiers/Dispersants: stable emulsions in polymerization aids and pigment slurries.

- Paper/Textile: surface sizing and warp sizing; clean burn-out, neat finish.

Customer feedback? “Dissolves cleaner than our previous lot” came up twice. Another user mentioned fewer foam issues than expected—nice bonus.

Process flow, QC, and service life

Materials and methods: vinyl acetate polymerization → alcoholysis to PVOH → drying → milling → sieving → packaging. QC checks typically include viscosity (ISO 15023-1), degree of hydrolysis and volatile content (JIS K 6726), pH and ash. Service life: around 24 months in sealed bags, cool/dry storage. Once in solution, I’d use within 48–72 hours for consistent rheology.

Certifications commonly provided: ISO 9001, REACH and RoHS statements on request. Mechanical film tests may follow ASTM D638 for tensile properties when relevant.

Vendor snapshot (pricing and options)

| Vendor | Typical grades | Purity | MOQ | Lead time | Certs |

|---|---|---|---|---|---|

| Youngcel (Hebei) | 1788, 2488 | ≈99% | As low as 1 MT | 7–15 days | ISO, REACH, RoHS |

| Vendor A | 1788, 1799 | ≥98.5% | 3 MT | 15–20 days | ISO |

| Vendor B | 2488, 2499 | ≈99% | 2 MT | 10–18 days | ISO, partial REACH |

Customization and a quick case

Customization usually revolves around viscosity windows (say 15–30 mPa·s), particle size, and bagging (25 kg or jumbo). If you need specific dissolution curves or anti-foam guidance, ask upfront—saves a headache later.

High Purity 99% Pva Industrial Grade Polymer Powder Polyvinyl Alcohol Pva Good Price Pva 1788 2488 Powder recently replaced a legacy binder in a tile-adhesive line. Result: more consistent open time and slightly better slip resistance; lab sheets showed viscosity stability over 72 hours with negligible ash drift. Not a moonshot, but quietly effective.

Final take

If you want a steady, no-drama PVA with solid QC and sensible pricing, this is a safe bet. Actually, that’s the story here—reliability first, nice economics second.

Authoritative references

- ISO 15023-1:2001 Plastics — Poly(vinyl alcohol) (PVOH) — Determination of viscosity number.

- JIS K 6726:1999 Poly(vinyl alcohol) resins — Test methods.

- ASTM D638 Standard Test Method for Tensile Properties of Plastics.

- EU RoHS Directive 2011/65/EU; ECHA REACH guidance (latest consolidated versions).

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025