Industry Trends and the Role of High-Viscosity HPMC in Modern Construction

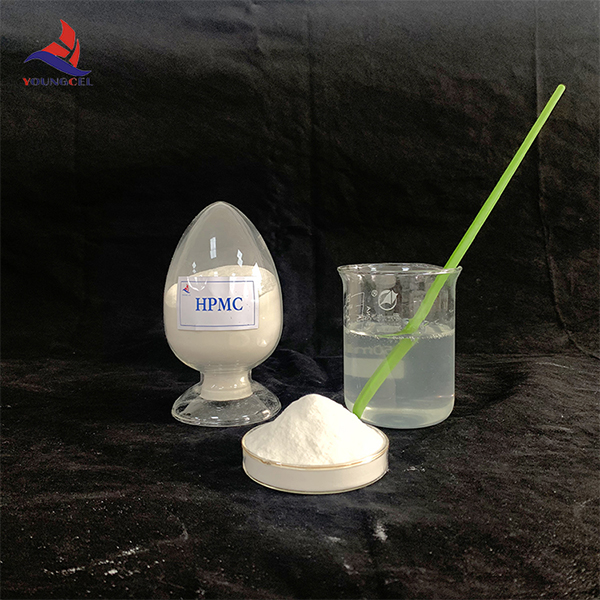

The global construction industry is undergoing a significant transformation, driven by an increasing demand for sustainable, durable, and high-performance building materials. This shift is fueled by stringent environmental regulations, a focus on energy efficiency, and the need for construction solutions that offer enhanced workability and longevity. Among the critical additives facilitating these advancements, high-viscosity Hydroxypropyl Methyl Cellulose (HPMC) stands out as an indispensable component.

Modern construction practices increasingly rely on sophisticated chemical admixtures to optimize material properties. HPMC, a versatile polymer derived from cellulose, plays a pivotal role in a wide array of building applications, including tile adhesives, renders, self-leveling compounds, and wall putties. The market trend indicates a growing preference for higher viscosity grades of HPMC due to their superior performance characteristics, such as enhanced water retention, improved rheology, and increased bond strength. This directly addresses the industry's need for materials that can withstand diverse climatic conditions, reduce material waste, and improve the overall structural integrity and aesthetic finish of construction projects.

Our focus is on the advanced properties and applications of High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder, a product engineered to meet these evolving industry demands. Its tailored attributes provide crucial benefits in modern construction formulations, ensuring superior performance and reliability.

Technical Specifications and Performance Overview

Understanding the precise technical specifications of High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is paramount for B2B decision-makers and engineers. This specialized HPMC variant is designed to deliver exceptional performance in demanding construction environments, characterized by its high viscosity and consistent quality.

Key Parameters and Properties

Our High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is subjected to rigorous quality control measures, conforming to international standards like ISO 9001 and meeting specific performance criteria. The core properties that define its efficacy include:

- High Viscosity: Ranging typically from 75,000 to 200,000 mPa.s (Brookfield RV, 2% solution, 20°C), providing excellent thickening and anti-sagging properties.

- Superior Water Retention: Critical for extending open time, improving hydration of cementitious materials, and preventing premature drying.

- Enhanced Workability: Improves the plasticity and spreadability of mortars and renders, making application easier and more uniform.

- Increased Bond Strength: Contributes to stronger adhesion between materials, reducing debonding and improving overall durability.

- Excellent Film-Forming Properties: Provides a protective barrier, enhancing surface hardness and resistance to abrasion.

- Good Stability: Offers resistance to enzymatic degradation and maintains performance across varying pH levels.

Product Specification Table

Below is a detailed specification table for our premium High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder, showcasing typical values:

Manufacturing Process and Quality Assurance

The production of High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder involves a meticulously controlled chemical process to ensure consistent quality and performance. Our manufacturing adheres to stringent international standards, guaranteeing a product that meets the exacting demands of the construction industry.

Process Flow: From Raw Material to Finished Product

- Raw Material Sourcing: High-purity refined cotton cellulose is the primary raw material. Its quality is rigorously checked to ensure optimal polymerization characteristics.

- Alkalization: The cellulose is first treated with an alkaline solution (typically sodium hydroxide) to open up its structure, making it more reactive. This critical step occurs in a specialized reactor under controlled temperature and pressure.

- Etherification: The alkalized cellulose then reacts with methyl chloride and propylene oxide. This etherification process introduces methoxyl and hydroxypropoxyl groups onto the cellulose backbone, defining the specific properties of HPMC. The precise control over the molar substitution (MS) and degree of substitution (DS) directly influences the final product's viscosity and water retention capabilities.

- Neutralization and Purification: After etherification, the reaction mixture is neutralized, and unwanted by-products are removed through multiple washing stages with hot, deionized water. This purification step is crucial for removing salts and unreacted chemicals, ensuring a pure HPMC product.

- Drying: The purified HPMC slurry is then carefully dried to a specific moisture content using advanced drying technologies, such as flash drying or spray drying, to prevent thermal degradation and maintain particle integrity.

- Milling and Sieving: The dried HPMC is milled into a fine powder and then sieved to achieve the desired particle size distribution. This consistency is vital for good dispersibility and dissolution rates in end-user applications.

- Quality Control and Packaging: Throughout the entire process, multiple checkpoints are established for real-time analysis. The final product undergoes comprehensive testing, including viscosity, particle size, moisture content, and chemical composition, against established ISO and internal quality standards (e.g., ISO 14001 for environmental management). Only batches meeting all specifications are packaged into industrial-grade bags, ready for distribution.

Advantages in Typical Application Scenarios:

Our rigorous manufacturing process ensures that our High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder offers distinct advantages:

- Energy Saving: By improving the workability and open time of mortars, less effort is required for application, and fewer errors lead to rework, indirectly contributing to energy savings in construction cycles.

- Enhanced Corrosion Resistance: In cementitious systems, HPMC contributes to a denser matrix by improving hydration, which can indirectly enhance resistance to aggressive environments, thus improving the service life of structures.

- Extended Service Life: Products formulated with our HPMC exhibit improved adhesion, reduced cracking, and enhanced durability, contributing to a longer service life for the finished construction elements.

Diverse Application Scenarios

The versatility of High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder makes it an invaluable additive across a broad spectrum of construction applications. Its rheological modification, water retention, and bonding properties are essential in achieving high-quality, durable results.

- Tile Adhesives: Improves adhesion to various substrates, enhances open time, and provides excellent anti-sag properties for large and heavy tiles. It ensures robust bonding and prevents tile slippage, even in vertical applications.

- Renders and Plasters: Contributes to superior workability, prevents cracking, and enhances the bond strength to masonry. It allows for smoother application and a more consistent finish, reducing rework.

- External Thermal Insulation Composite Systems (ETICS/EIFS): Essential for both the adhesive and reinforcing mesh mortar layers. It significantly improves adhesion to insulation boards, enhances impact resistance, and provides excellent weatherability.

- Self-Leveling Compounds (SLCs): Regulates rheology, ensuring smooth flow and excellent leveling capabilities without segregation. It prevents bleeding and enhances surface finish, making it ideal for subfloor preparation.

- Wall Putties and Skim Coats: Improves smoothness, crack resistance, and workability. It allows for easy application and a fine finish, preparing surfaces for painting or wallpapering.

- Joint Fillers and Crack Repair Mortars: Provides excellent plasticity and adhesion, ensuring durable and seamless repairs. It minimizes shrinkage and improves resistance to movement.

- Water-Based Paints and Coatings: Acts as a thickener and stabilizer, improving brushability, preventing sagging, and enhancing pigment suspension.

These diverse applications underscore the critical role our HPMC plays in enhancing the performance, durability, and ease of application across various construction segments, from residential to large-scale industrial projects.

Technical Advantages and Performance Differentiation

The technical advantages of our High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder are rooted in its optimized molecular structure and stringent quality control, providing tangible benefits that differentiate it from standard cellulose ethers.

Core Advantages:

- Exceptional Rheology Modification: The high viscosity ensures superior thickening efficiency, providing excellent sag resistance in vertical applications and improved thixotropy, which translates to easier trowelability and reduced effort for applicators. This is particularly crucial in applications like heavy-duty tile adhesives and thick-layer renders.

- Extended Open Time and Adjustable Setting: Our HPMC significantly prolongs the open time of cementitious mortars, allowing more flexibility for workers to adjust and place materials without compromising bond strength. Simultaneously, it maintains a predictable setting time, essential for project scheduling.

- Enhanced Adhesion and Cohesion: By improving the water retention and film-forming properties, our HPMC fosters better hydration of cement, leading to increased bond strength to various substrates and improved internal cohesion of the mortar matrix, reducing delamination risks.

- Improved Crack Resistance: The polymeric network formed by HPMC reduces plastic shrinkage and improves the flexibility of the hardened mortar, thereby minimizing the formation of cracks, especially in large surface applications.

- Cost-Effectiveness through Optimized Formulation: While a premium product, its high efficiency means lower dosages are often required compared to lower-grade alternatives, leading to overall formulation cost savings and consistent performance.

- Consistent Quality and Dispersibility: Our manufacturing process ensures a highly uniform product with excellent dispersibility in water, preventing lump formation and ensuring homogeneous mixing, which is critical for consistent end-product performance.

Comparative Performance (High Viscosity vs. Standard Grade HPMC):

To further illustrate the advantages, consider the comparative performance against a standard viscosity HPMC:

Vendor Comparison and Customized Solutions

Selecting the right supplier for high-performance additives like High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is a critical decision for construction material manufacturers. Beyond product specifications, vendor capabilities in customization, technical support, and logistical efficiency are paramount.

Key Factors for Vendor Comparison:

- Product Consistency and Quality: Verify adherence to international standards (e.g., ISO, ASTM) and consistent batch-to-batch quality. Look for comprehensive quality control protocols and certifications.

- Technical Expertise and Support: A strong vendor offers more than just a product; they provide application guidance, troubleshooting, and formulation optimization support, backed by experienced chemists and engineers.

- Customization Capabilities: The ability to tailor HPMC properties (e.g., specific viscosity range, dissolution rate, surface treatment) to unique formulation requirements is a significant advantage.

- Supply Chain Reliability: Evaluate lead times, production capacity, logistics networks, and inventory management to ensure uninterrupted supply.

- Cost-Effectiveness and Value: Beyond unit price, consider the overall value proposition, including product performance, reduced dosage rates, and the impact on overall formulation costs and end-product quality.

- Certifications and Compliance: Ensure the vendor's products comply with relevant industry certifications (e.g., REACH, specific building material standards) and environmental regulations.

Our Approach to Customized Solutions:

Recognizing that no two construction formulations are identical, we specialize in providing tailored solutions. Our customization process for High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder involves:

- Detailed Needs Assessment: We work closely with clients to understand their specific application, substrate types, climate conditions, and desired performance outcomes.

- Laboratory Formulation and Testing: Our R&D team utilizes advanced laboratory equipment to develop and test HPMC variants with adjusted methoxyl and hydroxypropoxyl ratios, particle size distributions, and surface treatments to achieve precise rheological and hydration properties.

- Pilot Batch Production: Before full-scale manufacturing, pilot batches are produced for client evaluation and in-field testing, ensuring the customized product performs as expected under real-world conditions.

- Ongoing Technical Support: Our commitment extends beyond delivery, with continuous technical support to help clients optimize their formulations and overcome any application challenges.

This bespoke approach ensures that clients receive an HPMC solution perfectly integrated into their product lines, enhancing performance and driving market differentiation.

Application Case Studies: Real-World Performance

Our High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder has been successfully deployed in numerous demanding construction projects globally, demonstrating its superior performance and reliability. These case studies highlight the practical benefits and client satisfaction achieved through its application.

Case Study 1: High-Rise Building Tile Adhesion in a Tropical Climate

- Challenge: A leading construction firm in Southeast Asia required a tile adhesive for external cladding of a 40-story building. The tropical climate, characterized by high humidity and significant temperature fluctuations, necessitated an adhesive with exceptional water retention, long open time, and robust bond strength to prevent tile debonding and cracking.

- Solution: We collaborated with the client to formulate a high-performance tile adhesive utilizing our HPMC-HV150M (a 150,000 mPa.s viscosity grade). Its superior water retention extended the open time by 30% compared to previous formulations, while its excellent anti-sag properties ensured perfect alignment of large format tiles on vertical surfaces.

- Results: The project achieved outstanding adhesion test results (C2TE classification per EN 12004), significantly reducing material waste and ensuring the long-term integrity of the facade. The client reported improved workability and faster project completion due to the extended open time.

Case Study 2: Self-Leveling Underlayment for Industrial Flooring

- Challenge: An industrial flooring specialist needed a self-leveling compound that could provide a perfectly smooth, durable, and crack-free surface for a large factory floor with heavy machinery. The key challenges were achieving optimal flow characteristics without segregation and ensuring rapid strength development.

- Solution: Our HPMC-HV75M was incorporated into the self-leveling formulation. Its optimized molecular structure provided excellent rheology control, allowing for seamless flow and self-leveling over large areas, while preventing water separation and aggregate settlement.

- Results: The resulting self-leveling underlayment exhibited exceptional surface flatness and compressive strength, exceeding project specifications. The customer praised the ease of application and the high-quality, durable finish that significantly reduced installation time and improved overall floor performance under heavy loads.

These examples underscore our commitment to delivering high-quality, reliable solutions that meet the demanding requirements of modern construction.

Ensuring Trust: FAQ, Logistics, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: What is the primary benefit of using high-viscosity HPMC over standard grades?

- A: High-viscosity HPMC provides superior water retention, enhanced rheology control (anti-sagging, improved workability), and greater bond strength, particularly crucial for demanding applications like thick-bed tile adhesives, heavy renders, and external insulation systems where excellent stability and performance are required. It also often allows for lower dosages due to higher efficiency.

- Q: How does your High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder improve open time?

- A: The optimized molecular structure of our HPMC creates a polymeric film that effectively traps water within the mortar matrix, preventing premature evaporation. This extended water retention ensures cement hydration continues for a longer period, thus prolonging the open time for easier and more flexible application.

- Q: Is your HPMC compatible with other common construction additives?

- A: Yes, our HPMC is designed for excellent compatibility with a wide range of common construction additives, including redispersible polymer powders, defoamers, air entraining agents, and plasticizers. For optimal performance in specific formulations, we recommend conducting preliminary tests or consulting with our technical support team.

- Q: What is the typical shelf life and storage conditions for the product?

- A: Our HPMC typically has a shelf life of 24 months from the date of manufacture when stored in its original, unopened packaging in a cool, dry place, away from direct sunlight and moisture. Proper storage is crucial to maintain its performance characteristics.

Lead Time and Fulfillment

We understand the importance of timely delivery for your project schedules. Our standard lead time for High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is typically 7-14 business days for standard orders, depending on quantity and destination. For customized solutions or large-volume orders, lead times will be confirmed upon order placement. We operate a robust global logistics network to ensure efficient and reliable delivery.

Warranty and Quality Commitment

We stand by the quality of our products. Our High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder comes with a comprehensive warranty against manufacturing defects, ensuring it meets the specified technical parameters. This commitment is underpinned by our ISO 9001 certified quality management system, ensuring every batch undergoes stringent testing before shipment. Should any product fail to meet the agreed specifications, we are committed to providing a resolution in accordance with our terms of sale.

Customer Support and Technical Assistance

Our dedicated customer support team and experienced technical experts are available to provide comprehensive assistance, from product selection and formulation guidance to troubleshooting and post-purchase support. We believe in building long-term partnerships through unparalleled service. Contact us via email, phone, or through our website for prompt and professional assistance.

Conclusion and Authoritative References

The strategic integration of High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is pivotal for achieving superior performance in modern construction materials. Its advanced rheological properties, enhanced water retention, and improved bonding capabilities directly address the industry's demand for durability, workability, and efficiency. By choosing a high-quality HPMC supplier, B2B partners can ensure their formulations meet the highest standards, optimize material performance, and ultimately contribute to safer, more sustainable, and longer-lasting infrastructure.

Our commitment to stringent quality control, technical expertise, and tailored solutions positions us as a trusted partner in delivering advanced HPMC solutions that drive innovation and success in the global construction market.

References

- American Society for Testing and Materials (ASTM) International Standards.

- International Organization for Standardization (ISO) Standards.

- The European Union EN 12004 standard for Tile Adhesives.

- U.S. Pharmacopeia (USP) and European Pharmacopoeia (EP) Monographs for Hydroxypropyl Methylcellulose.

- Journal of Building Materials and Structures.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025