Inside the Mix: Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel

If you work in drymix, coatings, or gypsum, you already know the quiet hero is the cellulose ether. To be honest, the right grade can make a hard-to-apply mortar behave like a dream. The product here—made in Hebei, China, at No.1 Shifu East Road, Gaocheng District—lands squarely in that practical sweet spot many customers ask for: consistent viscosity, clean dissolution, and reliable water retention in both cement and gypsum systems.

What it is—briefly

The line spans HPMC/MHEC-type cellulose ethers (CAS 9004-65-3, EINECS 220-971-6). The base chemistry is hydroxypropyl methyl cellulose, but field users often group compatible grades under one “Walocel-type” umbrella. In fact, the Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel series is tuned for cement renders, tile adhesives, polymer-modified putties, and gypsum-based joint compounds.

Key Specifications (typical, real-world use may vary)

| Model | YFM-200 (HPMC/MHEC family) |

| Appearance / Color | Powder, pure white |

| Purity | ≈ 99% |

| Bulk density | 0.35–0.55 g/cm³ |

| Viscosity (2% sol., Brookfield) | 20,000–70,000 mPa·s (selectable grades) |

| Moisture | ≤ 5% |

| pH (2% sol.) | 6.0–8.5 |

| Ash | ≤ 5% |

| HS Code | 3912390000 |

| Packaging | 25 kg multiwall bags with PE liner |

| Shelf life | 24 months, dry/cool storage |

How it’s used (process flow)

- Materials: cement or gypsum base, mineral fillers, redispersible polymer (if used), additives, and Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel.

- Dry blending: 3–10 minutes in ribbon/paddle blender; cellulose added last to avoid agglomeration.

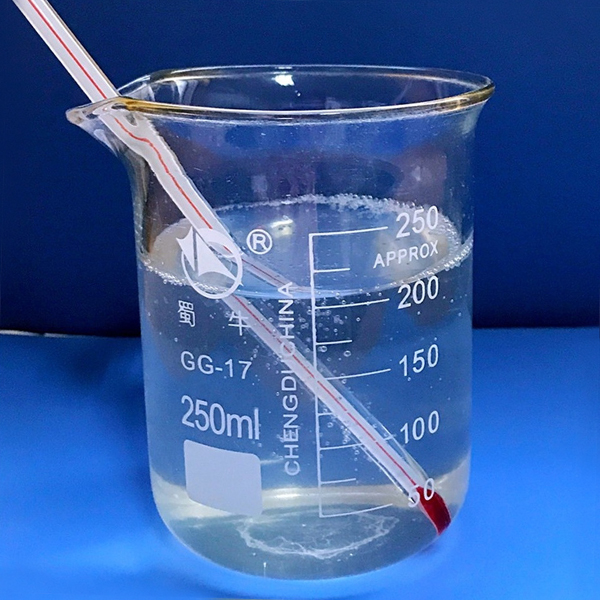

- Hydration: add water while mixing; allow 5–10 minutes maturing for full viscosity build.

- Testing: - EN 1015-18/ASTM C1437 flow for workability; - EN 12004 open time (tile ADH); - ASTM C472 for gypsum set; - EN 998-1 for renders.

- Service life in system: maintains water retention and slip resistance through workable open time; cured system durability follows base binder standard (e.g., EN 12004 categories).

Where it shines

- Cement renders/skim coats: better hang and trowel glide; reduced sag.

- Tile adhesives: open time extension and slip resistance, especially in warm climates.

- Gypsum putties/joint compounds: crack control via moisture retention; smooth finish.

- Powder coatings and primers: anti-sag and water retention at low dosages (≈0.2–0.6%).

Vendor comparison (indicative)

| Supplier | Viscosity stability | Water retention | Lead time | Certs |

|---|---|---|---|---|

| Youngcel (Hebei) | High (heat-aged) | ≈ 92–96% | 10–15 days | ISO 9001, REACH-ready |

| Tier-1 global | Very high | ≈ 94–97% | 2–6 weeks | ISO 9001/14001 |

| Generic import | Medium | ≈ 86–91% | 7–20 days | Varies |

Customization, QC, and feedback

Grades can be tuned for viscosity, substitution level, and surface treatment (fast-dissolving vs. delayed). Many customers say the delayed-hydration version cuts fish-eyes in high-speed batching. Internal lab data on YFM-200 showed open time gain of ≈8–14 minutes in C1 tile adhesive (EN 12004) versus control; gypsum joint compound saw 12–18% less edge cracking in accelerated dry boxes. Actually, the smoother trowel feel is what applicators notice first.

A quick field story

A coastal contractor swapped in Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel for an exterior skim coat. Same sand/cement ratio, 0.35% dosage. Workability window stretched by around 12 minutes at 28°C, and the crew reported less edge tearing. Not epic, but on large facades, that time cushion pays for itself.

Compliance and notes

Manufactured under ISO 9001 with traceable lots; conforms to typical drymix benchmarks used in EN 12004, EN 998-1, ASTM C472, and ASTM C1437 test schemes. Always validate in your own formulation—fillers, cement chemistry, and temperature shift results a bit.

Authoritative citations

- EN 12004: Adhesives for tiles — Requirements, evaluation of conformity.

- EN 998-1: Specification for mortar for masonry — Rendering and plastering mortar.

- ASTM C1437: Standard Test Method for Flow of Hydraulic Cement Mortar.

- ASTM C472: Standard Test Methods for Physical Testing of Gypsum Plasters and Gypsum Concrete.

- ISO 9001: Quality management systems — Requirements.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025