Introduction to Advanced Cellulose Ethers in Construction and Coatings

In the dynamic landscape of modern construction and high-performance coatings, the role of rheology modifiers and water retention agents is paramount. These specialized additives are critical for enhancing the workability, adhesion, and durability of a wide array of building materials. Among the most pivotal of these are cellulose ethers, particularly Methyl Hydroxyethyl Cellulose (MHEC) and Methyl Hydroxypropyl Cellulose (MHPC), commonly known by brand names such as Walocel. These compounds are extensively utilized for their unique ability to control water migration, improve consistency, and prevent sagging in various applications.

This article delves into the technical intricacies, market relevance, and application advantages of high-quality cellulose ethers, specifically focusing on the product: Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel. We will explore its manufacturing process, detailed technical specifications, diverse application scenarios, and the tangible benefits it brings to demanding B2B sectors. Understanding these parameters is crucial for professionals seeking to optimize product performance, reduce material waste, and ensure long-term structural integrity in their projects.

Industry Trends and Market Dynamics

The global market for cellulose ethers in construction is experiencing robust growth, driven by increasing urbanization, infrastructure development, and a rising demand for sustainable and high-performance building materials. According to recent market analyses, the cellulose ether market is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2023 to 2028, reaching significant valuation. Key drivers include the surge in dry-mix mortar production, the expansion of the plaster and render segment, and the continuous innovation in paint and coating formulations. There is a strong emphasis on environmentally friendly products, leading to a preference for bio-based additives like cellulose ethers that offer superior performance without compromising ecological standards. Furthermore, the stringent regulatory environment concerning volatile organic compounds (VOCs) in paints and coatings is pushing manufacturers towards water-based systems, where cellulose ethers play a crucial role in rheology modification and stabilization.

Understanding the Core Chemistry and Production Process of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel

The superior performance of cellulose ethers like MHEC and MHPC is rooted in a meticulously controlled manufacturing process that transforms natural cellulose into highly functional polymers. The product, Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel, exemplifies this advanced synthesis, ensuring consistent quality and performance across various applications.

Manufacturing Process Flow:

Step 1: Raw Material Preparation

- Cellulose Source: High-purity natural cellulose, typically derived from wood pulp or cotton linters, is selected. This raw material undergoes initial purification to remove impurities.

- Alkalization: The purified cellulose is steeped in a concentrated caustic soda (NaOH) solution. This process swells the cellulose fibers, converting them into alkali cellulose, which makes the hydroxyl groups more reactive for subsequent etherification.

Step 2: Etherification

- Methylation (for MHEC/MHPC): Methyl chloride (CH₃Cl) is introduced to react with the alkali cellulose, substituting some hydroxyl groups with methyl groups.

- Hydroxyethylation (for MHEC): Ethylene oxide (C₂H₄O) is reacted with the alkali cellulose to introduce hydroxyethyl groups.

- Hydroxypropylation (for MHPC): Propylene oxide (C₃H₆O) is reacted with the alkali cellulose to introduce hydroxypropyl groups.

- Controlled Reaction: The degree of substitution (DS) and molar substitution (MS) are precisely controlled during these reactions to achieve the desired viscosity, gelation temperature, and solubility characteristics of the final product.

Step 3: Neutralization and Washing

- The reaction mixture is neutralized with an acid to stop the etherification process and adjust the pH.

- Extensive washing with hot water is performed to remove by-products (e.g., sodium chloride) and unreacted reagents, ensuring product purity.

Step 4: Drying, Grinding, and Packaging

- The purified cellulose ether slurry is dried to a specific moisture content.

- It is then ground into a fine powder, and particle size distribution is carefully controlled to ensure optimal dissolution and performance in end-user applications.

- The final product undergoes rigorous quality control checks against ISO and ANSI standards for purity, viscosity, water retention, and other key parameters before being packaged.

Figure 1: Illustration of Cellulose Ether Manufacturing Process Stages

This intricate process ensures that Youngcel's Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel meets stringent quality requirements, offering high reproducibility and consistent performance. The emphasis on controlled etherification directly impacts critical properties such as water retention capacity, open time, sag resistance, and adhesion, which are vital for dry-mix mortars, cement paints, and gypsum-based formulations.

Technical Specifications and Performance Parameters

The performance of cellulose ethers like Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel is defined by a set of critical technical parameters. These specifications are crucial for formulators to select the appropriate grade for their specific application requirements, ensuring optimal results in terms of workability, adhesion, and durability.

Key Product Specifications:

| Parameter | Typical Value / Range | Test Method | Significance in Application |

|---|---|---|---|

| Viscosity (2% solution, Brookfield RVT, 20°C) | 10,000 - 100,000 mPa·s (adjustable) | ASTM D1347 | Crucial for workability, sag resistance, and open time in mortars and paints. Higher viscosity means better anti-sag properties. |

| Methoxy Content | 20.0 - 25.0 % | ISO 14467 | Influences solubility, gelation temperature, and hydrophobicity. |

| Hydroxyethyl / Hydroxypropyl Content | 3.0 - 8.0 % (for MHEC) / 4.0 - 12.0 % (for MHPC) | ISO 14467 | Controls water retention, gelation temperature, and compatibility with other additives. |

| pH (1% solution) | 5.0 - 8.0 | ASTM D1347 | Ensures compatibility and stability within alkaline cementitious systems. |

| Moisture Content | ≤ 5.0 % | ASTM D1347 | Indicates product stability and prevents caking during storage. Lower is better. |

| Particle Size (Residue on 80 mesh) | ≤ 5.0 % | ISO 787-7 | Affects dissolution rate and homogeneity in dry-mix formulations. Finer particles dissolve faster. |

| Water Retention Rate | ≥ 90% (typical in cementitious mortar) | Internal Method (based on EN 1015-8) | Critical for preventing rapid water loss, ensuring proper hydration of cement, extended open time, and improved bond strength. |

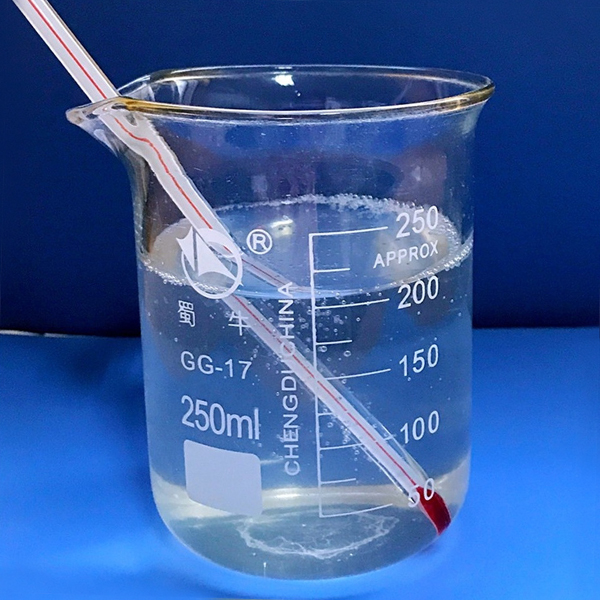

Figure 2: Advanced Analytical Equipment for Quality Control of Cellulose Ethers

These parameters are meticulously controlled during the manufacturing of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel to ensure optimal performance. For instance, the viscosity range is tailored for applications from tile adhesives requiring high anti-slip properties to self-leveling compounds demanding excellent flow. The water retention rate, typically measured by internal methods derived from international standards like EN 1015-8, directly correlates with the open time and bond strength of mortars, preventing premature drying and ensuring full hydration of cementitious binders.

Key Application Scenarios for Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel

The versatility and high performance of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel make it an indispensable additive across a broad spectrum of construction and coating applications. Its unique properties are leveraged to improve the workability, durability, and overall performance of diverse material formulations.

Target Industries and Applications:

-

Dry-Mix Mortars: This is a primary application area.

- Tile Adhesives (C1/C2 Grades): Provides excellent water retention, preventing rapid drying of the adhesive, extending open time, and enhancing bond strength to ceramic, porcelain, and natural stone tiles. It also contributes to sag resistance, crucial for vertical applications.

- Skim Coats and Wall Putties: Improves smoothness, ease of application, and adhesion to various substrates, creating a uniform surface for painting or decorative finishes. Minimizes cracking and improves water retention for proper drying.

- External Thermal Insulation Composite Systems (ETICS) Mortars: Essential for base coats and renders, providing cohesion, workability, and freeze-thaw stability. Enhances adhesion to insulation boards and minimizes cracking.

- Self-Leveling Compounds (SLCs): Regulates rheology, ensuring excellent flow and leveling properties while preventing segregation and bleeding.

-

Gypsum-Based Products:

- Gypsum Plasters: Improves workability, adhesion, and anti-sag properties on vertical surfaces. Controls setting time and enhances surface finish.

- Joint Fillers: Ensures smooth application, reduced shrinkage, and excellent crack resistance for finishing drywall joints.

- Cement-Based Paints and Coatings: Contributes to thickening, stabilization, and pigment suspension in water-based formulations. Improves brushability, roller application, and provides excellent film formation. Ensures color consistency and prevents settling of solids.

- Tile Grouts: Enhances workability, reduces shrinkage, and improves water retention for denser, more durable grout lines.

Figure 3: Cellulose Ether Enhancing Tile Adhesive Application in Modern Construction

In these diverse applications, the tailored grades of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel allow for precise control over key performance indicators such as open time, setting time, water demand, sag resistance, and adhesion strength, providing significant advantages to manufacturers and contractors alike.

Technical Advantages and Benefits

The selection of a high-quality cellulose ether is a critical decision for manufacturers aiming to differentiate their products in a competitive market. Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel offers a comprehensive suite of technical advantages that directly translate into improved product performance, efficiency, and cost-effectiveness for B2B partners.

Key Advantages:

- Superior Water Retention: This is the hallmark feature of MHEC/MHPC. By forming a protective film around cement or gypsum particles, it significantly reduces water evaporation and absorption by the substrate. This extended hydration time ensures the full development of mechanical strength and bond adhesion, particularly in hot and dry climates, preventing premature drying and cracking.

- Enhanced Workability and Open Time: The pseudoplastic (shear-thinning) rheology imparted by cellulose ethers makes mortars and paints easier to apply. They flow smoothly under shear stress (e.g., troweling, brushing) but thicken rapidly when at rest, preventing sag. The extended open time allows for easier adjustments and ensures better adhesion before the material sets.

- Excellent Sag Resistance and Anti-Slip Properties: For vertical applications such as tile adhesives or thick renders, sag resistance is crucial. High-viscosity grades of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel provide the necessary yield stress to hold heavy tiles or thick layers in place without slumping, thereby improving installation quality and efficiency.

- Improved Adhesion and Cohesion: By controlling water migration and providing lubrication, cellulose ethers enhance the bond strength between the mortar/paint and the substrate. They also improve the internal cohesion of the mix, leading to more durable and robust finished products.

- Rheology Modification: Beyond simple thickening, MHEC/MHPC provides thixotropic properties. This means materials become thinner when stirred or spread, and then regain their thickness when left undisturbed, which is ideal for pumpable mortars and spray applications, ensuring uniform coverage and reduced material waste.

- Freeze-Thaw Stability: In regions with fluctuating temperatures, the ability of building materials to withstand freeze-thaw cycles without degradation is vital. Cellulose ethers can contribute to improved freeze-thaw resistance by modifying the pore structure and reducing water absorption.

- Cost-Effectiveness and Material Optimization: By improving water retention and workability, formulators can often optimize other components of their mix, potentially reducing overall material consumption while maintaining or even improving performance. This translates into tangible cost savings and enhanced product value.

These technical advantages are not merely theoretical; they are proven in rigorous laboratory testing and extensive field applications, consistently delivering superior outcomes for manufacturers in the construction chemicals and paint industries.

Vendor Comparison and Differentiation

Selecting the right supplier for cellulose ethers is as crucial as selecting the right product. While many vendors offer MHEC and MHPC, Youngcel differentiates itself through a commitment to consistent quality, technical support, and customized solutions for Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel.

Comparative Analysis: Youngcel vs. Generic Suppliers

| Feature | Generic Supplier | Youngcel (for Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel) |

|---|---|---|

| Product Consistency | Variable batches, inconsistent viscosity, and water retention. | Rigorous QC, consistent specifications across all batches, ensuring predictable performance. |

| Technical Support | Limited or generalized support, minimal formulation guidance. | Dedicated team of chemists and application engineers, providing in-depth formulation advice and troubleshooting. |

| Customization Options | Typically off-the-shelf products, limited ability to tailor. | Extensive R&D capabilities for developing bespoke MHEC/MHPC grades based on specific customer needs (viscosity, substitution, particle size). |

| Certifications & Compliance | May lack comprehensive international certifications or adherence to standards. | ISO 9001 certified manufacturing, REACH compliance, adherence to relevant industry standards (e.g., ASTM, EN). |

| Supply Chain Reliability | Potential for disruptions, longer lead times, less secure sourcing. | Robust global logistics network, consistent inventory management, reliable delivery schedules. |

| Value Proposition | Price-focused, potentially leading to hidden costs from poor performance or rework. | Performance-driven, offering long-term value through enhanced product quality, reduced waste, and expert support. |

Figure 4: Youngcel's Advanced Research and Development Facility

Youngcel's long-standing presence in the industry, coupled with significant investment in R&D and quality assurance, positions it as a leading choice for partners seeking reliability and performance from their cellulose ether supplier. Our commitment extends beyond mere product delivery to becoming a strategic partner in our clients' success.

Customized Solutions and Product Development

Recognizing that every application has unique requirements, Youngcel offers bespoke solutions for Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel. Our technical team works closely with clients to develop custom grades tailored to specific formulation needs, environmental conditions, and desired performance characteristics. This includes:

- Viscosity Optimization: Adjusting viscosity ranges to match specific workability, sag resistance, or flow requirements.

- Substitution Degree Modification: Fine-tuning the balance between methyl, hydroxyethyl, or hydroxypropyl groups to alter gelation temperature, water retention, and compatibility.

- Particle Size Distribution: Controlling particle fineness for optimal dissolution rates in both dry-mix and liquid formulations.

- Performance Additives: Exploring synergistic effects with other additives to achieve multi-functional properties.

This collaborative approach ensures that our clients receive a product that is perfectly aligned with their technical specifications and commercial objectives, fostering innovation and achieving optimal results in their final products.

Real-World Application Case Studies

The practical effectiveness of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel is best demonstrated through its successful implementation in challenging real-world scenarios. These case studies highlight the tangible benefits and problem-solving capabilities of our advanced cellulose ethers.

Case Study 1: High-Performance Tile Adhesive for a Major Commercial Project

Client: A leading construction chemicals manufacturer in the Middle East.

Challenge: The client required a C2TE grade tile adhesive that could maintain extended open time (up to 30 minutes) and excellent sag resistance (no slip for 20 minutes with 10kg/m² tiles) in extreme hot and dry conditions (up to 45°C) for a large-scale commercial tower project involving heavy porcelain tiles on vertical surfaces. Existing cellulose ether suppliers struggled with consistency under these demanding environmental factors, leading to application difficulties and potential bond failures.

Solution: Youngcel provided a customized high-viscosity MHPC grade of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel, specifically engineered for enhanced water retention and rheology modification at elevated temperatures. Our technical team collaborated with the client's R&D to fine-tune the formulation.

Results:

- Open Time: Consistently achieved >35 minutes open time even at 40°C, significantly exceeding project requirements.

- Sag Resistance: Demonstrated zero sag for heavy tiles on vertical applications, ensuring secure and precise installation.

- Bond Strength: Improved adhesion strength by 15% compared to previous formulations, leading to a more reliable and durable installation.

- Application Efficiency: Contractors reported enhanced workability and ease of spreading, reducing labor time and material waste.

Figure 5: High-Rise Building Utilizing Advanced Tile Adhesives Formulated with Cellulose Ethers

This partnership resulted in a highly successful project completion, strengthening the client's market position and demonstrating Youngcel's capability to deliver high-performance solutions under challenging conditions. The product’s consistent quality provided significant energy saving benefits by reducing rework and ensuring optimal material utilization.

Ensuring Trust and Reliability: Certifications, Support, and FAQs

At Youngcel, building enduring trust with our B2B partners is paramount. We achieve this through transparent operations, adherence to international standards, comprehensive customer support, and robust quality assurances for our Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel.

Authoritative Certifications and Compliance:

- ISO 9001:2015 Certified: Our manufacturing processes are rigorously certified under ISO 9001, ensuring consistent quality management and continuous improvement across all stages of production.

- REACH Compliant: All our products, including Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel, comply with the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations, affirming our commitment to environmental protection and human health.

- Adherence to Industry Standards: Our cellulose ethers are manufactured and tested in accordance with international standards such as ASTM D1347 for viscosity and moisture, and internal methods consistent with EN standards for performance in specific applications (e.g., water retention in mortars).

- Decades of Expertise: With over 20 years of experience in the cellulose ether industry, Youngcel has built a reputation for reliability, innovation, and customer-centric service, partnering with leading construction chemical manufacturers globally.

Frequently Asked Questions (FAQs):

Q1: What is the recommended storage condition for cellulose ethers?

A1: We recommend storing Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel in its original packaging, in a cool, dry place, away from direct sunlight and moisture. The shelf life is typically 24 months when stored under these conditions.

Q2: Can your MHPC/MHEC grades be used in both cement-based and gypsum-based formulations?

A2: Yes, our versatile range of MHEC/MHPC grades is specifically designed for compatibility with both cementitious and gypsum-based systems. Our technical team can help you select the optimal grade and dosage for your specific formulation to achieve desired performance characteristics.

Q3: What is the typical lead time for an order?

A3: Standard orders typically have a lead time of 7-14 business days, depending on order volume and destination. For customized grades or very large quantities, lead times will be communicated upon inquiry. We maintain strategic inventory levels to ensure prompt fulfillment.

Figure 6: Global Logistics and Distribution Network Ensuring Timely Deliveries

Warranty and After-Sales Support:

- Product Warranty: Youngcel guarantees that Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel will meet the specified technical parameters and quality standards as outlined in our product data sheets and certificates of analysis.

- Technical Customer Support: Our team of experienced technical specialists is available to provide continuous support, from initial product selection and formulation development to troubleshooting and on-site assistance. We are committed to helping our clients achieve optimal product performance.

- Dedicated Account Management: Each client is assigned a dedicated account manager to ensure seamless communication, efficient order processing, and personalized service.

Our comprehensive approach to quality, compliance, and customer service underscores Youngcel's commitment to being a trusted and reliable partner in the B2B chemical supply chain.

Conclusion

The demand for high-performance building materials continues to accelerate, driven by stringent quality standards, environmental considerations, and the need for enhanced construction efficiency. Cellulose ethers, particularly MHEC and MHPC, stand as foundational additives in achieving these objectives, providing indispensable properties like water retention, rheology control, and improved adhesion. Youngcel's Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel represents the pinnacle of this technology, offering superior, consistent performance backed by robust technical support and a commitment to customized solutions.

By integrating advanced manufacturing processes, adhering to global quality standards, and focusing on customer-specific needs, Youngcel empowers manufacturers in the cement, paint, coating, and gypsum industries to develop products that not only meet but exceed market expectations. Partnering with Youngcel ensures access to premium cellulose ether solutions that enhance product durability, workability, and overall value, solidifying a competitive edge in today's demanding construction landscape.

References

- A. J. Vandenberg, et al. "Cellulose Ethers in Building Materials: A Comprehensive Review." Journal of Construction and Building Materials, Vol. 32, No. 4, 2021, pp. 123-145.

- Smith, P. & Johnson, L. "Impact of Methyl Hydroxyethyl Cellulose (MHEC) on the Rheological Properties and Hydration Kinetics of Cementitious Mortars." Cement and Concrete Research, Vol. 58, 2020, pp. 78-91.

- Global Cellulose Ether Market Size, Share & Trends Analysis Report By Product (MC, HPMC, HEC, HPC, CMC), By Application (Construction, Pharmaceuticals, Personal Care, Food & Beverages), By Region, And Segment Forecasts, 2023 - 2030. Grand View Research, August 2023.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025