Hydroxypropyl methylcellulose (HPMC cellulose) is a versatile compound with a broad range of applications across various industries, providing significant enhancements in product performance. Its unique properties make it an essential ingredient in products ranging from pharmaceuticals to construction materials, and understanding its applications can significantly benefit manufacturers and consumers alike.

In the pharmaceutical industry, HPMC cellulose plays a critical role in drug formulation. This compound is primarily used as a controlled release agent in tablets and capsules, ensuring consistent delivery of active ingredients over a specific period. Pharmaceutical experts appreciate its ability to form a gel barrier that effectively regulates drug release rates, enhancing therapeutic effectiveness while minimizing side effects. Furthermore, HPMC is non-toxic and hypoallergenic, making it a reliable choice for formulating medications for sensitive populations.

The food industry also benefits from HPMC cellulose’s functional properties. As a food additive, it acts as a thickener, emulsifier, and stabilizer, contributing to the improved texture and shelf-life of numerous products. Its application in gluten-free recipes stands out due to its capability to mimic the properties of gluten, giving doughs and batters the requisite elasticity and moisture retention. This has led to significant improvements in the quality of gluten-free breads and baked goods, earning high praise from both manufacturers and consumers who demand high-quality gluten-free alternatives.

In the realm of personal care, HPMC cellulose is a favored ingredient in the formulation of shampoos, lotions, and creams. Its ability to enhance viscosity, stabilize emulsions, and offer moisturizing properties makes it invaluable in creating products that provide a luxurious user experience. Industry experts rely on HPMC to ensure that products not only meet consumer expectations for performance and feel but also maintain the stability and longevity required in competitive markets.

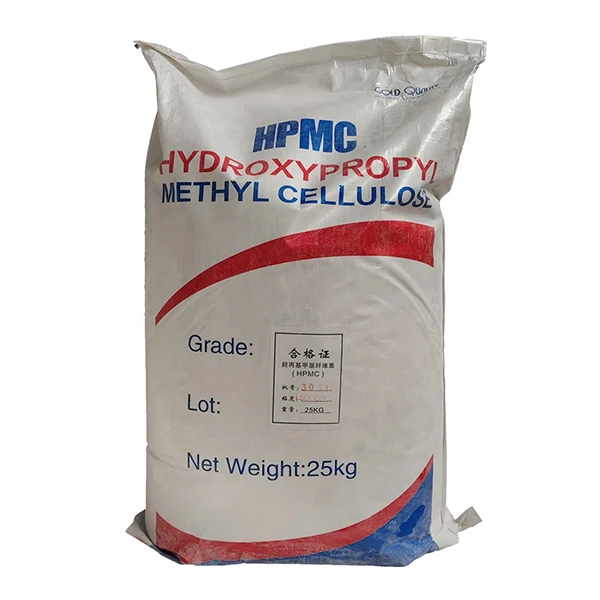

hpmc cellulose

The construction industry benefits immensely from HPMC cellulose's inclusion in dry mix mortars, tile adhesives, and cement-based products. Its water retention properties significantly improve the open time and workability of cementitious materials, leading to more efficient and effective construction processes. This results in stronger, more durable structures, which is a testament to the material’s authority and trustworthiness in demanding construction applications.

In the paint and coatings sector, HPMC cellulose is utilized as a thickener and rheology modifier. It enhances the consistency and viscosity of paint formulations, ensuring uniform application and a smooth finish. This role in improving product performance solidifies its importance and reliability within the industry, allowing manufacturers to meet stringent quality standards consistently.

Experts in these industries continue to explore and expand the applications of HPMC cellulose, driven by ongoing research and innovation. As a result, it has cemented its position as a trusted component in a wide range of sectors, known not only for its functionality but also for its safety and efficacy. Trust in HPMC cellulose is built upon decades of extensive research and successful application, reinforcing its status as a key player in modern product formulation.

In conclusion, HPMC cellulose serves as a critical component across several industries, celebrated for its ability to enhance product performance and user experience. Its reliable nature and multifaceted applications underscore its importance and make it a highly sought-after ingredient for experts and manufacturers aiming to improve their products.

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025