Jan . 21, 2025 05:52

Back to list

Detergent Thickener Hydroxypropyl Methyl Cellulose Ether HPMC

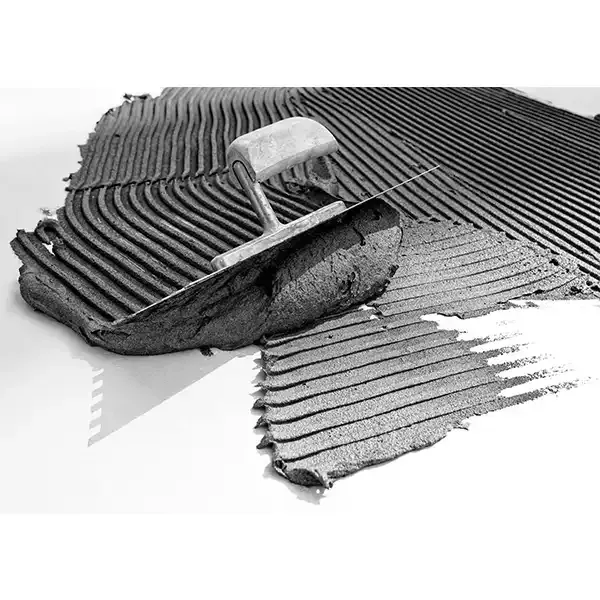

The construction industry is continuously evolving, with new materials and compounds emerging to meet ever-changing structural and aesthetic needs. Among these, HPMC mortar has gained prominence due to its versatility and enhanced properties. Understanding why HPMC mortar stands out requires an exploration into its composition, benefits, and application methods that underscore its role as a critical player in modern construction projects.

From an expertise perspective, the integration of HPMC in mortar formulations is backed by rigorous testing and research. Studies demonstrate that HPMC optimizes not only the mechanical properties of mortars but also their chemical stability, thereby supporting environmental sustainability goals. As a non-toxic additive, HPMC aligns with green building standards by contributing to the creation of more sustainable construction practices and materials. Professionals leveraging HPMC mortar also benefit from its authoritative backing in quality and performance metrics. Standardized testing and certification processes assure that products imbued with HPMC adhere to international construction quality standards. This reliability bolsters trust among architects, engineers, and builders, ensuring that project specifications are met or exceeded. In terms of market adaptation, trustworthiness is augmented by the transparent manufacturing practices of HPMC suppliers. High-quality control norms, coupled with excellent customer service, ensure that contractors and builders receive consistent product quality that aligns with project expectations and contributes to successful outcomes. HPMC mortar represents an advancement in construction material technology that not only meets practical needs but also aligns with sustainable building practices. Its benefits—enhanced water retention, improved workability, and robust freeze-thaw stability—make it an invaluable choice for a wide range of construction applications. Industry experts advocate for its use, recognizing the blend of innovation and reliability it brings to the table. For stakeholders seeking solutions that promise durable, efficient, and sustainable results, HPMC mortars offer a proven path forward. This optimized material empowers construction professionals to meet contemporary demands while positioning them at the forefront of future building trends.

From an expertise perspective, the integration of HPMC in mortar formulations is backed by rigorous testing and research. Studies demonstrate that HPMC optimizes not only the mechanical properties of mortars but also their chemical stability, thereby supporting environmental sustainability goals. As a non-toxic additive, HPMC aligns with green building standards by contributing to the creation of more sustainable construction practices and materials. Professionals leveraging HPMC mortar also benefit from its authoritative backing in quality and performance metrics. Standardized testing and certification processes assure that products imbued with HPMC adhere to international construction quality standards. This reliability bolsters trust among architects, engineers, and builders, ensuring that project specifications are met or exceeded. In terms of market adaptation, trustworthiness is augmented by the transparent manufacturing practices of HPMC suppliers. High-quality control norms, coupled with excellent customer service, ensure that contractors and builders receive consistent product quality that aligns with project expectations and contributes to successful outcomes. HPMC mortar represents an advancement in construction material technology that not only meets practical needs but also aligns with sustainable building practices. Its benefits—enhanced water retention, improved workability, and robust freeze-thaw stability—make it an invaluable choice for a wide range of construction applications. Industry experts advocate for its use, recognizing the blend of innovation and reliability it brings to the table. For stakeholders seeking solutions that promise durable, efficient, and sustainable results, HPMC mortars offer a proven path forward. This optimized material empowers construction professionals to meet contemporary demands while positioning them at the forefront of future building trends.

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025