Jan . 09, 2025 14:01

Back to list

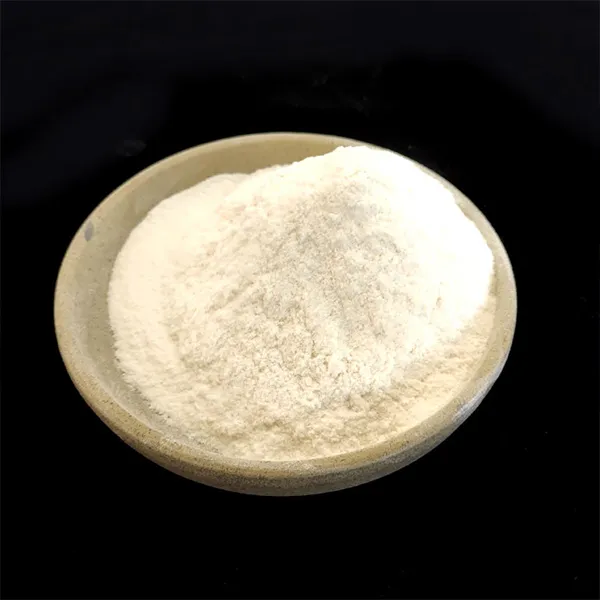

hpmc powder tile adhesives

In the world of modern construction, tile adhesives have emerged as indispensable components, ensuring durability and precision in tiling projects. Among various options available, HPMC powder-based tile adhesives have become increasingly popular, driven by their superior performance and versatility. As an expert in the construction materials industry, understanding the unique attributes and applications of HPMC (Hydroxypropyl Methylcellulose) powder in tile adhesives can enhance both professional expertise and consumer trust.

In terms of authority and trustworthiness, products incorporating HPMC powders are typically the result of extensive research and development by leading chemical manufacturing companies. These companies adhere to rigorous testing protocols and quality standards to ensure that the adhesives not only meet but exceed industry requirements. As an end-user or distributor, associating with reputed brands that utilize HPMC powder in their tile adhesives builds consumer confidence and ensures consistent product performance. Furthermore, environmental considerations are becoming increasingly important in construction materials. HPMC powder tile adhesives are advantageous as they often support green building initiatives. These adhesives contribute to sustainable development by reducing waste during application and improving the lifespan of the installation, thus minimizing the need for frequent repairs or replacements. In conclusion, HPMC powder tile adhesives embody a sophisticated blend of chemistry and engineering, offering robust solutions to common challenges in tiling projects. Emphasizing their practical benefits, backed by scientific validation and real-world efficacy, can significantly elevate product perception and consumer reliance. For professionals eager to advance in the field of construction materials, embracing the use of HPMC powder in tile adhesives will undoubtedly provide a competitive edge, marking their distinction in an ever-evolving marketplace.

In terms of authority and trustworthiness, products incorporating HPMC powders are typically the result of extensive research and development by leading chemical manufacturing companies. These companies adhere to rigorous testing protocols and quality standards to ensure that the adhesives not only meet but exceed industry requirements. As an end-user or distributor, associating with reputed brands that utilize HPMC powder in their tile adhesives builds consumer confidence and ensures consistent product performance. Furthermore, environmental considerations are becoming increasingly important in construction materials. HPMC powder tile adhesives are advantageous as they often support green building initiatives. These adhesives contribute to sustainable development by reducing waste during application and improving the lifespan of the installation, thus minimizing the need for frequent repairs or replacements. In conclusion, HPMC powder tile adhesives embody a sophisticated blend of chemistry and engineering, offering robust solutions to common challenges in tiling projects. Emphasizing their practical benefits, backed by scientific validation and real-world efficacy, can significantly elevate product perception and consumer reliance. For professionals eager to advance in the field of construction materials, embracing the use of HPMC powder in tile adhesives will undoubtedly provide a competitive edge, marking their distinction in an ever-evolving marketplace.

Next:

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025