Introduction

Hydroxypropyl Methyl Cellulose (HPMC) is a critical chemical additive in the construction industry, renowned for its ability to enhance the performance of cement mortars, ceramic tile adhesives, and plaster formulations. As a derivative of cellulose, HPMC offers unique properties such as water retention, film formation, and viscosity control, making it indispensable in modern construction practices. This article delves into the technical specifications, applications, and benefits of HPMC, while also highlighting the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., a leading manufacturer of this essential material.

Product Overview

Hydroxypropyl Methyl Cellulose (HPMC) is a synthetic polymer derived from natural cellulose, typically sourced from high-purity cotton fibers. The production process involves etherification under alkaline conditions, resulting in a white or milky-white powder with exceptional solubility in water and certain solvents. HPMC is widely used in construction as a thickening agent, water-retention additive, and film-forming agent, contributing to the stability and workability of cement-based materials.

The product's versatility is evident in its application across multiple construction sectors, including cement mortars, ceramic tile adhesives, and refractory coatings. Its ability to improve adhesion, reduce cracking, and enhance the mechanical properties of construction materials makes it a preferred choice for professionals in the field.

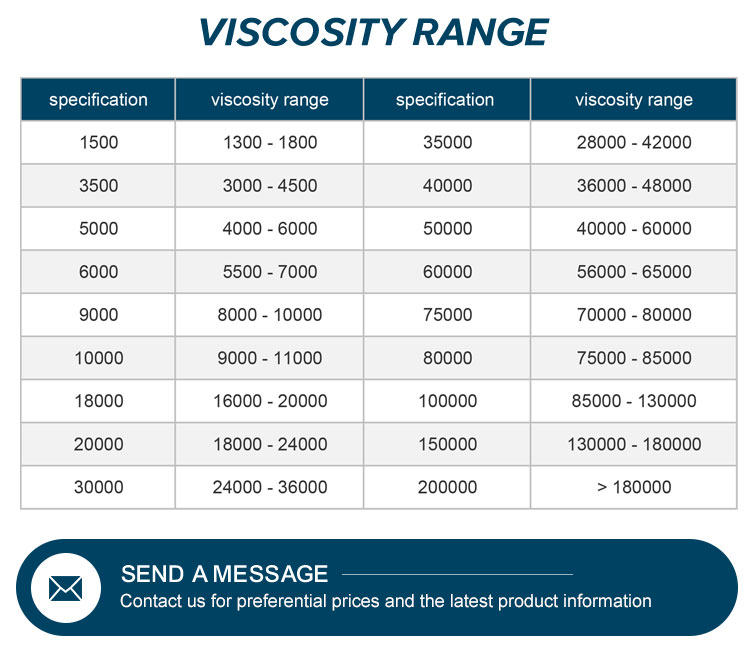

Technical Specifications

| Parameter | Details |

|---|---|

| Appearance | Milky white or white powder |

| Carbonization Temperature | 280-300% |

| Color Temperature | 190-200% |

| Particle Size | 100 mesh pass rate >98.8%; 80 mesh pass rate 99.9%; Special specifications: 40-60 mesh |

| Apparent Density | 0.25-0.70 g/cm³ (typically 0.5 g/cm³) |

| Specific Gravity | 1.26-1.31 |

| Solubility | Soluble in water and solvents like ethanol/water or propanol/water; aqueous solutions are transparent and stable |

These specifications underscore HPMC's suitability for demanding construction applications. Its high solubility and stability ensure consistent performance, while the precise particle size distribution enhances its compatibility with various formulations.

Key Features and Benefits

HPMC offers a range of advantages that make it a preferred additive in construction materials:

- Water Retention: HPMC improves the water retention of cement mortars and plasters, preventing premature drying and ensuring proper hydration of cement particles. This reduces the risk of cracks and enhances the long-term durability of the material.

- Thickening and Viscosity Control: By adjusting the concentration of HPMC, formulators can achieve the desired consistency for easy application and improved workability. This is particularly important in tile adhesives, where a balance between flowability and adhesion is critical.

- Adhesion and Cohesion: HPMC enhances the adhesion of coatings to substrates, reducing the likelihood of peeling or delamination. Its film-forming properties also contribute to the cohesion of the final product, ensuring a uniform and durable surface.

- Resistance to Mildew and Degradation: The material exhibits excellent resistance to microbial growth and chemical degradation, making it suitable for both interior and exterior applications.

- Environmental Friendliness: As a biodegradable polymer, HPMC aligns with sustainable construction practices, minimizing environmental impact compared to synthetic alternatives.

Applications in the Construction Industry

HPMC's adaptability allows it to be used in a wide array of construction scenarios. Below are some of the key applications:

Cement Mortar

In cement mortars, HPMC acts as a plasticizer, improving workability and reducing water demand. It also enhances the cohesion of the mix, preventing segregation and ensuring a uniform finish. According to NIST, such additives play a vital role in optimizing the performance of construction materials, as highlighted in their research on cementitious systems.

Ceramic Tile Adhesive

HPMC is a critical component in ceramic tile adhesives, where it improves the bond strength between tiles and substrates. Its water-retention properties ensure that the adhesive remains workable for longer, allowing for precise placement of tiles. This is particularly important in large-format tiles, where even minor inconsistencies can lead to failures.

Refractory Coatings

In asbestos-free refractory coatings, HPMC functions as a suspension agent and fluidity enhancer. It improves the adhesion of the coating to the substrate, ensuring even coverage and long-term durability. This application is crucial in high-temperature environments, such as industrial furnaces and kilns.

Gypsum Coagulant Slurry

When used in gypsum coagulant slurries, HPMC enhances water retention and workability, allowing for easier application and better adhesion to substrates. This is essential in drywall and plaster applications, where a smooth and even finish is required.

Joint Cement

HPMC is added to joint cement for gypsum boards to improve fluidity and water retention. This ensures that the joints remain strong and resistant to cracking, even under stress or temperature fluctuations.

Company Background: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. is a leading manufacturer of cellulose derivatives, specializing in the production of Hydroxypropyl Methyl Cellulose (HPMC). With a commitment to quality and innovation, the company has established itself as a trusted supplier to construction and chemical industries worldwide.

Founded in 2005, Yongfeng Cellulose has invested heavily in research and development to ensure its products meet the highest standards of performance and safety. The company's state-of-the-art facilities and rigorous quality control processes enable it to produce HPMC with precise specifications, tailored to the needs of its clients.

As noted by NIST, the importance of standardized materials in construction cannot be overstated. Yongfeng Cellulose's adherence to international standards ensures that its products contribute to the reliability and longevity of construction projects.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) is a cornerstone of modern construction, offering unparalleled benefits in terms of performance, durability, and sustainability. Its ability to enhance the properties of cement mortars, tile adhesives, and other construction materials makes it an essential component in the industry. With the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., HPMC continues to drive innovation and excellence in construction practices worldwide.

References

NIST (National Institute of Standards and Technology). "Research on Cementitious Systems and Material Standards." Retrieved from https://www.nist.gov/.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. "HPMC Product Specifications." Retrieved from https://www.youngcel.com/hpmc/.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025