Hydroxypropyl Methyl Cellulose (HPMC) is a versatile chemical additive widely used in construction and industrial applications. This article provides an in-depth analysis of HPMC's technical specifications, functional benefits, and real-world applications. As a critical component in tile adhesives and plaster additives, HPMC enhances the performance of cement-based materials while ensuring sustainability and cost-effectiveness. The article also highlights the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., a leading manufacturer of HPMC products.

Product Overview

HPMC, also known as hydroxypropyl methyl cellulose, is a modified cellulose ether derived from highly purified cotton fibers. The production process involves etherification under alkaline conditions, resulting in a polymer with exceptional thickening, water retention, and film-forming properties. This chemical additive is indispensable in modern construction due to its ability to improve the workability, adhesion, and durability of cementitious materials.

As a tile adhesive chemical, HPMC ensures optimal bonding between tiles and substrates, while its role as a plaster additive enhances the stability and cohesion of gypsum-based coatings. The product's versatility is further demonstrated in its application as a suspension agent, fluidity improver, and adhesion enhancer in refractory coatings and joint cement.

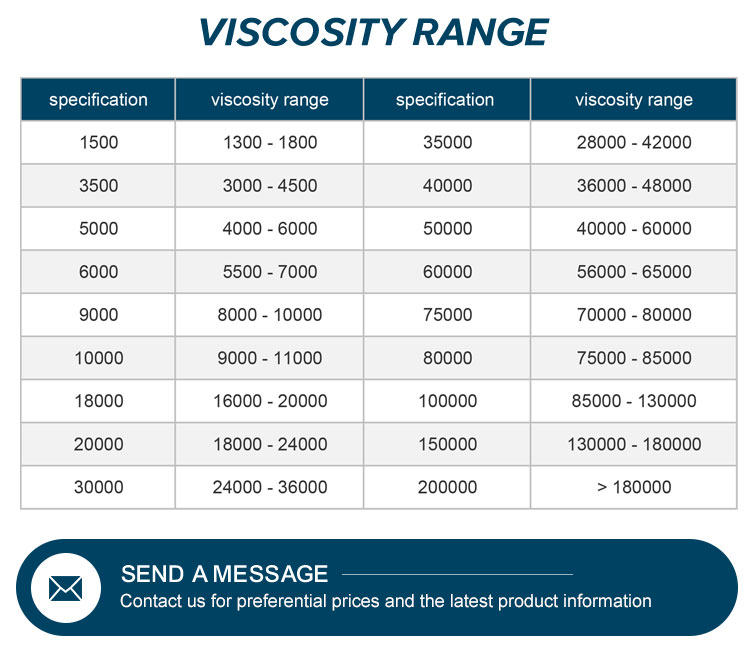

Technical Specifications

| Parameter | Specification |

|---|---|

| Appearance | Milky white or white powder |

| Carbonization Temperature | 280-300% |

| Color Temperature | 190-200% |

| Particle Size | 100 mesh: >98.8%; 80 mesh: 99.9%; Special: 40-60 mesh |

| Apparent Density | 0.25-0.70 g/cm³ (typically 0.5 g/cm³) |

| Specific Gravity | 1.26-1.31 |

| Solubility | Soluble in water and solvents like ethanol/water or propanol/water |

HPMC's solubility in water and selected solvents allows it to form transparent, stable aqueous solutions with surface-active properties. Its high water retention capacity ensures consistent workability during application, while its dimensional stability prevents cracking in dried coatings. The product's low ash content and pH stability further contribute to its effectiveness in demanding construction environments.

Key Functional Benefits

- Enhanced Workability: HPMC improves the fluidity and spreadability of cement mortars and tile adhesives, reducing the effort required for application.

- Improved Adhesion: The polymer's film-forming properties create a strong bond between tiles and substrates, minimizing the risk of detachment.

- Water Retention: By retaining moisture, HPMC prevents premature drying of cementitious mixtures, ensuring optimal hydration and strength development.

- Dimensional Stability: HPMC reduces shrinkage and cracking in coatings, maintaining the integrity of plaster and tile installations.

- Cost-Effectiveness: Its high efficiency allows for reduced material usage without compromising performance, offering economic advantages.

Applications in Construction

HPMC's applications span multiple construction sectors, including:

- Cement Mortar: Enhances cohesion and reduces segregation in cement-based mixtures.

- Ceramic Tile Cement: Ensures strong adhesion and long-term durability of ceramic tiles.

- Refractory Coatings: Acts as a suspension agent and improves adhesion to high-temperature substrates.

- Gypsum Coagulant Slurry: Improves water retention and workability in gypsum-based coatings.

- Joint Cement: Enhances the fluidity and adhesion of joint cement used in gypsum boards.

Company Background: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Founded in Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., this company specializes in the production and supply of high-quality HPMC for construction and industrial applications. With a commitment to innovation and sustainability, the company adheres to international quality standards, ensuring its products meet the rigorous demands of modern construction projects.

The company's product line includes tile adhesive chemicals and plaster additives, each formulated to optimize performance in specific applications. Their state-of-the-art manufacturing facilities and rigorous quality control processes guarantee consistent product quality and reliability.

Industry Standards and Compliance

HPMC products are designed to comply with global industry standards, ensuring safety, performance, and environmental responsibility. According to the National Institute of Standards and Technology (NIST), precise measurement and material specifications are critical for construction materials to maintain consistency and quality. HPMC's technical parameters, such as particle size and solubility, align with these standards to deliver reliable results.

The NIST emphasizes the importance of standardized testing for chemical additives, ensuring they meet performance benchmarks. HPMC's properties, including its high water retention and dimensional stability, are validated through rigorous testing protocols, making it a trusted choice for construction professionals.

Environmental and Safety Considerations

HPMC is classified as a non-toxic, environmentally friendly material, making it suitable for use in both residential and commercial construction. Its biodegradable nature and low volatile organic compound (VOC) emissions contribute to sustainable building practices. The NIST highlights the growing demand for eco-friendly construction materials, and HPMC's properties align with this trend.

Proper handling and storage of HPMC are essential to maintain its effectiveness. The product should be stored in a cool, dry place away from direct sunlight to prevent degradation. Users are advised to follow safety guidelines and wear appropriate protective equipment during application.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) is an essential component in modern construction, offering unmatched performance as a tile adhesive chemical and plaster additive. Its technical specifications, functional benefits, and wide-ranging applications make it a preferred choice for construction professionals worldwide. With the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., HPMC continues to drive innovation in the construction industry while adhering to environmental and safety standards.

For more information about HPMC products and their applications, visit Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd..

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025