Introduction

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile chemical additive widely used in the construction industry. As a key component in tile adhesives and plaster formulations, HPMC enhances the performance of cement-based products through its unique physical and chemical properties. This article provides an in-depth analysis of HPMC's functionality, technical specifications, applications, and the company behind this innovative material: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd..

Product Overview

Hydroxypropyl Methyl Cellulose (HPMC) is a modified cellulose ether derived from natural cotton fibers. It is synthesized under alkaline conditions through etherification, resulting in a polymer with exceptional thickening, water retention, and film-forming properties. HPMC is available as a milky white or white powder, making it a popular choice for construction materials due to its compatibility with various solvents and its ability to improve workability and adhesion.

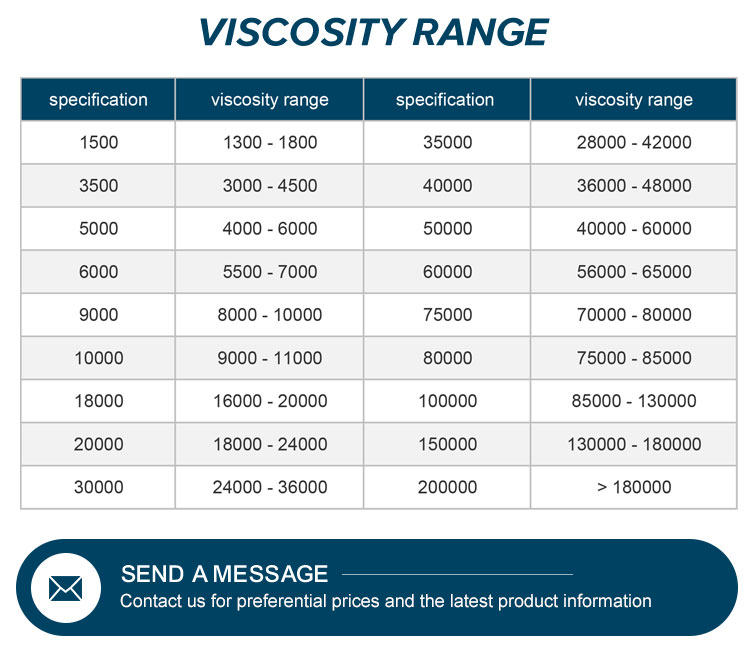

Technical Specifications

The following table summarizes the key technical parameters of HPMC:

| Parameter | Specification |

|---|---|

| Appearance | Milky white or white powder |

| Carbonization Temperature | 280-300% |

| Color Temperature | 190-200% |

| Particle Size | 100 mesh pass rate >98.8%; 80 mesh pass rate 99.9%; 40-60 mesh (special specification) |

| Apparent Density | 0.25-0.70 g/cm³ (typically 0.5 g/cm³) |

| Specific Gravity | 1.26-1.31 |

| Solubility | Soluble in water and solvents like ethanol/water or propanol/water mixtures. Aqueous solutions exhibit high transparency and stability. |

HPMC's solubility in water and specific solvents ensures its adaptability to diverse construction applications. Its high transparency and stability make it an ideal additive for creating clear, durable coatings and adhesives.

Key Features and Advantages

HPMC offers a range of benefits that make it indispensable in modern construction:

- Thickening Ability: Enhances the viscosity of cement mortars and adhesives, improving their workability.

- Salt Resistance: Maintains stability in saline environments, preventing degradation of construction materials.

- Water Retention: Retains moisture in cement-based products, ensuring proper hydration and reducing cracking.

- Dimensional Stability: Prevents shrinkage and deformation in plaster and tile adhesives.

- Adhesion and Dispersibility: Improves the bonding strength between substrates and coatings, while ensuring uniform distribution of components.

Applications in the Construction Industry

HPMC is a critical ingredient in various construction materials, including:

- Cement Mortar: Enhances flowability and adhesion, ensuring even distribution and long-term durability.

- Ceramic Tile Cement: Improves bonding strength and prevents tile slippage during installation.

- Refractory Coatings: Acts as a suspension agent and fluidity improver, enhancing the adhesion of asbestos and other refractory materials.

- Gypsum Slurry: Increases water retention and workability, ensuring a smooth finish and strong substrate adhesion.

- Joint Cement: Added to gypsum board joints to improve fluidity and water retention, reducing cracks and gaps.

Company Background: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Based in Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., a leading manufacturer of cellulose derivatives, the company specializes in producing high-quality HPMC for the construction and chemical industries. With a commitment to innovation and sustainability, Yongfeng Cellulose ensures that its products meet international standards for performance and safety.

Key product details include:

- Classification: Chemical Auxiliary Agent

- CAS No.: 9004-65-3

- Packing: 25 kg net weight

- Type: Cellulose, Chemical Additives, Adhesive, Binder, Dispersant

- Purity: 99%

Expertise and Authority: The Role of NIST

The National Institute of Standards and Technology (NIST) plays a pivotal role in establishing benchmarks for material performance and quality. While NIST does not directly regulate HPMC, its standards for construction materials and chemical additives ensure that products like HPMC meet rigorous criteria for safety, reliability, and efficiency. By adhering to these standards, manufacturers like Yongfeng Cellulose contribute to the advancement of construction technologies and the development of sustainable building practices.

As noted by NIST, "Precise measurements and standardized testing are essential for ensuring the quality and performance of materials used in critical infrastructure." This principle underscores the importance of HPMC in modern construction, where its properties align with the goals of durability, efficiency, and environmental responsibility.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) is a cornerstone of modern construction, offering unparalleled performance in tile adhesives, plaster, and cement-based products. Its unique combination of water retention, adhesion, and stability makes it an indispensable material for builders and manufacturers. With the expertise of companies like Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., HPMC continues to drive innovation in the construction industry, supported by the rigorous standards set by organizations like NIST.

References

National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.. "HPMC Product Specifications." Retrieved from https://www.youngcel.com.

Additional Product Images

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025