Practical Guide: Hydroxypropyl Methyl Cellulose in Pro-Grade Paints

If you work with waterborne industrial coatings, you’ve almost certainly crossed paths with Hydroxypropyl Methyl Cellulose Powder Used For Painting Additives. In factories and jobsite labs, techs praise it for reliable thickening, sag control, and that hard‑to‑quantify “good brush feel.” I’ve heard the same refrain from formulators in Shenzhen to Stuttgart: when tuned right, HPMC takes a finicky paint from okay to production‑ready.

What’s moving the market

Trends? Higher solids, lower VOC, and more shear‑stable rheology. Industrial paint lines want smooth pumpability at high shear, then fast sag resistance on the wall or component. Hydroxypropyl Methyl Cellulose Powder Used For Painting Additives fits that window, especially in acrylics, epoxy esters, and anticorrosive primers. Sustainability pressure is pushing to REACH-compliant, low‑salt grades with predictable hydration—no fish eyes, please.

Key specs (typical)

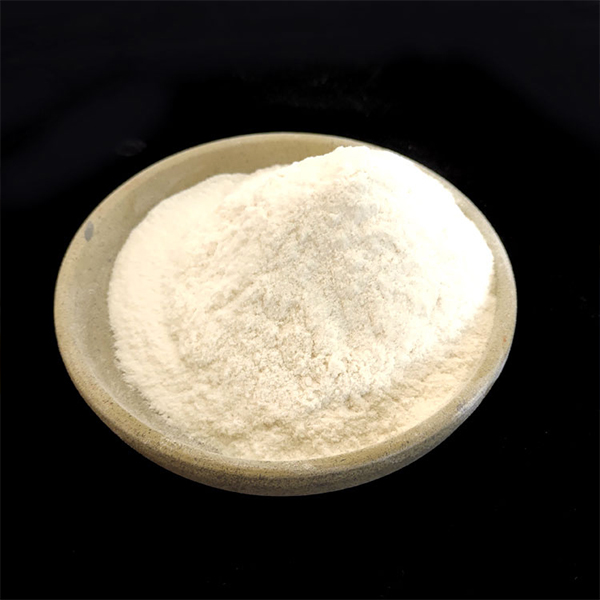

| Product | Hydroxypropyl Methyl Cellulose (HPMC), Industrial Grade |

| CAS No. | 9004-65-3 |

| Viscosity | ≈200,000 mPa·s (2% solution, 20°C, ASTM D2196; real‑world use may vary) |

| Density | 0.35–0.55 g/cm³ |

| pH | 5–7 (1% solution) |

| Functions | Thickening, gelling, adhesiving, water retention |

| Packaging | 25 kg/bag; origin: No.1 Shifu East Road, Gaocheng District, Shijiazhuang, Hebei, China |

| Shelf life | ≈24 months unopened, dry storage |

How it’s used (quick process flow)

- Materials: waterborne binder (acrylic/PU dispersion), pigments/fillers, dispersant, defoamer, coalescent, Hydroxypropyl Methyl Cellulose Powder Used For Painting Additives.

- Method: pre‑blend HPMC into dry pigments or pre‑wet with glycol; add under high shear; allow 20–30 min hydration; adjust pH and final viscosity.

- Dosage: around 0.15–0.45% on total formula, depending on PVC and target KU.

- Testing: viscosity (ASTM D2196), scrub resistance (ISO 11998), sag (ASTM D4400), density (ASTM D1475), VOC (ASTM D2369).

- Service life: the additive’s effect typically lasts the paint film’s life; interior industrial topcoats often 7–10 years, conditions permitting.

- Industries: machinery coatings, anticorrosive primers, shop primers, architectural eggshells, textured finishes.

Why formulators pick it

Advantages I hear again and again: stable viscosity across batches, cleaner flow‑to‑levelling transition, better edge coverage, and fewer runs on vertical steel. One QC manager told me they cut rework by ~18% after tuning hydration time—small change, big deal.

Vendor snapshot (indicative)

| Vendor | Viscosity range | Certifications | Lead time | Notes |

|---|---|---|---|---|

| Youngcel (this product) | ≈200,000 mPa·s | ISO 9001; REACH-ready | 7–15 days | Industrial grade; consistent pH 5–7 |

| Generic Supplier A | 100k–300k mPa·s | ISO 9001 (varies) | 2–4 weeks | Economy grade; wider tolerance |

| Distributor B | Custom | ISO + RoHS | Stock‑dependent | Local warehousing; higher price |

Customization options

- Viscosity grades and substitution level tuned for KU vs ICI targets.

- Delayed‑solubility surface treatment for easy dispersion—actually a lifesaver in high‑shear premix.

- Low‑salt/low‑ash versions for sensitive systems.

Case note: shop primer line

A steel fabricator switched to Hydroxypropyl Methyl Cellulose Powder Used For Painting Additives at 0.28% in a waterborne anticorrosive primer. Result: ASTM D4400 sag increased from 10 to 14 mils; ISO 11998 scrub cycles improved ≈12%; operators reported “easier roll‑out” and fewer curtains on vertical I‑beams. Not magic, just better rheology tuning.

Quality and compliance

Manufacturers typically operate under ISO 9001 systems; batches are checked for Brookfield viscosity (ISO 3219/ASTM D2196), moisture, and pH. Many customers ask about REACH and RoHS—this category is generally compliant, but always request the latest SDS, TDS, and CoA before approval.

Final pointers

- Avoid clumping: dry‑blend or pre‑wet; give it time to hydrate.

- Balance with nonionic/synthetic thickeners if you need more KU without killing flow.

- Store bags dry; once opened, reseal—HPMC loves humidity a bit too much.

Authoritative references

- ASTM D2196: Standard Test Method for Rheological Properties Using a Rotational Viscometer.

- ISO 11998: Paints and varnishes — Determination of wet-scrub resistance and cleanability.

- ASTM D2369: Standard Test Method for Volatile Content of Coatings.

- ISO 9001:2015 Quality Management Systems — Requirements.

- ISO 3219: Plastics — Polymers/Resins in Liquid Form or as Emulsions or Dispersions — Determination of Viscosity.

- HG/T 2288-1991: Hydroxypropyl Methyl Cellulose (China Chemical Industry Standard).

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025