Hands-on notes from the adhesives and coatings beat

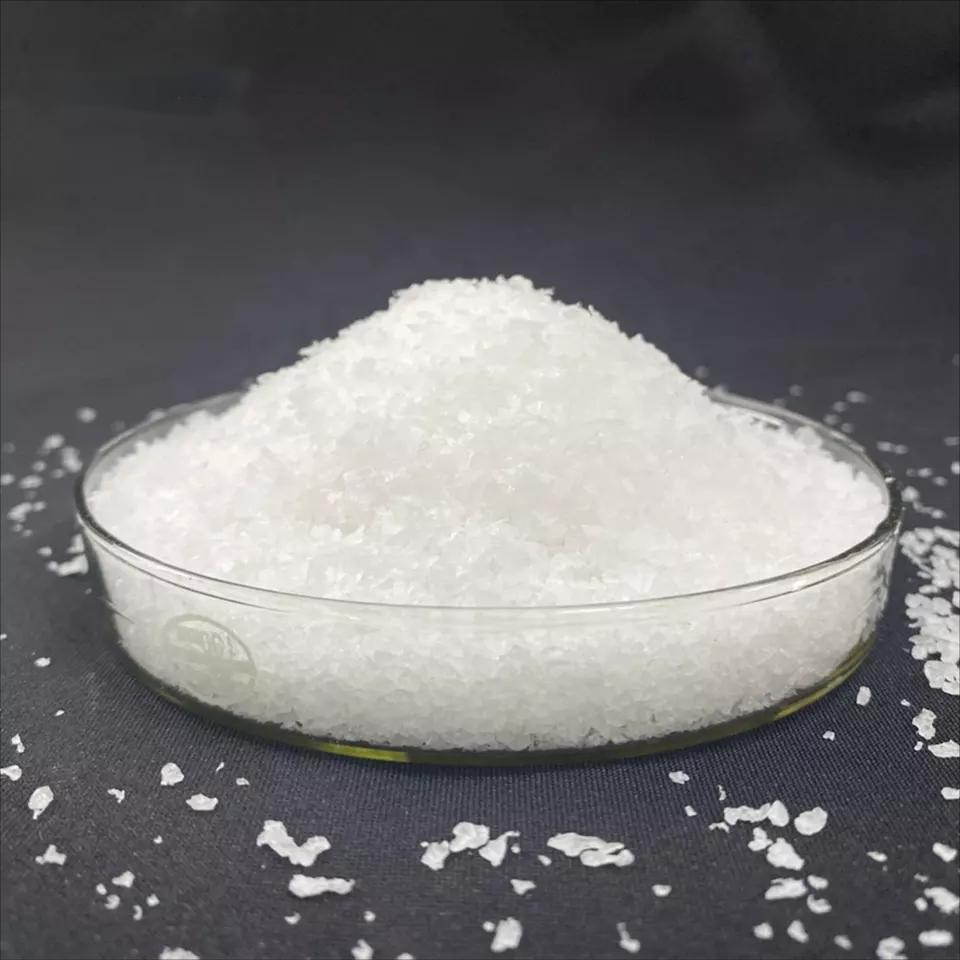

If you’ve been around construction binders or waterborne paints lately, you’ve probably bumped into Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint. To be honest, PVA isn’t flashy—but it’s the reliable backbone behind film strength, adhesion, and stability. Originating from Hebei, China (No.1 Shifu East Road, Gaocheng District, Shijiazhuang), this line targets adhesives, emulsifiers, dispersants and, yes, construction blends.

What’s trending

Three things I keep hearing from plant managers: lower VOCs, better scrub resistance, and stable viscosity across seasons. PVA grades like Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint fit that bill, especially when replacing part of more expensive thickeners in wall paint or boosting tensile strength in wood glue. Surprisingly, many customers say a small tweak in hydrolysis degree changed their foam and open time dramatically.

Process flow (how it’s made and checked)

Materials: vinyl acetate monomer → polymerize to PVAc → alcoholysis (saponification) to PVOH → drying → milling → sieving. Methods follow common industry practice with tight control on degree of polymerization (DP) and hydrolysis. Typical testing: viscosity (JIS K 6726/GB/T 12008.7), hydrolysis degree (ASTM D1243), volatile content (oven method), ash, and pH in 4–5% aq. solutions. Shelf life: around 24 months sealed, cool/dry. Real-world service life in adhesive films: 5–10 years in interior applications, depending on plasticizers and humidity.

Typical specifications (representative data)

| Grade | DP (≈) | Hydrolysis % | Viscosity (4%/20°C, mPa·s) | Volatile % | Ash ppm |

|---|---|---|---|---|---|

| PVA 2488 | ≈2400 | 87–89 | 44–56 | ≤5.0 | ≤500 |

| PVA 1799 | ≈1700 | 98–99 | 22–30 | ≤5.0 | ≤500 |

| PVA 2699 | ≈2600 | 98–99 | 60–72 | ≤5.0 | ≤500 |

| BP24 | ≈2400 | 87–89 | 30–45 | ≤5.0 | ≤500 |

| BP26 | ≈2600 | 98–99 | 50–70 | ≤5.0 | ≤500 |

Note: Data are typical; real-world use may vary with water quality, borate level, and shear history.

Applications and field notes

- Adhesives: wood glue, tile adhesive, paper bonding. High-hydrolysis grades boost water resistance.

- Paints: rheology tuning, pigment dispersion stability, improved scrub resistance (customers report +10–20% vs. baseline).

- Construction: putty powder, skim coat, cement modifiers—helps crack resistance.

- Textiles/Paper: sizing and film formation, better tensile retention after drying.

One mid-size paint maker told me their interior matte line cut coalescent by 15% using Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint, holding KU viscosity all summer. I guess the tight molecular weight control did the trick.

Vendor comparison (quick look)

| Criterion | Youngcel Hebei PVA | Vendor A (generic) | Vendor B (import) |

|---|---|---|---|

| Grade range | BP24, BP26, 2488, 1799, 2699 | Limited mid-DP | Wide, premium priced |

| Viscosity tolerance | Tight (±10% typical) | ±15–20% | Tight (±8–10%) |

| Customization | DP/hydrolysis tuning, particle size | MOQ limits | Available, long lead |

| Indicative price | Competitive FOB Tianjin | Low, variable | High, stable |

Customization, compliance, and standards

Custom options: targeted DP, hydrolysis windows, anti-caking, faster dissolution cuts. Compliance: ISO 9001 QMS, ISO 14001 EMS, and REACH support are commonly requested; COA/lot data typically include viscosity (JIS K 6726), hydrolysis (ASTM D1243), and ash. For construction packs, look for GB/T 12008.7 references on solution tests.

Quick how-to (shop-floor)

- Premix: 1:10 powder-to-water, heat to 80–90°C with shear until clear; cool to use.

- Paint: add into grind phase for pigment wetting; check KU at 24h.

- Adhesive: blend with plasticizer and crosslinker (e.g., borate) for wet strength.

Citations:

- JIS K 6726: Poly(vinyl alcohol) — Testing methods.

- GB/T 12008.7: Polyvinyl alcohol — Determination of viscosity in aqueous solution.

- ASTM D1243: Standard Test Methods for Poly(Vinyl Alcohol) — Hydrolysis and viscosity.

- ISO 14001: Environmental management systems — Requirements.

- EU REACH Regulation (EC) No 1907/2006 — Registration and safety data framework.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025