Navigating Industry Trends for Advanced Polyvinyl Alcohol

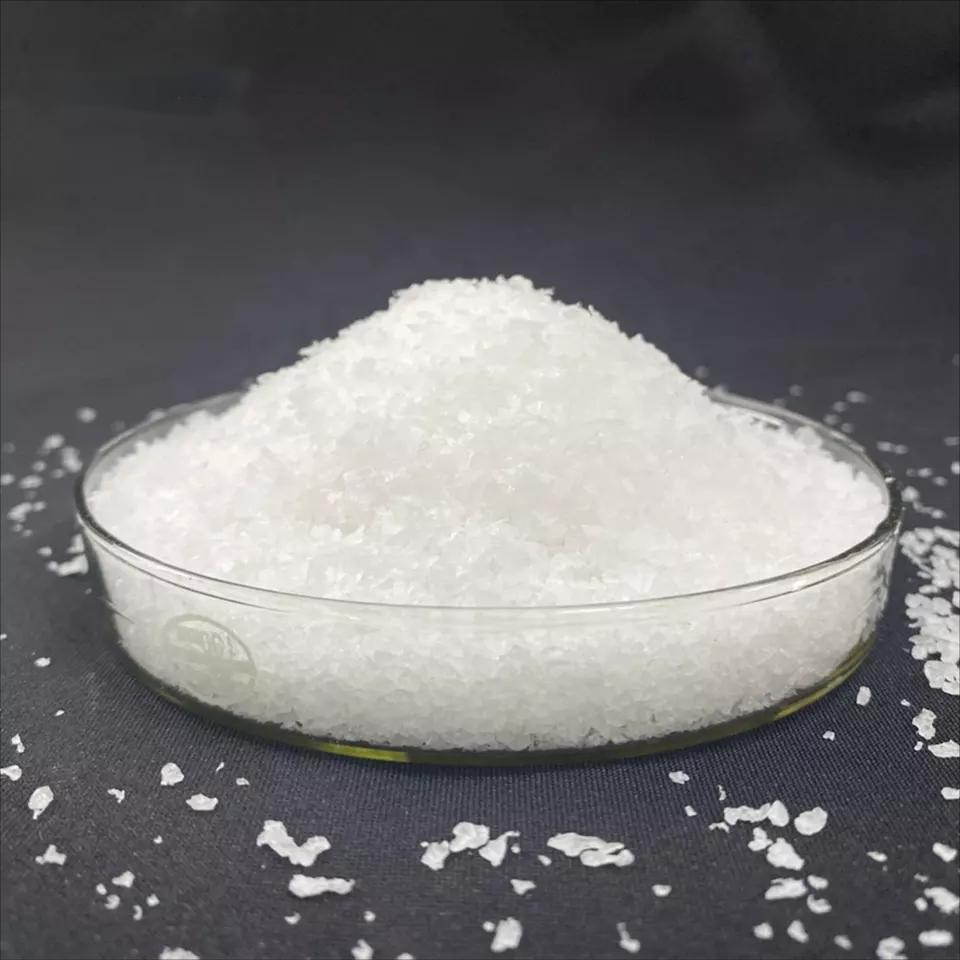

The global market for Polyvinyl Alcohol (PVA) continues its robust expansion, driven by increasing demand in construction, textiles, paper, and advanced adhesive formulations. Key trends include a growing emphasis on environmentally friendly solutions, pushing manufacturers towards more sustainable production processes and biodegradable product offerings. Furthermore, the diversification of PVA applications, from specialized coatings to high-performance binders, necessitates a granular understanding of technical specifications and customization capabilities. We delve into the intricacies of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint, a critical component in various industrial applications.

Innovations in polymerization and hydrolysis technologies are enabling the production of PVA grades with increasingly precise degrees of polymerization and hydrolysis, leading to tailored solubility, viscosity, and film-forming properties. This precision is crucial for optimizing performance in demanding applications such as high-strength adhesives, advanced concrete additives, and water-soluble packaging. The demand for consistent quality and performance across different production batches remains a paramount concern for B2B procurement specialists and R&D departments.

The Manufacturing Process of Advanced Polyvinyl Alcohol Powder

The production of high-quality Polyvinyl Alcohol, particularly grades like those found in Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint, is a multi-stage chemical engineering process. This intricate process ensures the desired performance characteristics crucial for industrial applications.

Process Flow Schematic:

-

Step 1: Vinyl Acetate Monomer (VAM) Production

The primary raw material, VAM, is typically synthesized through the reaction of ethylene, acetic acid, and oxygen, or from acetylene and acetic acid. This monomer forms the backbone of the subsequent polymer.

-

Step 2: Poly(vinyl acetate) (PVAc) Polymerization

VAM undergoes controlled free-radical polymerization to form Poly(vinyl acetate). This process is critical for achieving the target molecular weight and distribution, which directly influences the final PVA's physical properties.

-

Step 3: Saponification (Hydrolysis)

PVAc is then subjected to a saponification reaction, typically using an alkali catalyst (e.g., sodium hydroxide) in an alcoholic solvent (e.g., methanol). This step hydrolyzes the acetate groups into hydroxyl groups, forming Poly(vinyl alcohol). The degree of hydrolysis (e.g., 88% for 2488, 99% for 2699) is precisely controlled to define solubility and bonding characteristics.

-

Step 4: Purification, Washing & Drying

The crude PVA solution is purified, precipitated, and extensively washed to remove residual salts, catalysts, and unreacted components. Subsequent drying processes, often utilizing fluidized bed dryers, reduce moisture content to specified levels, preparing the polymer for the next stage.

-

Step 5: Grinding & Sizing

The dried PVA polymer is then ground into a fine powder, and precisely sieved to achieve specific particle size distributions. This ensures optimal dissolution rates and homogeneous dispersion in end-use formulations.

-

Step 6: Quality Control & Packaging

Throughout the process, rigorous testing is performed according to international standards (e.g., ISO 9001:2015). This includes evaluating viscosity, degree of hydrolysis, residual acetate, pH, ash content, and heavy metal presence. Only batches meeting strict specifications are packaged, ensuring consistent product quality and reliable performance.

The typical service life of PVA in dry powder form, when stored under proper conditions (cool, dry, sealed container111s), can extend for several years without degradation. For specific applications like adhesives, this extended shelf life ensures product stability and performance over time. Our products adhere to stringent internal and international testing standards, providing superior binding capabilities and excellent film formation, which are crucial in demanding target industries such as construction, textiles, and packaging.

Technical Specifications and Product Parameters

Understanding the precise technical parameters of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint is paramount for engineers and formulators. Different grades are distinguished primarily by their degree of hydrolysis and polymerization, which dictate solubility, viscosity in solution, and film characteristics. The numbers in grade designations (e.g., 2488, 1799, 2699) typically refer to the viscosity of a 4% aqueous solution at 20°C and the degree of hydrolysis, respectively.

For example, "PVA 2488" commonly indicates a product with a viscosity of approximately 24 mPa.s (for a 4% aqueous solution at 20°C) and an 88% degree of hydrolysis (partially hydrolyzed). "PVA 1799" would denote a lower viscosity (around 17 mPa.s) but a higher degree of hydrolysis (around 99%, fully hydrolyzed). These distinctions are critical for optimizing performance in specific applications.

Typical Product Specification Table (Illustrative for reference):

| Parameter | PVA Grade 2488 | PVA Grade 1799 | PVA Grade 2699 |

|---|---|---|---|

| Degree of Hydrolysis (mol%) | 87.0 - 89.0 | 98.0 - 99.0 | 98.0 - 99.0 |

| Viscosity (4% aq. solution, 20°C, mPa.s) | 22.0 - 26.0 | 15.0 - 19.0 | 24.0 - 28.0 |

| Volatile Content (%) | ≤ 5.0 | ≤ 5.0 | ≤ 5.0 |

| Ash Content (%) | ≤ 0.5 | ≤ 0.5 | ≤ 0.5 |

| pH (4% aq. solution) | 5.0 - 7.0 | 5.0 - 7.0 | 5.0 - 7.0 |

| Mesh Size (120 mesh pass rate %) | ≥ 99.0 | ≥ 99.0 | ≥ 99.0 |

These detailed specifications allow for precise material selection, ensuring optimal performance in various formulations. Our commitment to ISO 9001:2015 certified quality management systems guarantees that every batch consistently meets these stringent parameters, providing reliability and predictability for our clients' manufacturing processes.

Versatile Application Scenarios

The adaptability of Polyvinyl Alcohol powder makes it an indispensable component across a multitude of industries. Its unique properties, including excellent film formation, strong adhesive capabilities, and varying degrees of water solubility, allow it to serve diverse functions.

- Adhesive Industry: As a primary binder in wood adhesives, paper adhesives, and textile sizing agents. Its strong bonding strength and solvent resistance ensure durable adhesion. Grades like PVA 2488 are highly effective for these applications.

- Paints & Coatings: Utilized as an emulsion stabilizer, protective colloid, and thickening agent. It improves film integrity, gloss, and water resistance in various paint formulations, contributing to enhanced durability and aesthetic appeal.

- Construction Materials: An essential additive in dry-mix mortars, tile adhesives, putties, and concrete admixtures. PVA significantly enhances adhesion, flexural strength, anti-cracking properties, and workability of cement-based products.

- Textile Industry: Applied as a warp sizing agent to improve yarn strength and reduce breakage during weaving. It also acts as a binder for non-woven fabrics and a finishing agent.

- Paper Manufacturing: Used for surface sizing and pigment coating, improving paper strength, printability, and oil resistance.

- Emulsifiers & Dispersants: Effective as a protective colloid in the emulsion polymerization of vinyl acetate, acrylics, and styrene.

- Water-Soluble Films: Fully hydrolyzed grades like PVA 2699 are ideal for producing environmentally friendly, biodegradable films for packaging and agricultural applications.

Each application leverages the specific rheological and physical properties offered by different grades of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint, ensuring optimal performance and cost-effectiveness. Our technical team works closely with clients to recommend the most suitable PVA grade for their specific formulation needs.

Technical Advantages and Customization

The inherent technical advantages of our Polyvinyl Alcohol products set them apart in the B2B chemical market. These advantages translate directly into enhanced product performance and cost efficiencies for our clients.

- ✓ Superior Adhesion & Binding: Excellent adhesive strength on various substrates, forming strong bonds vital for adhesives and construction materials.

- ✓ Exceptional Film-Forming: Creates durable, flexible, and high-tensile strength films that are vital for barrier coatings and textile sizing.

- ✓ Water Solubility Control: From partially hydrolyzed grades dissolving in cold water to fully hydrolyzed grades requiring hot water, offering precise control for specific application requirements.

- ✓ Biodegradability & Eco-friendliness: Many PVA grades are biodegradable under certain conditions, aligning with global sustainability initiatives.

- ✓ Chemical Resistance: Exhibits good resistance to oils, greases, and organic solvents, enhancing the durability of end products.

- ✓ Emulsifying & Dispersing Properties: Acts as an effective protective colloid, improving the stability and particle size distribution in emulsion systems.

Customized Solutions for Specific Needs:

Recognizing that off-the-shelf solutions may not always meet unique industrial challenges, we specialize in providing customized Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint solutions. Our R&D capabilities allow for tailoring several critical parameters:

- Degree of Hydrolysis: Fine-tuning between 87% and 99% to control water solubility and bonding characteristics.

- Viscosity/Molecular Weight: Adjusting the polymerization degree to achieve desired solution viscosities, critical for rheology control in adhesives and coatings.

- Particle Size Distribution: Custom grinding and sieving to produce powders with specific mesh sizes, optimizing dissolution rates and dispersion for particular application methods.

- Stabilizer Systems: Incorporating specialized additives for enhanced stability in extreme pH or temperature conditions.

This bespoke approach ensures our clients receive a PVA product precisely engineered for their process and end-product requirements, leading to optimized performance and reduced development cycles.

Vendor Comparison and Authoritative Trust

In a competitive market, selecting the right vendor for industrial chemicals like Polyvinyl Alcohol is crucial. Our distinct advantages stem from a combination of unwavering quality, technical expertise, and a robust support infrastructure. When evaluating suppliers for Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint, consider the following critical aspects:

Key Vendor Comparison Metrics:

- • Product Consistency: Our rigorous quality control, backed by ISO 9001:2015 certification, ensures batch-to-batch uniformity, minimizing production variations for our clients.

- • Technical Support & Expertise: Decades of experience in polymer chemistry enable us to offer unparalleled technical guidance, troubleshooting, and formulation advice.

- • Supply Chain Reliability: Strategic sourcing and efficient logistics ensure consistent supply and timely delivery, preventing costly production delays.

- • Customization Capabilities: As highlighted, our ability to tailor PVA grades to exact specifications provides a competitive edge, fostering innovation for our partners.

- • Certifications & Compliance: Adherence to international standards (e.g., ISO, REACH) signifies our commitment to safety, quality, and environmental responsibility.

Authoritative Trust & Certifications:

Our commitment to quality is underscored by our comprehensive certifications and long-standing industry relationships.

- ✓ ISO 9001:2015 Certified: Demonstrates our robust Quality Management System, ensuring consistent product and service quality.

- ✓ REACH Compliant: Our products meet stringent European chemical regulations, affirming product safety and environmental stewardship.

- ✓ Years of Industry Leadership: With over two decades in the chemical supply chain, we have cultivated extensive experience and a proven track record of client satisfaction.

- ✓ Global Partner Network: Serving a diverse clientele spanning across continents, from major chemical corporations to specialized niche manufacturers.

Real-World Application Case Studies

The practical application of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint can be best illustrated through real-world scenarios where its properties delivered significant advantages.

Case Study 1: Enhanced Performance in Dry-Mix Mortars

A leading construction chemicals manufacturer faced challenges with traditional dry-mix mortar formulations, specifically regarding workability and crack resistance. By incorporating our partially hydrolyzed PVA (similar to 2488 grade), they achieved significant improvements.

- • Result: 25% increase in flexural strength and a 15% reduction in crack formation, leading to more durable and aesthetically superior finishes.

- • Benefit: Improved ease of application for contractors and extended service life of structures.

Case Study 2: Optimizing Water-Based Adhesives for Packaging

A packaging solutions provider sought a high-performance, environmentally friendly adhesive for their paper and cardboard laminations. Our technical team recommended a specific fully hydrolyzed PVA grade (akin to 2699) due to its excellent binding properties and biodegradability.

- • Result: Enhanced wet tack and final bond strength, reducing production line slowdowns by 10%.

- • Benefit: Increased production efficiency and adherence to evolving environmental regulations.

Case Study 3: Improving Textile Sizing Efficiency

A textile mill encountered issues with excessive yarn breakage during weaving, impacting production rates and material waste. By switching to our PVA 1799 grade for warp sizing, they observed a significant improvement.

- • Result: Yarn breakage reduced by 18%, and weaving efficiency improved by 5%.

- • Benefit: Substantial cost savings in raw materials and increased throughput.

These examples underscore the tangible benefits and versatility of our Polyvinyl Alcohol products across different industrial applications.

Trustworthiness: FAQ, Lead Time & Support

Frequently Asked Questions (FAQ):

A: These numbers typically refer to the viscosity of a 4% aqueous solution at 20°C (e.g., 24 for 24 mPa.s) and the degree of hydrolysis (e.g., 88 for 88 mol%). This allows for precise selection based on desired solubility and rheological properties.

A: Yes, many grades of PVA are recognized as biodegradable under specific environmental conditions, making them a preferred choice for sustainable applications, especially for the product Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint.

A: PVA powder should be stored in a cool, dry place, in tightly sealed original packaging, away from direct sunlight and moisture. Under these conditions, it can maintain its properties for several years.

Lead Time & Fulfillment Details:

We maintain optimized logistics and inventory management to ensure efficient order fulfillment.

- ▶ Standard Lead Time: Typically 7-14 business days for standard grades and quantities, subject to order size and destination.

- ▶ Customized Orders: Lead times for custom formulations are quoted individually based on complexity and production schedule.

- ▶ Expedited Shipping: Available upon request for urgent requirements.

Warranty Commitments:

All our Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint products are manufactured under strict quality control protocols and come with a comprehensive warranty against manufacturing defects and non-compliance with agreed-upon specifications. Our detailed Certificate of Analysis (CoA) accompanies every shipment, verifying product quality and consistency.

Customer Support Information:

Our dedicated customer support team is available to assist with any technical inquiries, order status updates, or after-sales service.

- ✆ Technical Support: Access to our team of polymer chemists and application engineers for expert advice.

- ✉ Sales & Inquiries: Reach out via our website contact form or direct email for prompt responses.

- 🕑 Service Hours: Available Monday-Friday, 9:00 AM - 5:00 PM (Local Time).

References

1. International Organization for Standardization. ISO 9001:2015 Quality Management Systems – Requirements.

2. European Chemicals Agency (ECHA). REACH Regulation (EC) No 1907/2006.

3. Finch, C. A. (1992). Polyvinyl Alcohol: Basic Properties and Applications. John Wiley & Sons.

4. Gao, Y., Huang, H., & Lin, C. (2018). Advances in Research and Application of Polyvinyl Alcohol in Construction Materials. Journal of Building Materials Science, 1(2), 112-120.

5. Lee, W. F. (2002). Poly(vinyl alcohol): synthesis, properties, and applications. Journal of Macromolecular Science, Part C: Polymer Reviews, 42(4), 481-507.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025