Jun . 13, 2024 09:15

Back to list

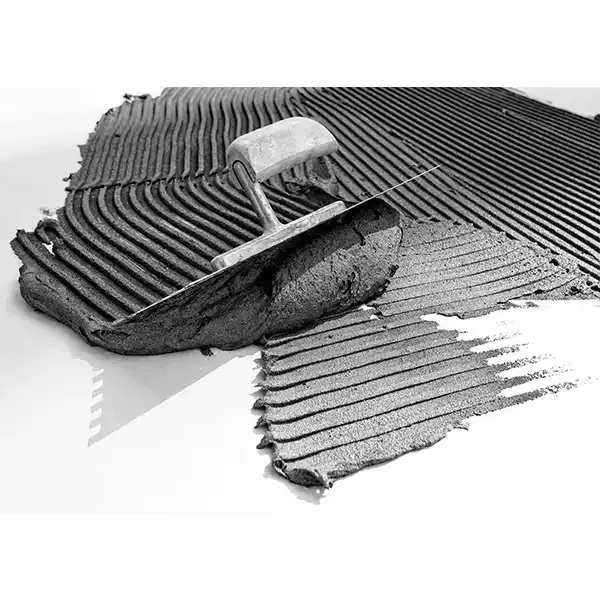

RDP used for ceramic tile bonding adhesive

The Significance of RDP in Ceramic Tile Adhesives

In the world of construction and interior design, ceramic tiles have long been a popular choice for their aesthetic appeal and durability. A critical aspect of ensuring their secure installation is the use of high-quality tile adhesives. One such adhesive that has gained significant attention in recent times is RDP (Rapid Drying Polymer) for ceramic tile adhesive.

RDP technology revolutionizes the tile adhesive industry with its innovative approach to speed and performance. The acronym 'RDP' stands for Rapid Drying Polymer, which as the name suggests, is designed to significantly reduce drying and curing times. This is particularly advantageous in commercial and large-scale projects where time is a crucial factor.

The primary function of an adhesive is to create a strong bond between the tile and the substrate, and RDP-enhanced adhesives excel in this area. They provide excellent bond strength, ensuring that tiles remain firmly in place even under heavy usage or environmental stress. Moreover, RDP adhesives offer superior resistance to water, chemicals, and temperature fluctuations, making them ideal for both indoor and outdoor applications.

One of the standout features of RDP for ceramic tile adhesive is its environmentally friendly nature. Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process

Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.

The rapid drying property of RDP adhesives allows for quicker project completion and earlier access to the installation area. It reduces downtime, thereby improving productivity and efficiency on the job site. The ability to apply multiple layers in a shorter period is a significant advantage, especially in situations where deadlines are tight.

Furthermore, RDP technology also enhances the flexibility and workability of the adhesive. This means that tiles can be easily adjusted or corrected during the installation process, reducing waste and increasing overall job satisfaction.

In conclusion, RDP for ceramic tile adhesive represents a significant step forward in tile installation technology. Its combination of speed, strength, durability, and eco-friendliness makes it a preferred choice for professionals and DIY enthusiasts alike. As the construction industry continues to evolve, RDP-adhesive technology promises to play a pivotal role in enhancing efficiency, sustainability, and the overall quality of tile installations.

rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.

The rapid drying property of RDP adhesives allows for quicker project completion and earlier access to the installation area. It reduces downtime, thereby improving productivity and efficiency on the job site. The ability to apply multiple layers in a shorter period is a significant advantage, especially in situations where deadlines are tight.

Furthermore, RDP technology also enhances the flexibility and workability of the adhesive. This means that tiles can be easily adjusted or corrected during the installation process, reducing waste and increasing overall job satisfaction.

In conclusion, RDP for ceramic tile adhesive represents a significant step forward in tile installation technology. Its combination of speed, strength, durability, and eco-friendliness makes it a preferred choice for professionals and DIY enthusiasts alike. As the construction industry continues to evolve, RDP-adhesive technology promises to play a pivotal role in enhancing efficiency, sustainability, and the overall quality of tile installations.

Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process

Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.

The rapid drying property of RDP adhesives allows for quicker project completion and earlier access to the installation area. It reduces downtime, thereby improving productivity and efficiency on the job site. The ability to apply multiple layers in a shorter period is a significant advantage, especially in situations where deadlines are tight.

Furthermore, RDP technology also enhances the flexibility and workability of the adhesive. This means that tiles can be easily adjusted or corrected during the installation process, reducing waste and increasing overall job satisfaction.

In conclusion, RDP for ceramic tile adhesive represents a significant step forward in tile installation technology. Its combination of speed, strength, durability, and eco-friendliness makes it a preferred choice for professionals and DIY enthusiasts alike. As the construction industry continues to evolve, RDP-adhesive technology promises to play a pivotal role in enhancing efficiency, sustainability, and the overall quality of tile installations.

rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.

The rapid drying property of RDP adhesives allows for quicker project completion and earlier access to the installation area. It reduces downtime, thereby improving productivity and efficiency on the job site. The ability to apply multiple layers in a shorter period is a significant advantage, especially in situations where deadlines are tight.

Furthermore, RDP technology also enhances the flexibility and workability of the adhesive. This means that tiles can be easily adjusted or corrected during the installation process, reducing waste and increasing overall job satisfaction.

In conclusion, RDP for ceramic tile adhesive represents a significant step forward in tile installation technology. Its combination of speed, strength, durability, and eco-friendliness makes it a preferred choice for professionals and DIY enthusiasts alike. As the construction industry continues to evolve, RDP-adhesive technology promises to play a pivotal role in enhancing efficiency, sustainability, and the overall quality of tile installations. Latest news

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025