Hydroxypropyl Methyl Cellulose (HPMC) is a versatile chemical additive that has revolutionized the construction industry. As a key component in tile adhesives, HPMC improves the performance of cement mortars, ceramic tile cements, and refractory coatings. This article explores the features, technical specifications, application scenarios, and the company behind this innovative product.

Understanding Hydroxypropyl Methyl Cellulose (HPMC)

HPMC is a modified cellulose ether derived from highly pure cotton fibers through a specialized etherification process under alkaline conditions. This chemical compound is renowned for its thickening ability, salt resistance, low ash content, pH stability, water retention, dimensional stability, and excellent film-forming properties. Its versatility makes it a critical ingredient in construction materials, where it enhances workability, adhesion, and durability.

Key Features of HPMC

- Water Retention: HPMC significantly improves the water retention of cement-based materials, ensuring proper hydration and reducing cracking.

- Adhesion: It enhances the adhesion of tile adhesives to substrates, ensuring long-term stability even in challenging environments.

- Workability: HPMC improves the workability of mortars and pastes, making them easier to apply and reducing labor costs.

- Stability: Its pH stability ensures consistent performance across a wide range of conditions, while its low ash content minimizes impurities.

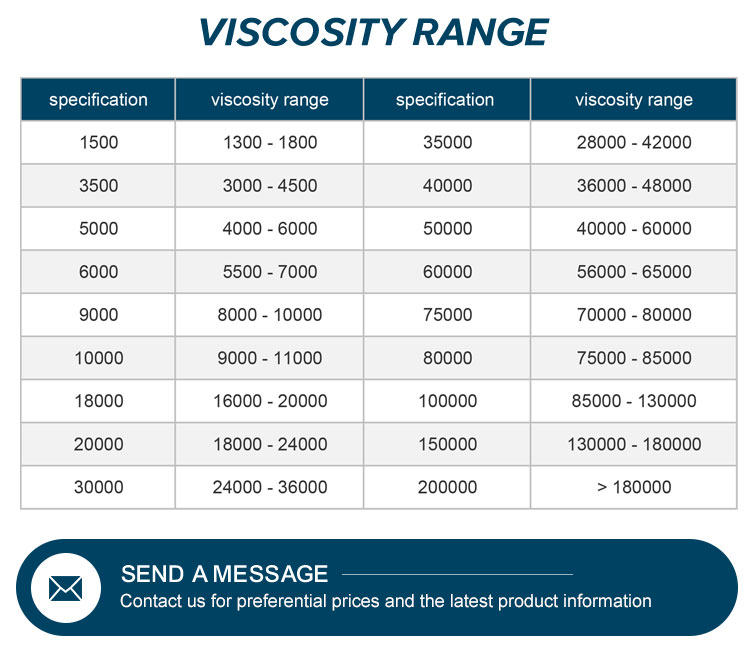

Technical Specifications of HPMC

| Parameter | Specification |

|---|---|

| Appearance | Milky white or white powder |

| Carbonization Temperature | 280-300°C |

| Color Temperature | 190-200°C |

| Particle Size | 100 mesh pass rate >98.8%; 80 mesh pass rate 99.9%; Special specifications: 40-60 mesh |

| Apparent Density | 0.25-0.70 g/cm³ (typically 0.5 g/cm³) |

| Specific Gravity | 1.26-1.31 |

| Solubility | Soluble in water and certain solvents (e.g., ethanol/water, propanol/water) |

Application Scenarios in Construction

HPMC is widely used in various construction applications due to its exceptional properties. Below are some key scenarios:

1. Cement Mortar

HPMC enhances the workability and water retention of cement mortars, reducing the risk of cracking and ensuring a smooth finish. It also improves the adhesion of the mortar to the substrate, making it ideal for both interior and exterior applications.

2. Ceramic Tile Cement

In ceramic tile installations, HPMC ensures strong adhesion between the tiles and the substrate. Its water retention properties prevent the mortar from drying too quickly, allowing for better bonding and a more durable finish.

3. Refractory Coatings

HPMC acts as a suspension agent and fluidity improver in asbestos and other refractory coatings. It enhances the adhesion of these coatings to substrates, ensuring long-term protection against high temperatures.

4. Gypsum Coagulant Slurry

When added to gypsum coagulant slurry, HPMC improves water retention and workability, ensuring a more uniform application and stronger adhesion to the substrate.

5. Joint Cement

HPMC is used in joint cement for gypsum boards to improve fluidity and water retention, resulting in stronger and more durable joints.

About the Company: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. is a leading manufacturer of chemical additives, specializing in the production of Hydroxypropyl Methyl Cellulose (HPMC). With a commitment to quality and innovation, the company has established itself as a trusted supplier in the construction industry. Their products are used globally, providing reliable solutions for a wide range of applications.

Founded with a focus on research and development, Yongfeng Cellulose ensures that its HPMC meets the highest standards of performance and safety. The company adheres to strict quality control measures, ensuring that each batch of HPMC is consistent in quality and meets international certifications.

Why Choose HPMC for Your Construction Projects?

HPMC offers numerous advantages that make it an essential component in modern construction. Here are some reasons to consider using HPMC in your projects:

- Enhanced Workability: HPMC improves the consistency and flow of cement-based materials, making them easier to apply and reducing the risk of defects.

- Improved Adhesion: Its ability to enhance adhesion ensures that tiles and coatings remain securely attached, even in challenging conditions.

- Durability: HPMC contributes to the long-term durability of construction materials, reducing the need for frequent repairs and maintenance.

- Cost-Effectiveness: By improving the efficiency of construction processes, HPMC helps reduce labor and material costs over time.

Industry Standards and Certifications

HPMC is manufactured in compliance with international standards for chemical additives. The product meets the requirements of NIST (National Institute of Standards and Technology) for quality and performance. NIST's research on construction materials ensures that products like HPMC are reliable and effective in real-world applications.

For more information on NIST's role in advancing construction technology, visit NIST's official website.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) is a critical chemical additive that enhances the performance of construction materials. Its unique properties, including water retention, adhesion, and workability, make it an indispensable component in tile adhesives, cement mortars, and refractory coatings. Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. continues to lead the way in providing high-quality HPMC solutions that meet the demands of the construction industry.

By choosing HPMC, construction professionals can ensure the durability, efficiency, and cost-effectiveness of their projects. Whether you're working on residential, commercial, or industrial applications, HPMC offers a reliable solution that stands the test of time.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards for Construction Materials. Retrieved from https://www.nist.gov/.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.. (n.d.). HPMC Product Specifications. Retrieved from https://www.youngcel.com/hpmc/.

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025