The Role of Cellulose in Paints Enhancing Quality and Performance

Cellulose, a natural polymer derived from plant cell walls, has emerged as an essential ingredient in the formulation of various paints. Its unique properties not only improve the paints' quality but also contribute to sustainable practices within the coatings industry. This article delves into the significance of cellulose in paints, exploring its advantages and the diverse roles it plays.

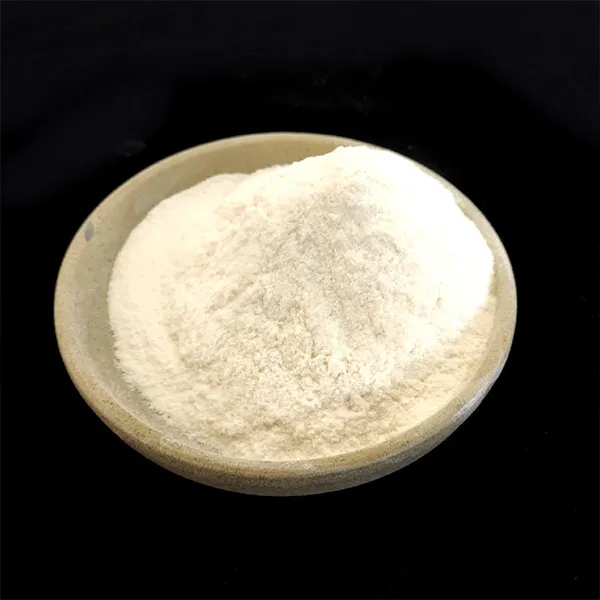

1. Nature and Types of Cellulose

Cellulose, a carbohydrate composed of linear chains of glucose units, is the most abundant organic polymer on Earth. In the paint industry, it is typically utilized in various forms, including cellulose ethers and cellulose esters. These derivatives, such as hydroxypropyl methylcellulose (HPMC) and carboxymethyl cellulose (CMC), are favored for their solubility in water and organic solvents, making them versatile additives in paint formulations.

2. Enhancing Viscosity and Stability

One of the primary roles of cellulose in paints is its ability to modify viscosity. When incorporated into a paint formulation, cellulose derivatives can thicken the paint, improving its application properties. This increased viscosity helps the paint to sit well on vertical surfaces, reducing the risk of dripping and sagging during application. Moreover, cellulose acts as a stabilizing agent, preventing the separation of components during storage. This ensures a consistent product that maintains quality over time.

3. Improving Applicability and Coverage

Cellulose not only enhances viscosity but also improves the applicability of paints. The presence of cellulose allows for better control over the spreading and leveling of paint, leading to smoother finishes. This is particularly beneficial in high-quality decorative paints and coatings. Additionally, cellulose can improve the coverage of paint, reducing the number of coats required to achieve the desired opacity. This efficiency not only saves time during application but also reduces material costs.

cellulose for paints

4. Environmental Benefits

In an era increasingly concerned with sustainability, the use of cellulose in paint formulations aligns with eco-friendly practices. Being a natural and biodegradable product, cellulose adds to the environmental credentials of paints, especially when compared to synthetic thickening agents. Furthermore, many cellulose derivatives are derived from renewable resources, supporting a more sustainable manufacturing approach. This shift towards greener ingredients is steadily gaining traction in the coatings industry.

5. Contributing to Performance Attributes

Cellulose plays a vital role in improving various performance attributes of paints. For instance, it can enhance the water retention capability of coatings, which is crucial during the drying process. More cohesive drying can lead to a reduction in defects such as cracks and peeling. Additionally, cellulose can enhance the film-forming properties of paints, contributing to the overall durability and longevity of the applied coating.

6. Challenges and Considerations

Despite its numerous advantages, the use of cellulose in paint formulations is not without challenges. The sourcing and processing of cellulose must be managed to ensure quality and cost-effectiveness. Furthermore, formulators must balance the incorporation of cellulose to achieve the desired characteristics without negatively impacting other properties, such as drying time or gloss levels.

Conclusion

In conclusion, cellulose has established itself as an invaluable component in the realm of paints. Its ability to enhance viscosity, improve applicability, and contribute to sustainable practices makes it a preferred choice for many formulators. As the industry continues to evolve, the role of cellulose in paints will likely expand, driving innovation towards more efficient and environmentally friendly solutions. Embracing cellulose not only benefits manufacturers but also supports consumers in seeking high-quality, sustainable products for their painting needs.

-

Premium Detergent Grade HPMC Hydroxypropyl Methylcellulose: Superior Thickening & StabilityNewsAug.31,2025

-

HEC 100000 Hydroxyethylcellulose for Paint | Superior ThickeningNewsAug.30,2025

-

Wall Putty Rdp Powder Packaging DesignNewsAug.29,2025

-

Introduction to Hpmc Hydroxypropyl Methyl CellulosNewsAug.29,2025

-

Hpmc Industri Grade IntegrationNewsAug.29,2025

-

How to Choose the Right Construction AdhesiveNewsAug.29,2025