Jan . 22, 2025 05:25

Back to list

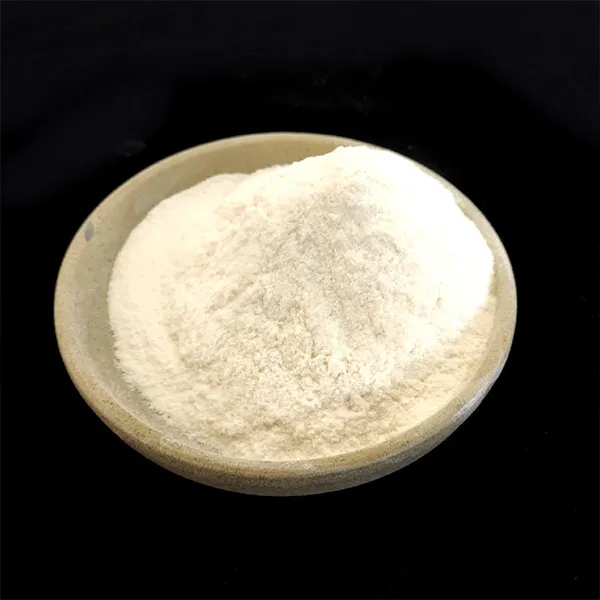

Increase Detergent Viscosity Water Binding Agent Hpmc For Alcohol Based Liquid Detergent

When it comes to home improvement and renovation, ensuring the quality and longevity of wall finishes is crucial. One solution that has gained attention in the construction arena is the use of white powder HPMC (Hydroxypropyl Methylcellulose) in wall putty applications. This wonder additive revolutionizes wall preparation, enhancing durability, adherence, and smoothness.

The professional construction community acknowledges the impact of HPMC on the durability of wall putty. Tests and field trials reveal that walls treated with HPMC-based putty withstand environmental stressors far better than conventional putty formulations. This characteristic is crucial for developers aiming to construct buildings that require minimal maintenance and offer maximum lifespan. Moreover, HPMC's ability to enhance adhesion ensures that decorative layers, such as paint or wallpaper, adhere more robustly to the wall surface. The strong bond created by HPMC-treated putty prevents issues such as peeling or blistering, which can mar the aesthetic appeal and structural integrity of the wall finish. This attribute is invaluable for interior designers and contractors focused on delivering high-quality, enduring finishes. Homeowners who have chosen wall putty with HPMC have expressed satisfaction not only with the initial appearance but also with the lasting quality of their wall surfaces. It addresses common concerns such as cracks, chips, and uneven application, thereby preserving property value and reducing future renovation costs. Such testimonials bolster the credibility of HPMC as a reliable and effective component in wall finishing products. In summary, white powder HPMC for wall putty is a pivotal advancement in construction materials. With its superior water retention, adhesion, and stability characteristics, it enhances the overall quality and efficiency of wall preparation and finishing processes. Professional builders, developers, and homeowners alike recognize its value in delivering smooth, durable, and visually appealing wall surfaces. As the construction industry continues to evolve, the adoption of HPMC in wall putty represents a commitment to quality and innovation that meets the demands of modern construction projects.

The professional construction community acknowledges the impact of HPMC on the durability of wall putty. Tests and field trials reveal that walls treated with HPMC-based putty withstand environmental stressors far better than conventional putty formulations. This characteristic is crucial for developers aiming to construct buildings that require minimal maintenance and offer maximum lifespan. Moreover, HPMC's ability to enhance adhesion ensures that decorative layers, such as paint or wallpaper, adhere more robustly to the wall surface. The strong bond created by HPMC-treated putty prevents issues such as peeling or blistering, which can mar the aesthetic appeal and structural integrity of the wall finish. This attribute is invaluable for interior designers and contractors focused on delivering high-quality, enduring finishes. Homeowners who have chosen wall putty with HPMC have expressed satisfaction not only with the initial appearance but also with the lasting quality of their wall surfaces. It addresses common concerns such as cracks, chips, and uneven application, thereby preserving property value and reducing future renovation costs. Such testimonials bolster the credibility of HPMC as a reliable and effective component in wall finishing products. In summary, white powder HPMC for wall putty is a pivotal advancement in construction materials. With its superior water retention, adhesion, and stability characteristics, it enhances the overall quality and efficiency of wall preparation and finishing processes. Professional builders, developers, and homeowners alike recognize its value in delivering smooth, durable, and visually appealing wall surfaces. As the construction industry continues to evolve, the adoption of HPMC in wall putty represents a commitment to quality and innovation that meets the demands of modern construction projects.

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025