High-performance cellulose ether for modern job sites: what contractors keep asking me

I’ve spent enough mornings on mixing decks and QC labs to know when a material simply “clicks.” The first time I trialed High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder in a tile adhesive, the trowel feel changed instantly—creamier glide, steadier ridges, and, crucially, tiles stayed put even on thirsty block. Contractors notice that kind of difference fast.

Why it’s trending

In dry-mix mortars, gypsum plasters, EIFS/ETICS, and putties, a high-viscosity HPMC isn’t a nice-to-have anymore—it’s the backbone for water retention, workability, and anti-sag. Energy-efficient envelopes and larger-format tiles push chemistries harder, and, to be honest, additives must do more with less. Many customers say this grade balances open time with early strength better than the “usual suspects.”

What it is (and what it isn’t)

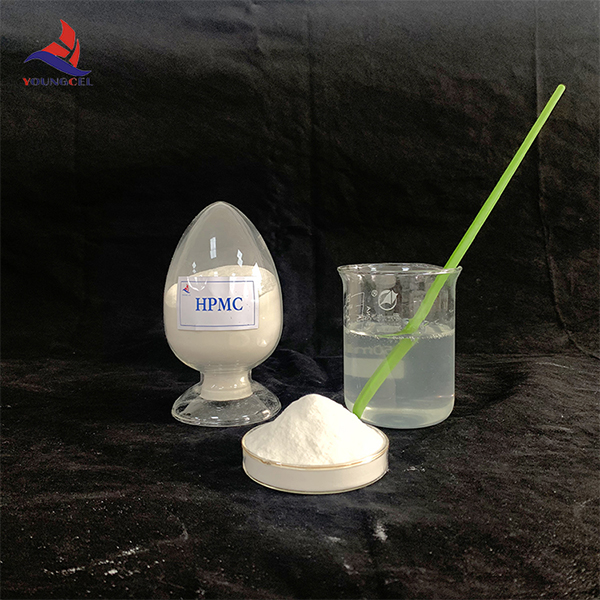

High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is a refined cellulose ether derived from cotton cellulose. It’s supplied as a free-flowing powder but acts in liquid systems (coatings, cement, gypsum) as a protective colloid and rheology modifier—hence the “liquid coating” mention you sometimes see on data sheets. CAS 9004-65-3, EINECS 231-545-4, made in China, from Gaocheng District, Shijiazhuang, Hebei—yes, that hub where cellulose science is almost a neighborhood skill.

Typical product specifications (lab values ≈, real-world use may vary)

| Parameter | Spec (≈) | Test/Note |

|---|---|---|

| Viscosity | 45,000–90,000 mPa·s | 2% sol., Brookfield LV, 20±1°C |

| Methoxy content | 19–24% | Titration |

| Hydroxypropyl content | 4–12% | GC/IR |

| Moisture | ≤5.0% | 105°C, 2 h |

| pH (1% sol.) | 6.0–8.5 | 25°C |

| Residue on 80 mesh | ≤5% | Particle size |

| Ash | ≤1.5% | Sulfated ash |

| Gel temperature | 60–75°C | Hot water method |

Where it shines

- Tile adhesives (EN 12004): anti-slip, long open time, improved wet tack.

- Wall putty/skimming: buttery spread, reduced pinholes, better sanding.

- Gypsum plaster (ASTM C472): sag control, crack resistance, body.

- EIFS basecoat: fiber synergy, stable bead hold, workable window.

- Self-leveling (with lower-vis grade blend): edge stability, bleeding control.

Advantages we kept hearing from sites: predictable water demand, forgiving mixing, and fewer callbacks. Actually, the reduced slump on verticals is what foremen rave about.

Process, QA, and service life

Materials and method (simplified): purified cotton cellulose → alkalization → etherification (methyl chloride + propylene oxide) → neutralization → washing → drying → milling → sieving → QC release.

Testing standards reference: mortar flow (ASTM C1437), tensile adhesion (EN 12004), water retention (EN 1015-8), workability window (lab methods). Shelf life: around 24 months in dry, cool storage; performance in mortar remains stable across typical project timelines.

Vendor snapshot (pragmatic view)

| Vendor | Consistency | Customization | Certs | Notes |

|---|---|---|---|---|

| Youngcel (Hebei) | High (batch-to-batch ≈2–3% var.) | Viscosity, DS/MS, delayed solubility | ISO 9001, REACH-ready | Fast tech support; lab blends on request |

| Generic A | Medium | Limited | ISO only | Lead times fluctuate |

| Generic B | Medium–High | Viscosity | ISO, partial REACH | Competitive pricing |

Customization options

- Viscosity grades for spray, trowel, or pumpable systems.

- Surface treatment for delayed solubility (clean dispersion in high-speed mixers).

- Particle size tuning to reduce dusting and speed wet-out.

- Blend design with starch ether/redispersible powders—on spec.

Quick case notes

- Middle East tile crew: switched to High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder, open time increased ≈10–15 min, saving rework on façade panels.

- South Asia putty brand: smoother drawdown, fewer drag marks; sanding complaints dropped noticeably—sales team was relieved.

- Central Europe EIFS basecoat: less bead slump in warm weather; tensile adhesion met EN 13494 targets with margin.

Compliance, logistics, and a tiny digression

REACH/RoHS-friendly, low VOC by nature, and supplied with COA per batch. Production and dispatch from No.1 Shifu East Road, Gaocheng District, Shijiazhuang, Hebei, China. Packaging: multi-layer paper bags with PE liner, 25 kg standard. And yes, store it like a pro—dry, away from heat; it’s boring advice that saves money.

If your formulation sits on the edge—say, heavy porcelain tiles or fast-track gypsum—ask for a pilot blend. In fact, a small viscosity tweak or surface treatment on High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder can be the difference between “almost there” and “don’t touch it, it’s perfect.”

Authoritative references

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025