Understanding Additives for Concrete Enhancing Performance and Durability

Concrete is one of the most widely used construction materials in the world, valued for its strength, durability, and versatility. However, the inherent properties of concrete can be improved through the use of various additives. These additives are crucial in optimizing the performance of concrete to meet specific project requirements. This article explores the types of concrete additives, their functions, and the benefits they provide in construction.

Types of Concrete Additives

Concrete additives can be broadly classified into two main categories chemical additives and mineral additives.

1. Chemical Additives These are substances added to the concrete mix to modify its properties. They include

- Water Reducers These additives decrease the amount of water needed for the mix while maintaining workability. This reduction in water can enhance the strength of the final product, as less water leads to a denser concrete.

- Superplasticizers A more advanced type of water reducer, superplasticizers allow for significant water reduction without compromising workability. These are crucial for high-strength concrete applications and projects requiring complex shapes.

- Set Retarders Used to delay the setting time of concrete, these additives are beneficial in hot weather conditions to prevent premature hardening, allowing more time for placement and finishing.

- Set Accelerators Conversely, set accelerators speed up the setting and hardening process. They are ideal for cold weather applications and can significantly reduce the curing time.

- Air-Entraining Agents These additives create tiny air bubbles within the concrete, improving its resistance to freeze-thaw cycles and enhancing workability. This is particularly important in regions with severe weather conditions.

2. Mineral Additives These are finely ground materials that can partially replace cement in concrete mixes. Common mineral additives include

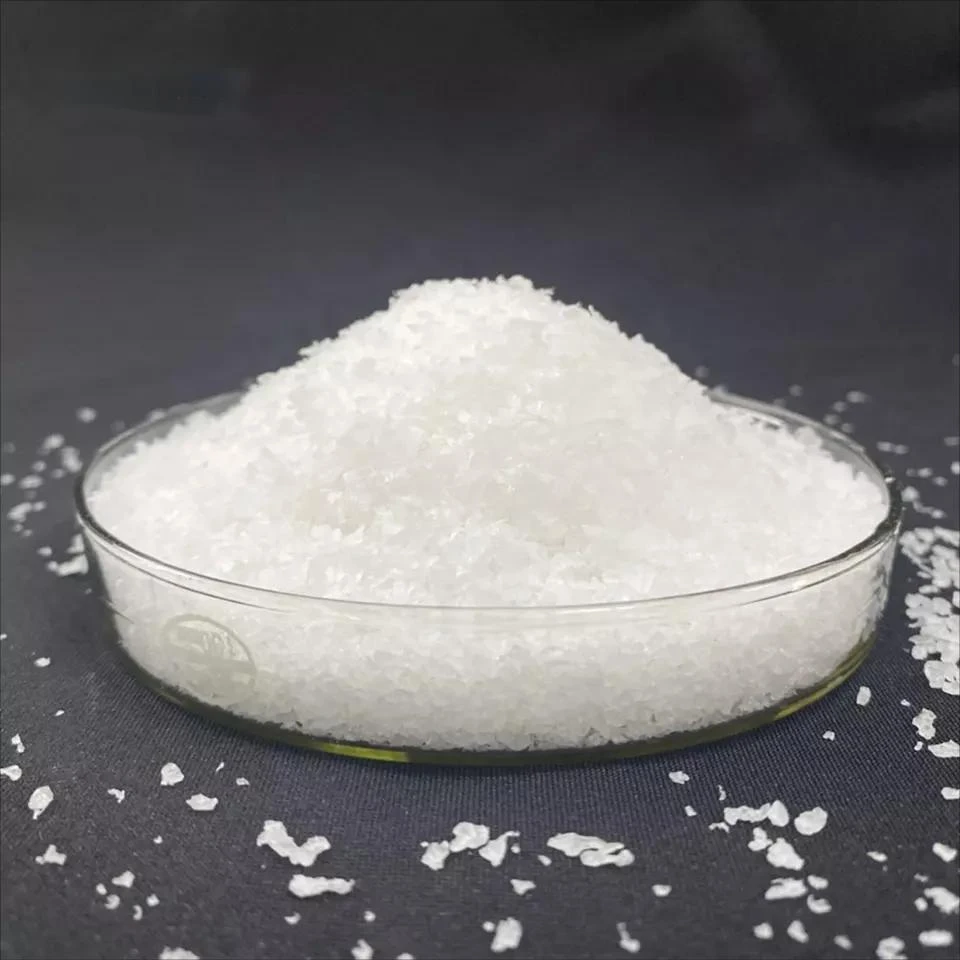

additive for concrete

- Fly Ash A byproduct of coal combustion, fly ash can improve workability, increase long-term strength, and reduce permeability in concrete.

- Silica Fume A byproduct of silicon metal production, silica fume is known for its high pozzolanic activity. It enhances strength and durability, particularly in high-performance concrete applications.

- Limestone Powder Used as a filler, limestone powder can improve the cohesive properties of concrete and enhance the overall strength.

Benefits of Using Additives

The incorporation of additives into concrete mixes yields numerous advantages.

- Enhanced Workability Additives like superplasticizers and water reducers greatly improve the workability of concrete, making it easier to place and finish, particularly for intricate designs and high-rise constructions.

- Strength and Durability Through the use of chemical and mineral additives, concrete can achieve higher compressive strengths and increased durability. This leads to longer-lasting infrastructure and reduced maintenance costs.

- Cost-Effectiveness By replacing a portion of cement with additives such as fly ash or silica fume, costs can be minimized while maintaining performance standards. Cement is often the most expensive ingredient in concrete; therefore, reducing its use without compromising quality is economically beneficial.

- Environmental Benefits Many mineral additives are industrial byproducts, helping to divert waste from landfills. Additionally, using less cement in mixtures reduces the overall carbon footprint of concrete production—a vital consideration in today’s eco-conscious environment.

Conclusion

Concrete additives play a significant role in modern construction practices. By selecting the appropriate additives, engineers and builders can tailor concrete mixtures to suit specific project requirements, enhancing performance characteristics and overall durability. As construction practices continue to evolve, the use of innovative concrete additives will be essential in creating sustainable, efficient, and resilient structures. The future of concrete is not just about its essential materials; it is also about the additives that can transform it into a superior building material.

-

Rdp that The Revolutionary Polymer Powder Transforming Modern Construction MaterialsNewsAug.11,2025

-

Hpmc Powder that Versatile Additive for Detergents and Personal CareNewsAug.11,2025

-

Hpmc Hydroxypropyl Methylcellulose that Essential Building Material Additive from Shijiazhuang Gaocheng YongfengNewsAug.11,2025

-

Hydroxypropyl Methyl Cellulos Hpmc that Essential for Construction ApplicationsNewsAug.11,2025

-

Mhec Powder that Revolutionizing Construction Chemistry with Cellulose Ether SolutionsNewsAug.11,2025

-

Industri Hpmc that The Global Backbone of Advanced ConstructionNewsAug.11,2025