The Versatility and Applications of HPMC Mortar

Hydroxypropyl Methylcellulose (HPMC) has gained significant attention in the construction industry, particularly as an additive in mortars and other cement-based products. This non-ionic cellulose ether is derived from natural cellulose and has been widely employed due to its unique properties, making it an essential ingredient for various applications. In this article, we will delve into the benefits, composition, applications, and future potential of HPMC mortar.

What is HPMC?

HPMC is a white, odorless powder that is soluble in water, forming a clear, viscous solution. Its chemical modifications allow it to exhibit various functional capabilities, including improved workability, water retention, and adhesion. These features make it an ideal additive for mortars, tile adhesives, plasters, and other formulations in the construction sector.

Benefits of HPMC in Mortar

1. Enhanced Workability One of the key advantages of incorporating HPMC into mortar is its ability to improve workability. The addition of HPMC allows for smoother mixing and spreading, which is crucial during application. This property is especially beneficial for large-scale projects where consistent application quality is crucial.

2. Water Retention HPMC has excellent water retention properties, preventing premature drying of mortar. This is vital for ensuring proper hydration of cement, leading to better strength development. Extended open time means that workers can adjust and clean up without the mortar setting too quickly.

3. Adhesion and Bond Strength HPMC enhances the bonding properties of mortars, allowing them to adhere better to various substrates, such as concrete, brick, and tile. This makes it an ideal choice for tile adhesives, where strong adhesion is required to ensure long-lasting durability.

4. Frost Resistance Mortars containing HPMC can exhibit improved resistance to freezing and thawing cycles. This is particularly important in climates where temperatures fluctuate, as the risk of crack formation due to freeze-thaw stress is mitigated.

5. Green Building Certification As sustainability becomes a major concern in construction, HPMC offers environmental advantages. Being derived from natural cellulose, it contributes to green building certifications, appealing to environmentally conscious consumers and builders.

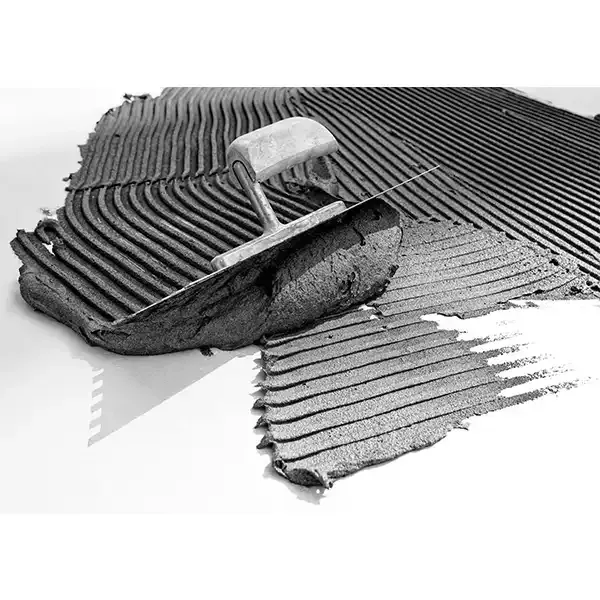

hpmc mortar

Applications of HPMC Mortar

HPMC mortar is versatile and can be utilized in various construction applications

- Tile Adhesives The most common use of HPMC is in tile adhesives, where its superior adhesion and water retention qualities ensure tiles remain securely bonded to surfaces. - Plasters HPMC can be added to plaster formulations to enhance workability, open time, and water retention, resulting in smoother finishes and improved durability.

- Repair Mortars In repair applications, HPMC can be used to modify mortars to enhance strength and adhesion, making it suitable for restoring damaged structures.

- Renderings For external renderings, HPMC-infused mortars provide excellent weather resistance and adaptability to various environments.

Future Trends

As the construction industry evolves, the demand for advanced materials like HPMC mortar is expected to grow. Ongoing research aims to further improve the performance of HPMC by exploring sustainable sources and more efficient production methods. Moreover, the increasing focus on eco-friendly construction practices will likely lead to the development of innovative formulations incorporating HPMC.

The rise of smart construction technologies also poses new opportunities for HPMC mortar. As building techniques become more sophisticated, the integration of HPMC into new products tailored for modern construction challenges will become more prevalent.

In conclusion, HPMC mortar stands out as a versatile and highly beneficial material in the construction industry. With its enhanced workability, water retention, adhesion, and frost resistance, it meets the demands of modern construction practices. As we move toward a more sustainable future, the role of HPMC in creating efficient and durable building solutions will undoubtedly expand, paving the way for innovative applications that meet the challenges of the evolving construction landscape.

-

Rdp that The Revolutionary Polymer Powder Transforming Modern Construction MaterialsNewsAug.11,2025

-

Hpmc Powder that Versatile Additive for Detergents and Personal CareNewsAug.11,2025

-

Hpmc Hydroxypropyl Methylcellulose that Essential Building Material Additive from Shijiazhuang Gaocheng YongfengNewsAug.11,2025

-

Hydroxypropyl Methyl Cellulos Hpmc that Essential for Construction ApplicationsNewsAug.11,2025

-

Mhec Powder that Revolutionizing Construction Chemistry with Cellulose Ether SolutionsNewsAug.11,2025

-

Industri Hpmc that The Global Backbone of Advanced ConstructionNewsAug.11,2025