Exploring HPMC Mortar Properties and Applications

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer used extensively in various construction applications, particularly in cement-based mortars. As a significant component in High-Performance Mortar, HPMC enhances the physical properties of the mortar, making it a crucial additive for modern construction practices.

Composition and Properties

HPMC is derived from natural cellulose through a series of chemical processes that modify its structure. This modification imparts hydrophilic properties, making HPMC soluble in water while retaining its polymer nature, which contributes to the desired performance characteristics of mortars.

One of the key features of HPMC is its ability to improve workability. By increasing the water retention capability of the mortar, HPMC allows for better bonding with the substrate and prolongs open time, making it easier for contractors to manipulate the material without compromising the structural integrity. The enhanced water retention means that the mortar remains workable longer, allowing for extended application periods and improving the overall efficiency of installation processes.

Another critical property is the improvement in adhesion and flexibility. Mortars with HPMC additives demonstrate superior binding strength to various substrates, including concrete, bricks, and tiles. This improves the durability of the structures and minimizes the risks of cracking or delamination, particularly in environments subject to thermal expansion and contraction.

Applications in the Construction Industry

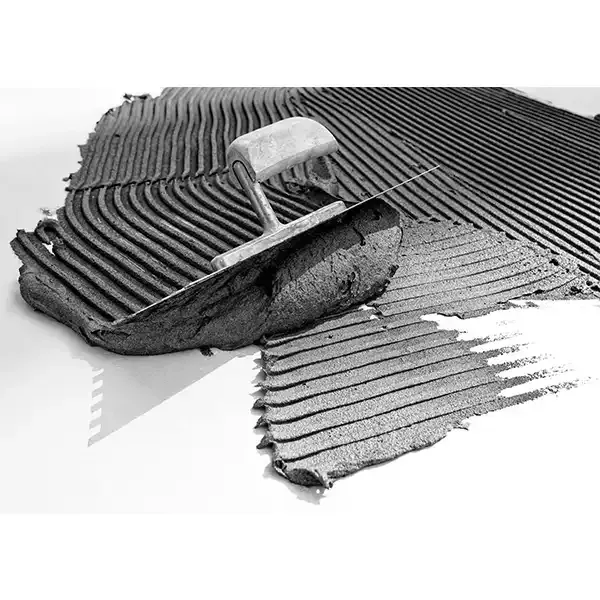

hpmc mortar

HPMC is widely used in tile adhesives, exterior insulation and finishing systems (EIFS), self-leveling compounds, and repair mortars. In tile adhesives, for instance, the inclusion of HPMC ensures that the adhesive remains pliable long enough for proper positioning and adjustments without losing its bonding capabilities. This characteristic is invaluable in tiling applications where precision is critical.

In addition to its use in adhesives, HPMC’s water-retaining properties are particularly beneficial for self-leveling screeds. By maintaining moisture levels, HPMC helps ensure a smooth, even surface while reducing the risk of cracking during the curing process.

Moreover, HPMC is often incorporated into mortars utilized for external applications, such as façades and cladding systems. The polymer's enhanced flexibility and adhesion properties promote the longevity of these structures while also improving their aesthetic appeal.

Environmental Considerations

With increasing awareness of sustainable construction practices, HPMC serves as a favorable option due to its non-toxic nature and compatibility with eco-friendly materials. As construction continues to evolve towards greener solutions, the role of additives like HPMC will likely expand, providing efficient, durable, and sustainable building materials.

Conclusion

In summary, HPMC plays a pivotal role in enhancing the performance of mortars across various construction applications. Its properties of improved workability, adhesion, and flexibility make it an essential ingredient for high-quality mortars that meet the demands of modern construction. As advancements in building materials continue, HPMC will undoubtedly be at the forefront, contributing to more durable, efficient, and sustainable construction practices. Its ability to cater to both technical and environmental needs positions HPMC as a key player in the future of the construction industry.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025