The Importance of Raw Materials in the Chemical Industry

In the contemporary world, the chemical industry serves as a backbone for numerous sectors, including pharmaceuticals, agriculture, manufacturing, and consumer goods. At the heart of this expansive industry lies the concept of raw materials, particularly powders derived from chemicals. These materials are vital for producing a plethora of products, ranging from medicines to fertilizers and industrial chemicals.

Understanding Raw Materials and Their Classification

Raw materials are the basic inputs used in the production of goods. When it comes to the chemical industry, these materials can be organic or inorganic compounds, often supplied in powdered form to facilitate ease of handling and processing. Chemical raw materials can be grouped into several categories, including

1. Organic Chemicals Derived from living organisms or synthetic processes, these include compounds such as solvents, acids, and alcohols which play crucial roles in various chemical reactions.

2. Inorganic Chemicals These are not based on carbon-hydrogen bonds and include salts, metals, and minerals. They often serve as catalysts, reactants, or stabilizers in chemical formulations.

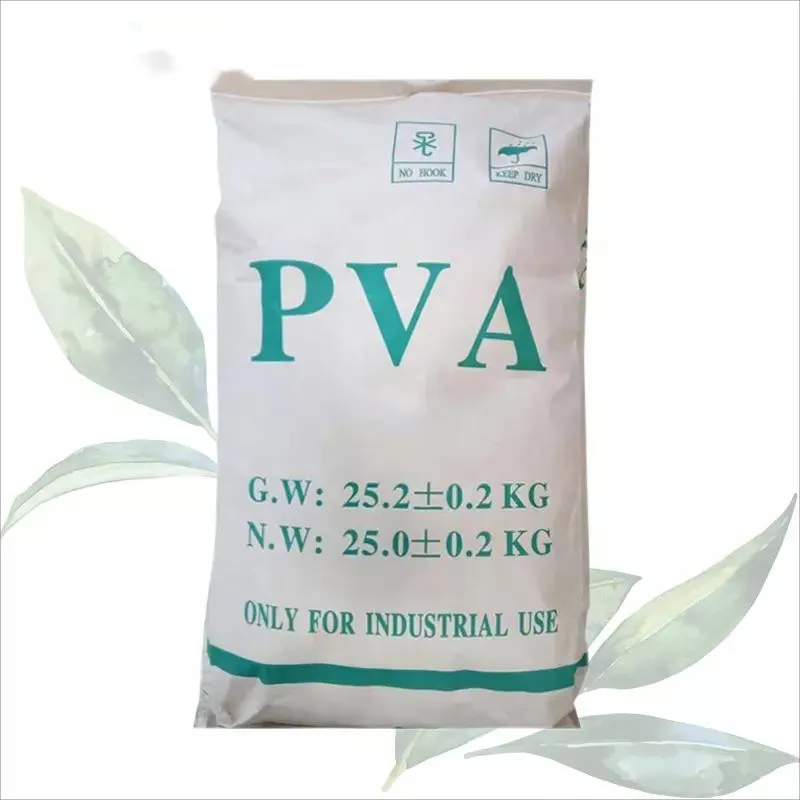

3. Polymers Frequently utilized in the production of plastics and elastomers, polymers are made up of long molecular chains and can be found in powdered form.

4. Minerals and Metal Powders These materials serve as essential feedstock for the manufacturing of steel, aluminum products, and a diverse range of metal-based chemicals.

Benefits of Using Powdered Raw Materials

The transition from bulk materials to powdered forms in the chemical industry has numerous advantages

1. Improved Reactivity Finely powdered materials often have a larger surface area compared to their bulk counterparts, allowing for better reactivity during chemical processes. This leads to enhanced reaction rates and increased product yields.

2. Ease of Transport and Handling Powders are generally lighter and easier to transport than large solid chunks or liquids. This ease of handling allows for more efficient logistics, reducing the overall cost of raw material procurement.

chemicals raw materials powder

3. Versatility Powdered materials can be easily blended with other components to create customized formulations suited for specific applications. This adaptability makes them invaluable in creating a variety of products.

4. Controlled Dosing The consistency in particle size of powdered materials facilitates precise dosing during manufacturing processes, ensuring uniformity in the final products. This is crucial, especially in industries such as pharmaceuticals, where dosage accuracy is paramount.

Challenges in the Use of Powdered Materials

Despite their advantages, working with powdered raw materials does come with its own set of challenges

1. Handling Hazards Fine powders can pose inhalation risks or create explosive atmospheres if proper safety measures are not adhered to. Therefore, industries must implement stringent safety protocols.

2. Storage Issues Powders can be prone to caking, moisture absorption, or degradation over time, necessitating careful storage solutions to maintain their efficacy and shelf life.

3. Processing Challenges Various processing techniques, such as mixing, granulation, or compaction, may be required to ensure the desired properties in the final product. This can lead to increased production complexity.

The Future of Chemical Raw Materials

As industries evolve, the demand for innovative and sustainable raw materials is on the rise. The focus is shifting towards green chemistry principles that prioritize sustainable sourcing and minimal environmental impact. This includes the exploration of bio-based powders and materials derived from renewable resources.

Moreover, technological advancements are paving the way for improved processing techniques that enhance the efficiency of powder utilization in chemical production. These innovations promise to bolster the capabilities of the chemical industry, ensuring that it can meet the demands of an ever-growing population while adhering to environmentally responsible practices.

Conclusion

In conclusion, powdered raw materials are fundamental to the functionality and growth of the chemical industry. Their unique properties facilitate a variety of applications, driving innovation in countless sectors. By embracing sustainable practices and leveraging technological advancements, the industry can continue to thrive, ensuring that it meets both current and future demands. As we move forward, the commitment to enhancing the quality and safety of these materials will be vital in maintaining the integrity and sustainability of the chemical landscape.