Understanding HPMC Mortars Composition, Applications, and Benefits

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic, water-soluble cellulose ether that has gained significant recognition in the construction industry, particularly in the formulation of mortars. Mortars enhanced with HPMC offer remarkable benefits, leading to their widespread use in various applications including tile adhesives, plastering, and repair mortars. This article delves into the composition, applications, and advantages of HPMC mortars.

Composition of HPMC Mortars

HPMC is synthesized from cellulose through a series of chemical reactions that introduce hydroxypropyl and methyl groups to the cellulose backbone. This modification not only enhances the solubility of cellulose but also improves its properties such as adhesion, viscosity, and film-forming ability. When integrated into mortar formulations, HPMC functions as a thickening agent, enhancing the workability of the mix and providing better control over its properties.

A typical HPMC mortar may consist of several key components, including

1. Cement The primary binding agent, usually Portland cement, which provides structural integrity. 2. Sand Aggregates that contribute to the mortar’s bulk and help achieve desired strength and durability. 3. Water Essential for the hydration process of cement and for achieving proper consistency. 4. HPMC Added in specific ratios to enhance adhesion and improve the rheological behavior of the mortar.

Applications of HPMC Mortars

HPMC mortars are versatile and find use in various construction practices

1. Tile Adhesives HPMC improves the adhesive properties of tile mortars, allowing for better bonding between tiles and substrates, especially in conditions of moisture or high temperature. 2. Plastering When used in plaster mixtures, HPMC enhances the workability and open time, allowing for easier application and manipulation of the plaster before it sets.

3. Repair and Restoration HPMC mortars are commonly employed in repair applications due to their excellent adhesion and flexibility, making them ideal for fixing cracks and surface damage in existing structures.

4. Interior and Exterior Finishes The use of HPMC in finishes provides a smoother surface and improved aesthetics without compromising the strength and durability of the wall systems.

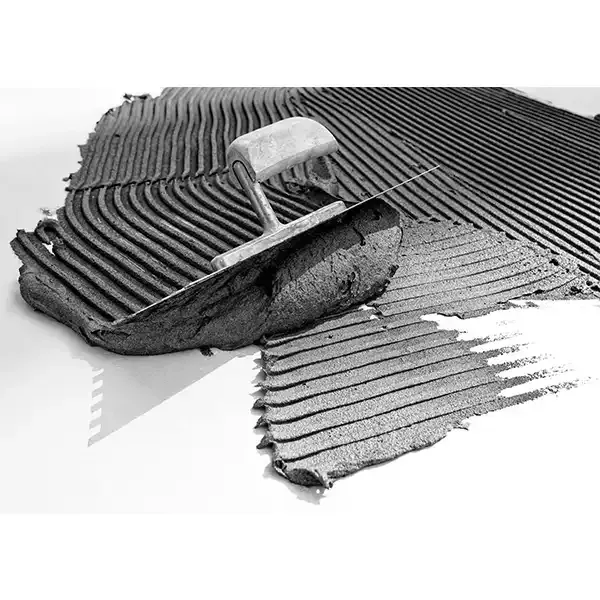

hpmc mortar

5. Dry-Mix Mortars HPMC is especially beneficial in pre-packaged dry-mix mortars, allowing for consistent quality and performance upon mixing with water on-site.

Benefits of HPMC Mortars

The integration of HPMC into mortar formulations brings numerous benefits

1. Enhanced Workability One of the most notable advantages is improved workability, making the mortar easier to mix, apply, and shape. This is especially beneficial for applicators aiming for precision.

2. Increased Adhesion HPMC significantly enhances the adhesive properties of mortars, ensuring strong bonding with various substrates, which is crucial for applications like tiling and plastering.

3. Water Retention HPMC retains water within the mortar, preventing premature drying. This is vital for ensuring proper curing of the cement, leading to enhanced strength and durability.

4. Longer Open Time The use of HPMC allows for a longer working window, providing flexibility for contractors to manage their projects without fearing rapid drying.

5. Versatility HPMC mortars can be utilized in a variety of environmental conditions, including indoor and outdoor applications, making them a go-to choice for various construction needs.

Conclusion

HPMC mortars represent a significant advancement in construction materials, combining the fundamental properties of traditional mortars with innovative enhancements that improve performance, versatility, and usability. As the construction industry continues to demand materials that offer superior performance and reliability, HPMC mortars will likely play an increasingly important role. Whether for tiling, plastering, or repairs, HPMC-enhanced mortars are proving to be a valuable asset in modern construction practices, ensuring durable, high-quality outcomes that meet the needs of both professionals and consumers alike.