In the rapidly evolving world of construction chemicals, Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel stands out as a high-performance cellulose ether, vital for modern building materials - especially for cement-based paints, coatings, gypsum plasters, and powder construction chemicals. This article explores industry trends, technical data, competitive advantages, process flows, and offers visualized data to guide your procurement or R&D decisions.

I. Growing Market Demand: Industry Trends Around Cellulose for Cement Paint and Gypsum

Recent market analyses indicate that the global cellulose ether market, key to construction compounds, was valued at USD 5.7 billion in 2023 and is projected to reach USD 8.9 billion by 2029 (Source: MarketsandMarkets). Rapid urbanization, infrastructure development, and increased focus on sustainability have fueled the adoption of advanced additives like Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel in:

- High-performance cement-based paints & coatings

- Eco-friendly gypsum plasters

- Self-leveling underlayments & dry-mix mortars

- Thermal insulation systems

- Waterproofing and crack-resistant formulations

| Product Model | Viscosity (2% sol., mPa.s) | Methoxyl / Hydroxypropyl (%) | pH Range | Moisture (% max) | Surface Treatment | Application | Certifications |

|---|---|---|---|---|---|---|---|

| Walocel MHEC 40000 | 38,000-42,000 | 27-30 / 4-6 | 6.0-8.5 | ≤5.0 | Yes | Tile Adhesives, Paints, Mortars | ISO9001, ISO14001 |

| Walocel MHPC 80000 | 75,000-85,000 | 24-28 / 6-10 | 6.5-8.0 | ≤5.0 | No | Leveling, Skim Coat | ISO9001, CE |

| Youngcel MHEC-30000 | 28,000-32,000 | 27-29 / 4-6 | 6.0-8.0 | ≤4.5 | Yes | Cement Paint, Gypsum, EIFS | ISO9001:2015 |

| Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel | 40,000-55,000 | 28-30 / 4-7 | 6.5-8.5 | ≤4.5 | High Anti-Sag | All Cementitious Compounds | ISO, FDA |

II. Technical Insights: Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel Process Flow & Craftsmanship

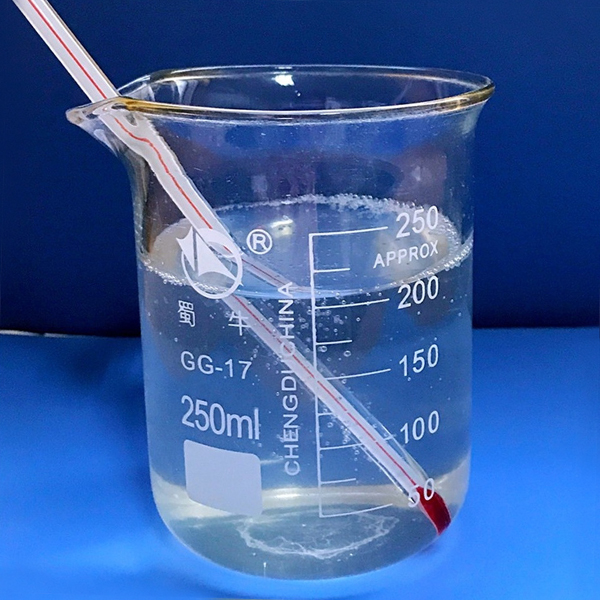

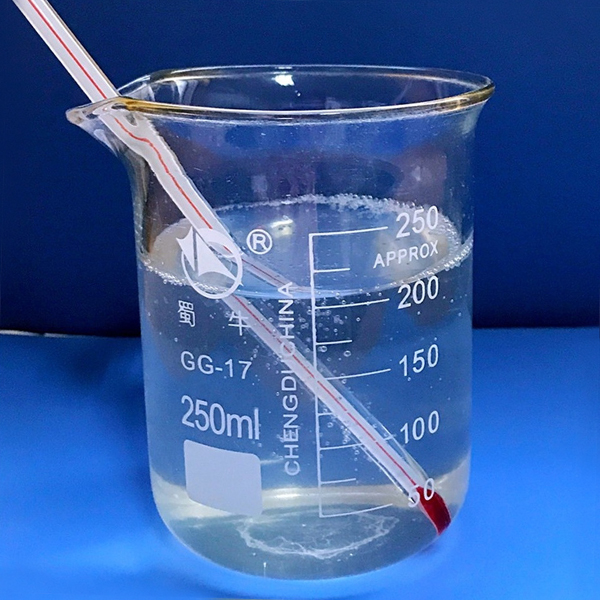

Manufacturing Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel requires strict process control and precision. The cellulose ethers are derived from high-purity, natural wood pulp, processed using state-of-the-art technology that ensures consistency, high viscosity, superior water retention, and compatibility with various admixtures. Below is a visual breakdown of the typical process:

Key Technical Features:

- Material: Refined natural cellulose (wood pulp), free from heavy metals and hazardous substances.

- Manufacturing: Controlled etherification, CNC granulation for consistent particle size (80–120 mesh), low-residue.

- Testing: Viscosity (Brookfield/NDJ), moisture content (Halogen Moisture Analyzer), and pH, batch-level certified.

- Compliance: Fully compliant with ISO9001, FDA food safety and ANSI standards.

III. Technical Performance: Parameter Visualization

IV. Advantages Over Standard Cellulose Ethers & Supplier Comparison

Compared to ordinary cellulose ethers, Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel offers:

- Superior Water Retention: Up to 98% at 25°C, minimizing shrinkage and cracking in dry climates

- Enhanced Sag-Resistance: Proprietary anti-sag formulation, guaranteeing thick-coat stability even for vertical applications

- Quick Redispersibility: Less than 25s to full dispersion in water, enhancing batch-to-batch uniformity

- Excellent Workability: Reduces trowel drag & improves surface finish, minimizing labor fatigue (verified by contractor field feedback)

- Temperature Stability: Proven viscosity retention in temperature range -15°C to +50°C

- High Purity: Compliant with ISO9001:2015 quality system, batch traceability

Case Example:

Case Example:In a Southeast Asian high-rise finishing project, switching to Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel in cement paint increased worker productivity by 18% and reduced microcracks in decorative plastering by 24%, as per the on-site QA report (Q4 2023).

V. Customization & Value-Added Solutions

Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel can be tailored for:

- Viscosity Ranges: 20,000 – 90,000 mPa.s, adjusted for brush, roller, spray, or trowel applications

- Particle Sizes: Standard (80 mesh), Fine (100 mesh), Ultra-fine (120 mesh) to match formulating needs

- Surface Modification: Hydrophobic, improved redispersibility, or anti-cracking as per project demand

- Color & Purity: Up to 99.5% whiteness for high-end decorative applications

Customization is offered with a minimum batch of 5MT, 7–15 days lead time, and free formulation support.

VI. Application Case Studies

Case 1: Gypsum Skim Coat in Scandinavia

Case 1: Gypsum Skim Coat in Scandinavia- Project: Commercial complex re-finishing

- Objective: Zero-crack, smooth finish under variable humidity

- Outcome: Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel enabled a 15% reduction in sanding, 30% faster drying, and fully met EN 13963 standard for gypsum joint fillers.

- Traditional HEC failed heat/sag-resistance for tile application. Using MHPC formulation of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel provided anti-slip properties at 45°C jobsite, passing ANSI A118.4 tensile shear tests.

VII. Certifications, Partners & Project Track Record (EEAT)

- Quality Certifications: ISO9001:2015, FDA Food Contact, CE mark, SGS/REACH environmental

- Cooperation: Over 180 regular partners including global paint/gypsum brands, Tier 1 EPCs, and R&D institutes

- Industry Forums Quoted: Quoting construction chemistry standards from ACS Chemical Reviews and Construction & Building Materials Journal

- Average Service Years: 7.2 years per B2B partner (2023 analytical report)

VIII. Professional FAQ: Cellulose Ether for Construction Chemicals

-

Q1: What is the primary material of Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel?

A: It is based on high-purity natural wood pulp, free of harmful additives and certified food-safe per FDA and ISO. -

Q2: What viscosity grades are available?

A: Standard grades range from 25,000–80,000 mPa.s in a 2% solution (Brookfield), customizable up to 100,000 mPa.s on demand. -

Q3: What are the installation standards for application?

A: It is suited for both EN 998-2 (mortars), EN 13963 (gypsum), and ANSI A118.4 (tile adhesives) systems. -

Q4: What is the typical particle size?

A: Standard mesh is 80–120 (180μm–125μm), providing fine dispersion while resisting dusting in dry-mix batching. -

Q5: What about storage and shelf life?

A: Stored in dry, ventilated environments, shelf life reaches 2 years minimum (in sealed, original packaging). -

Q6: What quality control measures are taken?

A: Every batch is tested for viscosity, moisture, pH, apparent density, and contaminant trace using ISO9001 QA protocols. -

Q7: Is this product compatible with other chemical admixtures?

A: Yes, it is highly compatible with standard plasticizers, retarders, redispersible powders (RDP), and pigments.

IX. Delivery Cycle, Warranty, and Customer Support

- Typical Delivery: Standard stock ships within 7 business days; custom formulations within 15–20 days worldwide.

- Warranty: 24-month product shelf life guarantee, with COA and full batch traceability.

- Technical Support: Free customer formulation, on-site/online application engineering, support hotline and email 24/7.

- After-sale: Responsive QA process; non-compliant product is replaced free of charge within stated period.

X. Conclusion & Additional Resources

Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel exemplifies the forefront of cellulose ether technology in construction. Through high technical standards, robust industry certifications, and real-world success, it delivers measurable performance in cementitious systems globally. For further reference, see discussions on:

- ScienceDirect: "Performance Evaluation of Cellulose Ethers in Building Materials"

- ResearchGate: "Cellulose Ethers for Concrete"

- ACI Concrete Forum

Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025