The Role of Redispersible Polymer Adhesive Powder in the Concrete Industry

In recent years, the concrete industry has witnessed significant advancements, primarily driven by the increasing demand for high-performance building materials. Among these innovations, Redispersible Polymer Adhesive Powder (RDP) has emerged as a crucial component, enhancing the properties of concrete mixtures and applications. This article explores the advantages and applications of RDP in the concrete sector.

What is Redispersible Polymer Adhesive Powder?

Redispersible Polymer Adhesive Powder is a dry powder that, when mixed with water, forms a uniform emulsion of polymers. It is derived from various monomers and is designed to improve bonding, flexibility, and durability of cementitious materials. This versatile powder is widely used in various applications, such as tile adhesives, renderings, repair mortars, and self-leveling compounds.

Advantages of RDP in Concrete Applications

1. Enhanced Bonding Strength RDP significantly improves the adhesion of the cement matrix to various substrates, ensuring a robust bond between the layers. This enhanced bonding is vital for applications such as tile laying, where a strong attachment prevents delamination.

2. Flexibility and Elasticity One of the standout properties of RDP is its ability to impart flexibility to concrete. Traditional cement-based materials can be prone to cracking under stress. The addition of RDP allows for minor movements within the structure without compromising the integrity of the concrete, making it ideal for dynamic environments.

3. Improved Workability RDP contributes to better workability of concrete mixtures. It enhances the ease of application, allowing for smoother finishes and improved handling during construction. This is particularly beneficial in projects requiring intricate detailing or precision.

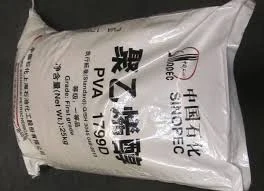

redispersible polymer adhesive powder rdp used in concrete industry

4. Water Resistance Incorporating RDP into concrete formulations can lead to improved water resistance. This attribute is crucial for exterior applications, such as facades and pavements, where exposure to moisture can lead to rapid deterioration of traditional concrete.

5. Resistance to Chemical Attack RDP enhances the chemical resistance of concrete, making it suitable for environments where exposure to aggressive substances is a concern. This is particularly valuable in industrial settings or in areas that come into contact with detergents, acids, and other detrimental agents.

Applications in the Concrete Industry

Redispersible Polymer Adhesive Powder finds its application across various segments of the concrete industry. One of the most common uses is in tile adhesives, where it ensures strong adhesion between tiles and substrate while providing flexibility to accommodate movements. In renderings, RDP helps achieve a durable finish with excellent resistance to weathering.

Moreover, RDP is instrumental in repair mortars, where it aids in restoring the integrity of damaged structures. In self-leveling compounds, RDP enhances flow properties, leading to a smooth and level surface, essential for flooring applications.

Conclusion

The incorporation of Redispersible Polymer Adhesive Powder in concrete mixtures marks a significant step towards improving the performance and longevity of construction materials. Its ability to enhance bonding strength, flexibility, workability, and resistance to various environmental factors makes it an invaluable asset in the concrete industry. As the demand for high-performance building materials continues to grow, RDP will undoubtedly play a pivotal role in shaping the future of concrete applications. Embracing such innovations is essential for achieving sustainability and efficiency in construction practices.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025