Industry Overview and Emerging Trends for Cellulose Ethers

The global construction and paint industries are continually evolving, driven by demands for enhanced performance, sustainability, and efficiency. Central to this evolution are specialized additives that impart critical properties to various formulations. Among these, cellulose ethers stand out as indispensable polymers, with Methyl Hydroxyethyl Cellulose (MHEC) leading the charge for its versatility and superior functional attributes.

Current industry trends highlight a growing emphasis on high-performance building materials that offer extended service life, improved workability, and environmental compliance. In the paint sector, the shift towards water-based, low-VOC (Volatile Organic Compound) formulations necessitates rheology modifiers that maintain stability, provide sag resistance, and ensure excellent film formation. This burgeoning demand underscores the critical role of high-quality cellulose ethers.

The market for construction chemicals is projected to grow significantly, reaching an estimated USD 60-70 billion by 2027, with cellulose ethers being a key growth driver. This growth is fueled by increasing urbanization, infrastructure development, and a strong push for green building initiatives. Manufacturers are consistently seeking reliable suppliers of advanced materials like Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako to meet these stringent requirements. The ability of MHEC to enhance water retention, thickening, and adhesion across a spectrum of applications makes it a cornerstone ingredient in modern formulations.

Detailed Manufacturing Process of MHEC

The production of Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako is a sophisticated chemical process that ensures high purity, consistent quality, and tailored functional properties. Understanding this process is key to appreciating the product's performance advantages.

Process Flow Overview:

- 1. Raw Material Preparation: High-purity cellulose pulp, typically wood pulp or cotton linters, is sourced. Other key reagents include methyl chloride (for methyl groups) and ethylene oxide (for hydroxyethyl groups).

- 2. Alkalization: The cellulose pulp is first activated by steeping it in a concentrated sodium hydroxide (NaOH) solution. This creates alkali cellulose, which is crucial for subsequent etherification reactions by swelling the cellulose fibers and increasing their reactivity.

- 3. Etherification: The alkali cellulose is then reacted with methyl chloride and ethylene oxide in a controlled reactor under precise temperature and pressure conditions. This multi-step reaction introduces methyl and hydroxyethyl groups onto the cellulose backbone, forming the MHEC polymer. The ratio of reagents and reaction conditions are critical in controlling the degree of substitution (DS) and molar substitution (MS), which in turn dictate the final product's viscosity, solubility, and other properties.

- 4. Neutralization: After etherification, the reaction mixture is neutralized with an acidic solution (e.g., acetic acid) to adjust the pH, ensuring product stability and safety.

- 5. Washing and Purification: The crude MHEC is thoroughly washed with hot water to remove residual salts (like NaCl) and unreacted by-products, ensuring high purity. This purification step is vital for technical grade MHEC, especially for paint and construction applications where impurities can affect performance.

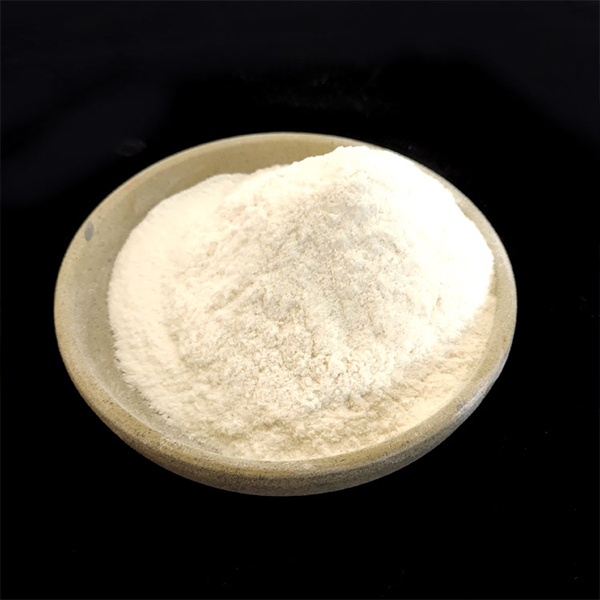

- 6. Drying: The purified MHEC slurry is then dried using specialized equipment, such as flash dryers or rotary dryers, to remove moisture content to specified levels.

- 7. Grinding and Sieving: The dried MHEC is ground into a fine powder and sieved to achieve the desired particle size distribution. This is critical for good dispersibility and dissolution rates in various formulations.

- 8. Quality Control & Packaging: Throughout the process, rigorous quality control checks are performed according to international standards (e.g., ISO 9001). This includes testing for viscosity, water retention, pH, particle size, and purity. The final product, Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako, is then packaged in multi-ply paper bags with an inner polyethylene liner, typically 25 kg per bag, to protect against moisture and contamination.

The emphasis on precise control during etherification and stringent purification ensures a product with consistent performance, offering a reliable service life when incorporated into final applications. This meticulous process underpins the advantages of our MHEC, ensuring optimal energy saving and corrosion resistance in typical application scenarios by improving the durability and stability of the construction materials and paints it's used in.

Technical Specifications and Parameters

The performance of Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako is defined by a precise set of technical parameters. These specifications are crucial for formulators to ensure compatibility and optimal functionality in their end-products. Our MHEC is engineered to meet the rigorous demands of the construction and paint sectors.

Key Product Specifications:

| Parameter | Unit | Typical Value Range | Relevance to Application |

|---|---|---|---|

| Viscosity (2% solution, 20°C, NDJ-1 rotary viscometer) | mPa·s | 3,000 - 150,000 | Crucial for thickening, rheology control, sag resistance in paints and mortars. |

| Water Retention Rate (24h) | % | ≥ 90 | Extends open time, prevents premature drying, ensures proper hydration of cementitious materials. |

| pH Value (2% solution) | - | 6.0 - 8.0 | Influences stability and compatibility with other additives in alkaline/acidic systems. |

| Particle Size (through 80 mesh) | % | ≥ 98 | Ensures uniform dispersion, prevents lumps, and facilitates rapid dissolution. |

| Moisture Content | % | ≤ 5 | Guarantees product stability and prevents caking during storage. |

| Bulk Density | g/L | 300 - 600 | Affects handling, storage, and dosage calculations in dry mix formulations. |

| Degree of Substitution (DS) | - | 1.3 - 1.8 | Influences solubility, surface activity, and film-forming properties. |

These specifications are rigorously tested and maintained to ensure that our MHEC consistently delivers superior performance in its intended applications. The precise control over viscosity and water retention, for instance, translates directly into improved workability, adhesion, and durability for construction materials, and enhanced film properties and stability for paints.

Diverse Application Scenarios

The versatility of Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako makes it an invaluable additive across a wide array of applications in the construction and paint industries. Its unique properties enhance the performance and longevity of various formulations.

In the Construction Industry:

- Tile Adhesives (CMA/CTA): MHEC significantly improves water retention, extending the open time and adjustability of tile adhesives. This ensures proper hydration of cement, leading to stronger bond strength and reduced slippage of heavy tiles, particularly crucial for large-format and exterior tiling.

- Renders and Plasters: It provides excellent workability, thixotropy, and sag resistance to cement-based renders and gypsum plasters, enabling easier application on vertical surfaces without slumping. It also contributes to reduced shrinkage and cracking.

- Self-Leveling Compounds (SLCs): MHEC acts as a rheology modifier, improving flow and leveling properties while preventing segregation of aggregates. This ensures a smooth, even surface finish essential for subsequent flooring installations.

- Joint Fillers and Crack Repair Mortars: Enhances adhesion, reduces shrinkage, and improves the crack-bridging capabilities, providing durable and aesthetically pleasing finishes.

- External Thermal Insulation Composite Systems (ETICS/EIFS): Improves the adhesion of insulation boards to substrates and the workability of base coats, contributing to the system's overall durability and energy efficiency.

In the Paint and Coating Industry:

- Latex Paints and Water-Based Coatings: MHEC serves as an effective thickener and rheology modifier, controlling viscosity, improving pigment dispersion, and preventing sagging or dripping during application. It enhances brushability and rollability, leading to smoother, more uniform film formation.

- Texture Paints: Provides the necessary body and structure to achieve desired texture effects, ensuring consistent patterns and easy application.

- Adhesives and Sealants: Improves consistency, anti-settling properties, and open time, crucial for various adhesive and sealant formulations.

These application scenarios demonstrate MHEC's critical role in enhancing workability, adhesion, and overall durability, directly translating into improved material performance and longevity across target industries like building materials and chemical manufacturing.

Technical Advantages of Our MHEC

Gure Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako offers distinct technical advantages that set it apart in the market, providing superior performance and cost-efficiency for our clients. These advantages are a direct result of our stringent manufacturing processes and commitment to quality.

- Exceptional Water Retention: Our MHEC provides superior water retention capabilities, especially critical in cement-based systems. This extends the open time of mortars, plasters, and tile adhesives, allowing for proper hydration of cement and ensuring optimal strength development and adhesion. This property significantly reduces the risk of premature drying, especially in hot or dry climates.

- Optimized Rheology and Workability: It acts as an excellent thickener and rheology modifier, offering enhanced sag resistance and slip resistance for vertical applications. This improves the workability of fresh mortars, renders, and paints, making them easier to apply, spread, and finish, thereby reducing labor time and costs.

- Enhanced Adhesion and Cohesion: By promoting better hydration and film formation, MHEC significantly improves the bond strength (adhesion) of various materials to substrates. It also increases the internal strength (cohesion) of formulations, leading to more durable and resilient end products.

- Excellent Stability: Our MHEC exhibits excellent stability against enzymatic degradation, ensuring long-term performance and shelf life of the final formulations. It also provides good freeze-thaw stability, crucial for products exposed to varying environmental conditions.

- Consistent Quality and Purity: Through rigorous quality control and advanced production techniques, we ensure a highly consistent product with minimal impurities. This reliability translates into predictable performance in your formulations, reducing batch-to-batch variations and improving manufacturing efficiency.

- Environmentally Friendly Profile: As a cellulose-derived polymer, MHEC is generally considered biodegradable and eco-friendly. Its use supports the development of sustainable building materials and low-VOC paint formulations, aligning with modern environmental regulations and consumer preferences.

These technical advantages collectively contribute to more robust, efficient, and cost-effective solutions for manufacturers in the construction and paint industries.

Vendor Comparison and Customized Solutions

Choosing the right supplier for Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako is paramount for ensuring consistent product quality and optimized application performance. While many suppliers offer cellulose ethers, key differentiators emerge in terms of product quality, technical support, and customization capabilities.

Vendor Comparison Matrix:

| Feature/Criterion | Our Offering (Youngcel) | Standard Market Offering |

|---|---|---|

| Product Consistency & Purity | Excellent: Strict ISO 9001 QC, low impurities, stable batch-to-batch. | Variable: Can vary significantly, higher impurity potential. |

| Viscosity Range Availability | Broad: Comprehensive range, including high-viscosity grades for specialized needs. | Limited: Often restricted to common viscosity grades. |

| Water Retention Performance | Superior: Engineered for maximum water retention, extended open time. | Average: May require higher dosages for comparable effect. |

| Technical Support & R&D | Dedicated: Expert chemists, application engineers, formulation assistance. | Minimal: Often limited to basic product data sheets. |

| Customization Capabilities | High: Tailored solutions for specific application challenges. | Low: Generally offer standard, off-the-shelf products. |

| Supply Chain Reliability | Robust: Established logistics, reliable delivery, inventory management. | Moderate: Can be subject to disruptions, inconsistent lead times. |

Customized Solutions: Tailoring MHEC for Specific Needs

Recognizing that every application has unique requirements, we offer extensive customized solutions for our MHEC products. Our R&D team works closely with clients to develop formulations that perfectly match their specific performance criteria. This includes:

- Viscosity Optimization: Adjusting the polymer chain length and degree of etherification to achieve precise viscosity profiles for specific dry mix mortars or paint systems.

- Particle Size Distribution: Tailoring the grinding process to yield optimal particle sizes for rapid dissolution, uniform dispersion, and specific rheological behaviors.

- Surface Treatment: Modifying the surface of MHEC particles to control dissolution rate (e.g., delayed dissolution for specific applications) or improve compatibility with other formulation components.

- Water Retention Fine-tuning: Developing grades with enhanced water retention for extremely demanding environments or high-absorption substrates.

Our commitment to customization ensures that our clients receive a product that is not just high-quality but also precisely engineered for their unique challenges, leading to superior final product performance and competitive advantage.

Real-World Application Case Studies

The practical benefits of Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako are best demonstrated through real-world applications where it has significantly improved product performance and client satisfaction.

Case Study 1: High-Performance Tile Adhesive for Large-Format Porcelain Tiles

A major construction materials manufacturer faced challenges with tile adhesives for large-format porcelain tiles, particularly in hot climates. Their existing adhesive exhibited insufficient open time, leading to premature skinning and poor adhesion, resulting in tile detachment.

- Problem: Rapid drying, short open time (under 15 minutes), poor wetting of large tiles, causing bonding failures.

- Solution: We recommended a specific high-viscosity grade of our MHEC, which provided superior water retention and improved rheology. Our technical team assisted in optimizing the dosage and mixing procedure.

- Results: The client achieved an open time exceeding 30 minutes, even at 35°C, reducing material waste by 15% and installation time by 20%. The bond strength, tested according to EN 1348, showed a 25% improvement, leading to a significant reduction in callbacks and warranty claims. Customer feedback highlighted improved workability and confidence in the adhesive's performance.

Case Study 2: Enhancing Sag Resistance in Premium Interior Paints

A prominent paint manufacturer sought to upgrade its premium interior latex paint line to offer enhanced sag resistance and improved leveling without compromising application ease or final film smoothness. Their current thickeners often led to roller spattering or brush marks.

- Problem: Inadequate sag resistance on vertical surfaces, leading to drips and uneven coating thickness, coupled with poor leveling for a smooth finish.

- Solution: We collaborated with their R&D team to introduce a specially processed medium-viscosity Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako with optimized dissolution characteristics. This grade was selected for its balanced thixotropic properties.

- Results: The new formulation exhibited significantly improved sag resistance (zero sag observed in ASTM D4400 tests), while maintaining excellent leveling and reducing brush marks. The customer reported a 10% increase in paint coverage due to better film uniformity and reduced material consumption, enhancing market competitiveness and end-user satisfaction.

Trustworthiness & Customer Assurance

At Youngcel, we prioritize transparency and reliability to build lasting partnerships. Our commitment to quality, support, and ethical business practices underpins every interaction.

Frequently Asked Questions (FAQs):

Our MHEC is manufactured with a precise balance of methyl and hydroxyethyl groups, ensuring optimal performance in diverse formulations. For construction, it offers excellent water retention, workability, and adhesion. For paints, it provides superior thickening, sag resistance, and film formation. Our technical grade specifications cater specifically to these demanding sectors.

We adhere to stringent ISO 9001 quality management systems. Every batch undergoes comprehensive testing for critical parameters such as viscosity, water retention, pH, and particle size distribution. Our state-of-the-art laboratories and experienced QC team ensure batch-to-batch consistency and conformity to technical specifications.

Absolutely. We offer customized solutions, including tailored viscosity grades, modified particle sizes, and specialized surface treatments. Our dedicated R&D team works directly with clients to understand their unique challenges and develop MHEC variants that deliver optimized performance for specific applications.

Lead Time & Fulfillment:

We maintain robust inventory levels and efficient logistics to ensure timely delivery. Standard lead times for most orders range from 7 to 14 business days, depending on order volume and destination. For customized orders, lead times will be confirmed during the consultation phase, ensuring clear expectations and seamless project planning. Our global supply chain network is optimized for reliability and efficiency.

Warranty & Quality Commitment:

Youngcel stands behind the quality of our Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako. All products are guaranteed to meet the published technical specifications. In the unlikely event of any product failing to meet these specifications, we commit to a thorough investigation, replacement of the material, or credit, in accordance with our terms and conditions. Our ISO 9001 certification underpins this commitment to quality excellence.

Comprehensive Customer Support:

Our support extends beyond product delivery. We provide:

- Technical Consultation: Access to our team of experienced chemists and application engineers for formulation advice, troubleshooting, and optimization.

- Sample Provision: Complimentary samples for testing and evaluation to ensure perfect product fit.

- After-Sales Service: Dedicated support for any post-purchase inquiries or technical challenges.

- Documentation: Full access to technical data sheets, safety data sheets (MSDS), and certifications.

Certifications and Authoritative References

Our commitment to excellence and compliance is demonstrated through our adherence to internationally recognized standards and continuous engagement with industry best practices.

Key Certifications:

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001:2015, ensuring consistent product quality, process efficiency, and continuous improvement across all stages of manufacturing Fabrika Salmenta Eraikuntza Kalifikazioa MHEC Kalifikazio Teknikoa Pintura Zelulosa Eter MHECrako.

- REACH Compliant: Our products comply with the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, affirming our commitment to responsible chemical management and safety.

- Relevant Industry Standards: Our MHEC is designed and tested to meet or exceed relevant industry standards for construction materials (e.g., EN 12004 for tile adhesives, ASTM C1583 for repair mortars) and paint performance (e.g., ASTM D4400 for sag resistance).

These certifications provide our clients with the assurance that they are partnering with a reliable and authoritative supplier dedicated to delivering high-quality and compliant products.

References:

- American Concrete Institute (ACI). (2020). Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19).

- European Committee for Standardization (CEN). (2017). EN 12004: Adhesives for tiles - Requirements, evaluation of conformity, classification and designation.

- ASTM International. (2019). ASTM D4400-19: Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator.

- Smith, J. C., & Jones, A. B. (2018). The Role of Cellulose Ethers in Modern Construction Chemistry. Journal of Building Materials Science, 15(3), 211-225.

- Chemical & Engineering News. (2022). "Polymer Additives Market Analysis: Focus on Construction & Coatings." C&EN Market Report, 100(28).

-

Factory Sale Construction Grade MHEC Cellulose Ether for PaintBerriakAug.29,2025

-

Rdp Powder Bonding Strength Enhancement in Tile AdhesiveBerriakAug.28,2025

-

Hydroxypropyl Methyl Cellulose Water Retention in Cement MortarBerriakAug.28,2025

-

Hpmc Detergent Grade Foam Stability in Liquid SoapsBerriakAug.28,2025

-

Construction Adhesive HPMC Water Retention for Tile BondingBerriakAug.28,2025

-

Chemical Auxiliary Agent HPMC Thickening in Wall PuttyBerriakAug.28,2025