Chemicals for Making Cement A Comprehensive Overview

Cement is one of the most widely used construction materials globally, forming the backbone of various infrastructures, including buildings, bridges, and roads. It is essential to understand the chemicals involved in the production of cement, as they play a critical role in defining the properties and performance of the final product. This article explores the primary chemicals used in cement manufacturing, their functions, and the chemistry behind the cement hydration process.

The Primary Components of Cement

The primary raw materials used in the manufacture of cement include limestone, clay, and gypsum. These materials are rich in specific compounds that are essential for cement production.

1. Limestone Composed mainly of calcium carbonate (CaCO3), limestone is the primary source of calcium in cement. When heated to high temperatures in a kiln (approximately 1450°C), limestone undergoes a chemical transformation to produce lime (calcium oxide, CaO) and carbon dioxide (CO2).

2. Clay Clay minerals contribute silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3) to the cement mix. The presence of alumina is crucial, as it combines with lime to form dicalcium silicate, a major component that imparts strength to cement.

3. Gypsum Upon the completion of the clinker stage, gypsum (calcium sulfate dihydrate, CaSO4·2H2O) is added to the cement to regulate the setting time. The addition of gypsum prevents the premature hardening of cement when mixed with water.

Key Chemical Compounds in Cement

The main compounds that result from the calcination of limestone and clay in the production of cement include

1. Tricalcium Silicate (C3S) This compound plays a vital role in the early strength development of cement. Its hydration, which occurs when the cement is mixed with water, produces calcium silicate hydrate (C-S-H) and calcium hydroxide (CH). C-S-H is responsible for providing strength, making C3S a key component of Portland cement.

2. Dicalcium Silicate (C2S) Contributing to the strength of cement over time, C2S hydrates more slowly than C3S and improves the long-term strength of the concrete.

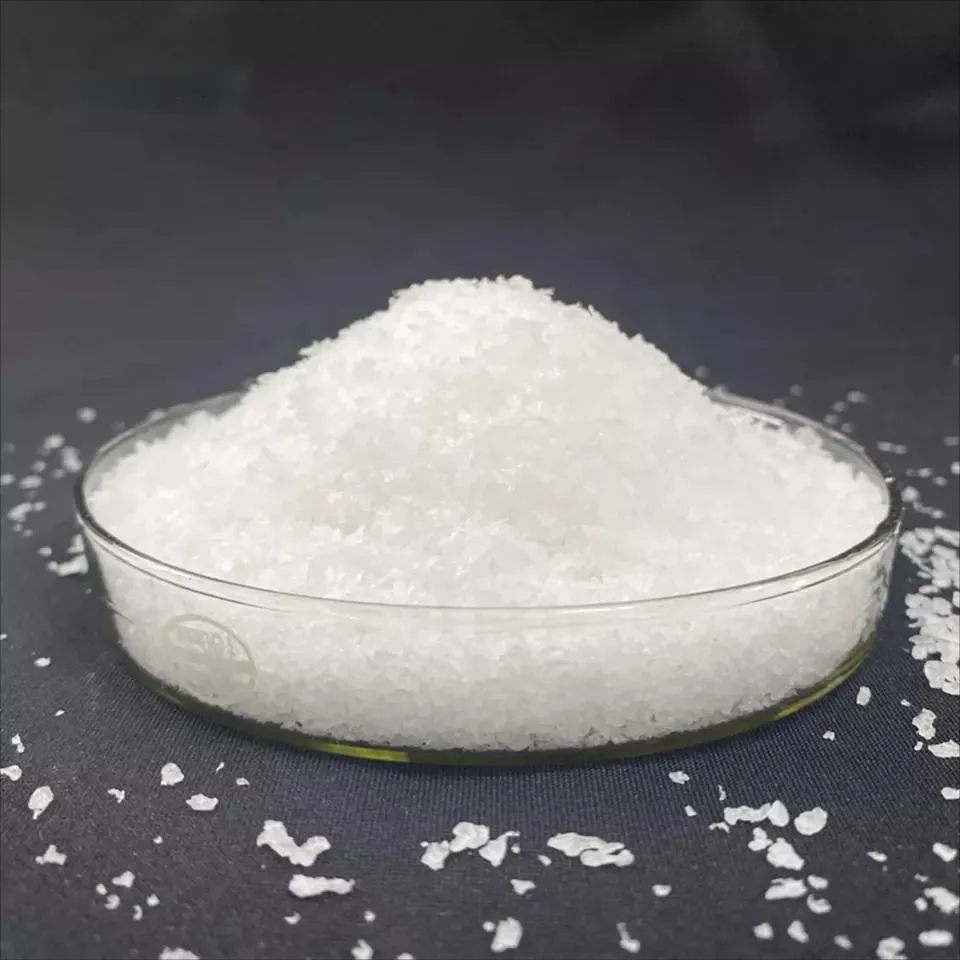

chemicals for making cement

3. Tricalcium Aluminate (C3A) This compound is crucial for the initial setting of cement. Its hydration releases a significant amount of heat, an effect known as heat of hydration, which can be beneficial in some construction scenarios. However, excess C3A can lead to rapid setting, which is why gypsum is added to moderate this reaction.

4. Tetracalcium Aluminoferrite (C4AF) This compound contributes to the color of the cement and can enhance the workability of concrete. It helps to reduce the overall cost of cement production as it can substitute for higher-cost materials.

The Hydration Process

Upon mixing cement with water, a series of complex chemical reactions known as hydration occurs, leading to the hardening of the cement. The main reactions involve the dissolution of C3S and C2S, resulting in the formation of C-S-H and CH. This process not only binds the aggregates (sand and gravel) but also creates a dense matrix that provides the required strength and durability.

1. C3S hydration This occurs quickly, generating significant strength within the first few days. \[ C_3S + H_2O \rightarrow C-S-H + CH \]

2. C2S hydration This takes longer, contributing to strength gain over weeks and months. \[ C_2S + H_2O \rightarrow C-S-H + CH \]

3. C3A hydration Reacts with gypsum to form ettringite, a compound that contributes to the early setting and strength. \[ C_3A + 3CH + 32H \rightarrow C_6A·3H_32 \]

The careful control of these chemical processes is essential. Variation in the proportion of these compounds can lead to significant differences in performance characteristics like strength development, setting time, and resistance to environmental conditions.

Conclusion

An understanding of the chemicals involved in cement production is crucial for optimizing the manufacturing process and ensuring the quality of concrete. The interaction of various components and their roles during hydration are fundamental to producing cement with desired characteristics. As the construction industry continues to evolve, innovations in cement chemistry will play a pivotal role in enhancing sustainability and reducing the environmental impact of cement production.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025