The Future of Tile Manufacturing HPMC as an Essential Component

As the demand for high-quality, durable, and aesthetically pleasing tiles continues to rise in the construction and interior design industries, manufacturers are continually seeking innovative materials that can enhance the properties of tile adhesives and grouts. One such material that has garnered significant attention is Hydroxypropyl Methylcellulose (HPMC). This cellulose ether is widely regarded for its unique properties that improve the performance of tile adhesives, making it a crucial component in modern tile manufacturing.

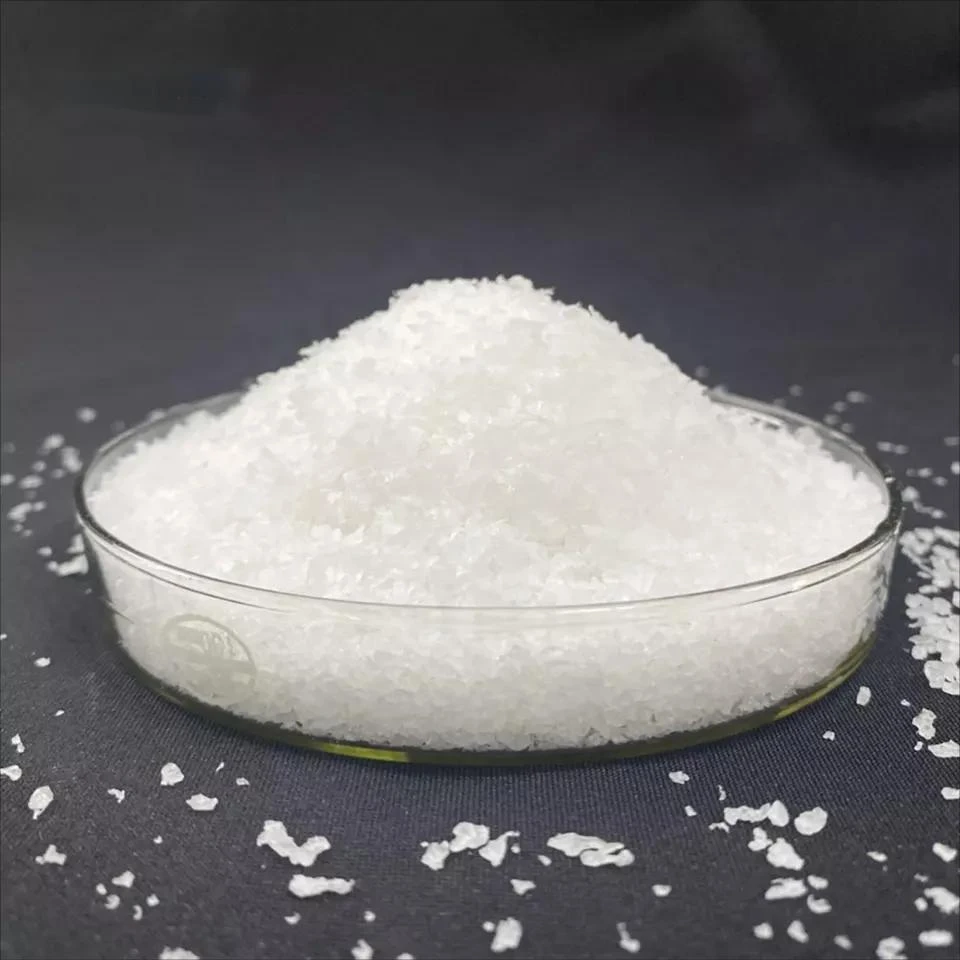

Understanding HPMC

HPMC is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer found in the cell walls of plants. It is characterized by its ability to form gels and thick solutions, making it an invaluable additive in various applications. In the realm of tile manufacturing, HPMC serves multiple purposes, including enhancing the workability, adhesion, and water retention of tile adhesives and grouts.

One of the key benefits of HPMC is its rheological properties. By modifying the viscosity of tile adhesives, HPMC ensures that the mixtures are easy to apply without compromising their stability. This feature is particularly important for large-format tiles and those with intricate designs that require precise placement. Tile installers find it easier to work with adhesives that remain smoothly spreadable and have a consistent texture, reducing the likelihood of uneven application that can lead to tiling errors.

Improved Adhesion and Bond Strength

The adhesion properties of tile adhesives are critical for ensuring that tiles remain securely affixed to surfaces over time. HPMC enhances the adhesive strength of tile mortars by improving the interfacial bonding between the adhesive and the tile substrate. This is crucial for both residential and commercial applications, where the durability of tiled surfaces is paramount.

Moreover, HPMC's water-retention capabilities play a significant role in the curing process of tile adhesives. By retaining moisture, HPMC ensures that the adhesive has the necessary hydration to fully cure and bond effectively. This is especially important in hot and dry climates, where rapid evaporation can undermine the adhesion process and lead to tile failure. The addition of HPMC minimizes this risk, enabling a stronger and more reliable bond.

hpmc for tile

Versatility Across Various Applications

HPMC is not limited to just one type of tile adhesive; its versatility allows it to be utilized in various formulations, including those designed for ceramics, porcelain, natural stone, and even large-format tiles. As the trend toward larger tiles continues to grow, the demand for high-performance adhesives that can accommodate their weight and size has never been greater. HPMC is integral to these formulations, offering solutions that meet the diverse needs of tile manufacturers and installers alike.

Additionally, HPMC is often employed in combination with other additives and polymers to optimize specific performance characteristics. For instance, when combined with other cellulose ethers, HPMC can enhance the open time of adhesives, allowing for longer working periods before the adhesive begins to set. This is particularly beneficial for complex projects that require more time for tile placement and adjustments.

Environmental Considerations

In today’s environmentally conscious market, the use of sustainable materials in construction is a growing trend. HPMC is derived from natural cellulose, making it a preferable option for manufacturers looking to reduce their environmental footprint. Furthermore, many HPMC products are produced through processes aimed at minimizing waste and reducing energy consumption, aligning with the broader goals of sustainability within the industry.

Conclusion

As the tile industry evolves, the role of additives such as HPMC becomes increasingly critical. From enhancing adhesion and workability to improving water retention and sustainability, HPMC is a multifaceted component that meets the demands of modern tile manufacturing. As manufacturers continue to innovate and adapt to changing market needs, HPMC is poised to remain at the forefront of the tile adhesive landscape, driving quality and performance to new heights. With its numerous benefits and versatility, HPMC is more than just an additive; it is an essential ingredient in creating the durable, beautiful tiled surfaces that define contemporary architecture and design.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025