Understanding HPMC Manufacturing Processes, Applications, and Innovations

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used non-ionic cellulose ether derived from natural cellulose. Its unique properties make it an essential component in various industries, including pharmaceuticals, food, construction, and cosmetics. This article delves into the manufacturing processes of HPMC, its diverse applications, and recent innovations shaping the future of the industry.

The Manufacturing Process of HPMC

The manufacturing of HPMC involves a few critical steps that transform cellulose into this functional polymer. The process begins with the sourcing of cellulose, which can be derived from wood pulp or cotton. The cellulose is then treated with a series of chemical processes that include etherification, hydrolysis, and purification.

1. Etherification In this step, cellulose is reacted with propylene oxide and methyl chloride in an alkaline environment. This reaction introduces hydroxypropyl and methyl groups into the cellulose structure, forming HPMC. The degree of substitution of these groups affects the properties of the final product, influencing its solubility and viscosity.

2. Purification The crude HPMC is subsequently purified to remove unreacted ingredients, residual solvents, and other impurities. This purification step is crucial to ensure the quality and safety of HPMC, especially for applications in pharmaceuticals and food.

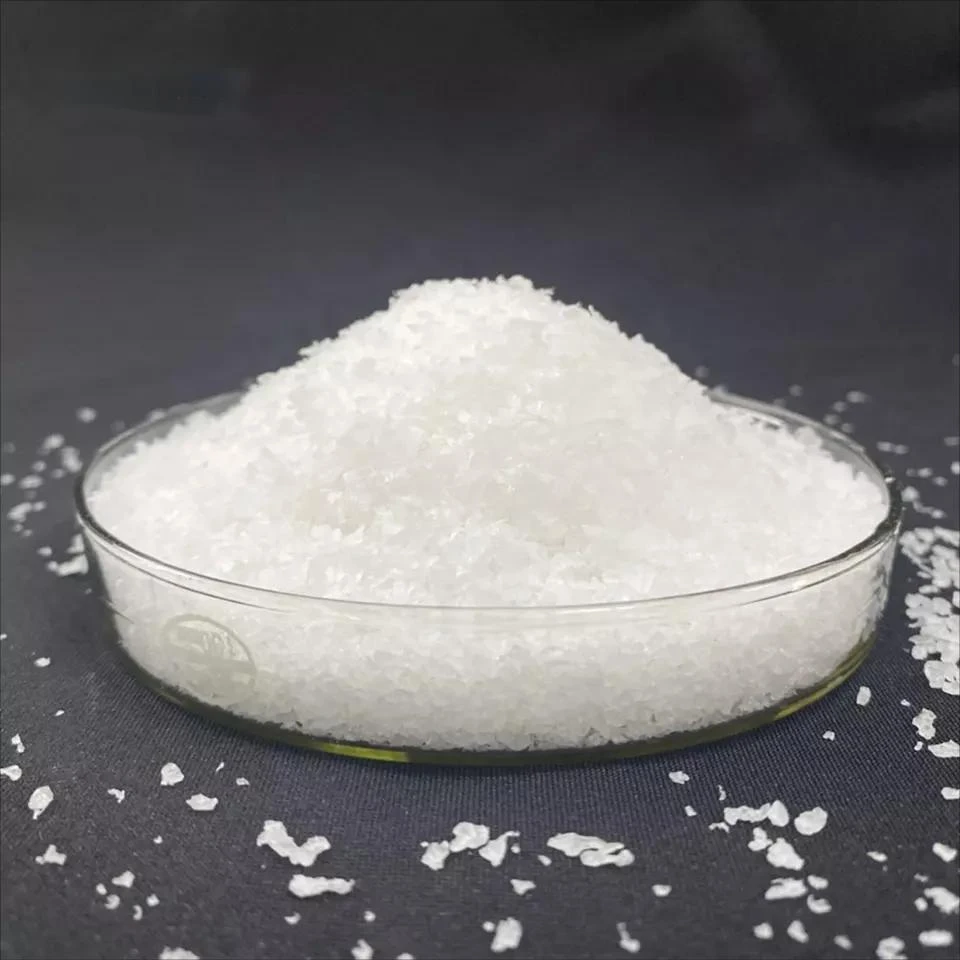

3. Drying and Milling The purified HPMC is dried and milled into a fine powder. The particle size can be adjusted depending on the desired application, ensuring optimal performance in various formulations.

4. Quality Control Rigorous quality control measures, including testing for viscosity, moisture content, and purity, are essential to meet industry standards and specifications. Manufacturers often adhere to Good Manufacturing Practices (GMP) to ensure product safety and efficacy.

Applications of HPMC

HPMC is celebrated for its multifunctional properties, which include thickening, binding, film-forming, and water-retention capabilities. Its applications span several industries

hpmc manufactur

- Pharmaceuticals In the pharmaceutical sector, HPMC is used as a binder and a controlled-release agent in tablets and capsules. Its ability to form gels and provide extended-release formulations makes it ideal for various medicinal products.

- Food HPMC acts as a thickening agent, stabilizer, and emulsifier in food products. It enhances the texture and consistency of sauces, ice creams, and salad dressings while improving shelf life.

- Construction In the construction industry, HPMC is incorporated into dry mix mortars and plasters. It improves workability, enhances adhesion, and controls water retention, making it a vital ingredient in construction materials.

- Cosmetics In personal care products, HPMC serves as a thickener and stabilizer in lotions, creams, and gels. It helps maintain the desired viscosity and texture, ensuring a pleasant user experience.

Innovations in HPMC Production

Recent developments in HPMC manufacturing are focused on sustainability and efficiency. Manufacturers are exploring the use of renewable resources and environmentally friendly processes to produce HPMC. Innovations in technology, such as advanced enzymatic processes, are being researched to enhance the efficiency of cellulose conversion, thereby reducing waste and energy consumption.

Furthermore, advancements in quality control technologies, such as real-time monitoring and AI-based systems, are optimizing the production process. These innovations ensure consistent product quality and facilitate rapid response to market demands.

Conclusion

HPMC is a prime example of how a natural polymer can be transformed into a multifunctional ingredient used across various industries. Understanding its manufacturing process, diverse applications, and ongoing innovations highlights the importance of HPMC in modern technology and daily life. As the demand for sustainable and high-performance materials grows, the future of HPMC manufacturing promises to contribute significantly to various sectors, enhancing product quality and functionality while adhering to environmental standards.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025