The Future of HPMC Manufacturing Plants

Hydroxypropyl Methylcellulose (HPMC) is a popular cellulose ether that has a wide range of applications in various industries, including pharmaceuticals, food, construction, and personal care. As demand for HPMC continues to rise due to its versatility and functional properties, the establishment and operation of HPMC manufacturing plants have become increasingly important. This article explores the significance of HPMC manufacturing plants, their operational processes, challenges, and future prospects.

Significance of HPMC

HPMC is a non-ionic cellulose ether derived from natural polymer cellulose, and it is valued for its ability to form films, enhance viscosity, and improve texture. In the pharmaceutical industry, HPMC is widely used as a tablet binder and coating agent, and it plays a crucial role in controlled-release formulations. In the food sector, it is utilized as a food additive to improve texture and stability, while in construction, HPMC is combined with cement to enhance the workability of mortars and plasters.

Given its diverse applications, the global market for HPMC is expanding rapidly

. This growth has led to an increased number of HPMC manufacturing plants, which are strategically located to meet local and international demand.Operational Processes

The manufacturing of HPMC involves several key steps. Initially, cellulose sourced from wood pulp or cotton is chemically treated to produce cellulose ether. The bulk of the process includes etherification, where hydroxypropyl and methyl groups are introduced to produce the desired HPMC compound.

Quality control is of utmost importance in HPMC manufacturing to ensure the consistency and effectiveness of the final product. Laboratories equipped with advanced analytical techniques, such as high-performance liquid chromatography (HPLC) and nuclear magnetic resonance (NMR) spectroscopy, are instrumental in monitoring the product's purity, viscosity, and molecular weight. These measures ensure that the HPMC produced can meet the specific needs of different industries.

Moreover, the manufacturing plants are equipped with modern technology that allows for continuous production, leading to efficiency and cost-effectiveness. Automation plays a significant role in minimizing human error and optimizing resource utilization, enhancing overall productivity.

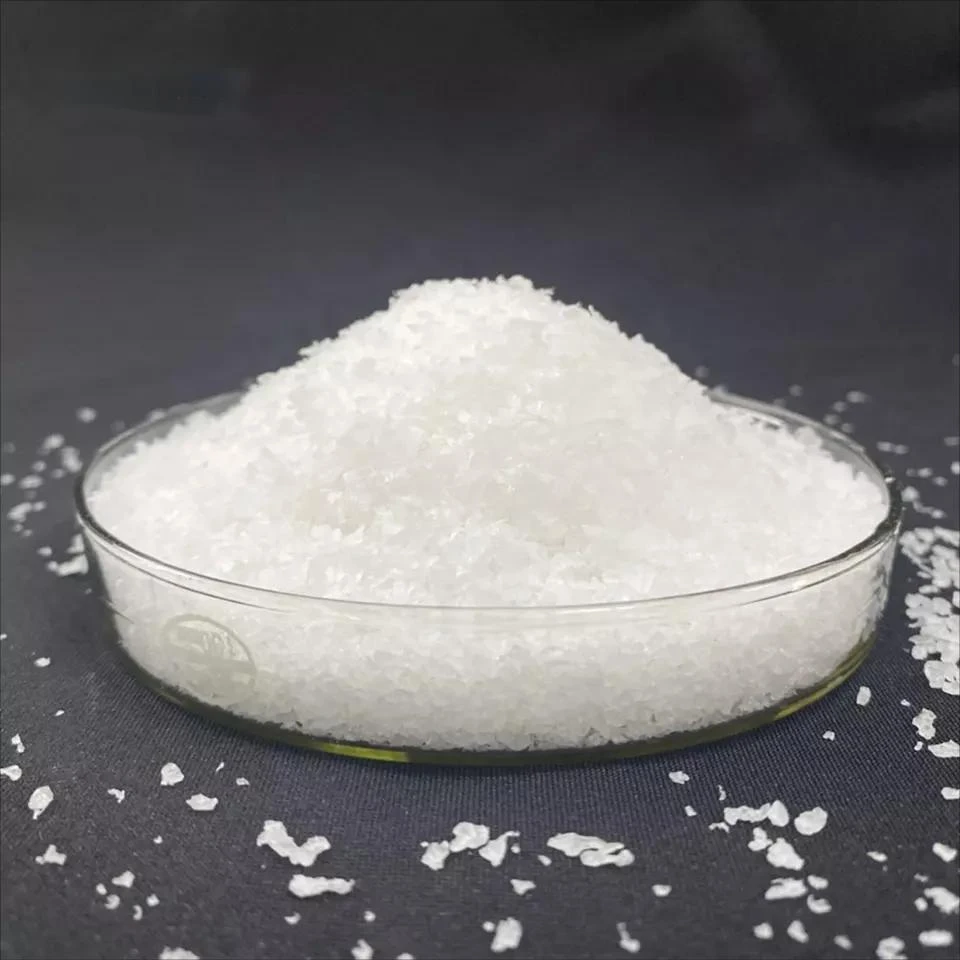

hpmc manufacturing plant

Challenges in HPMC Manufacturing

Despite the robust market and advanced technology, HPMC manufacturing plants face several challenges. The fluctuation of raw material prices can significantly impact production costs. Additionally, compliance with stringent regulatory requirements across different countries can complicate the manufacturing process.

Sustainability has also emerged as a critical concern. As environmental regulations tighten, manufacturers are under pressure to adopt greener practices. This may involve sourcing sustainable raw materials, reducing waste, and minimizing energy consumption during production.

Future Prospects

Looking ahead, the future of HPMC manufacturing plants appears promising, driven by continuous innovation and growing demand in key sectors. As the pharmaceutical industry trends towards personalized medicine, the need for sophisticated excipients such as HPMC is expected to rise. Furthermore, the food industry’s increased focus on clean-label products will likely fuel the demand for high-quality HPMC as a natural thickening and stabilizing agent.

Investments in research and development will play a vital role in enhancing the properties of HPMC, making it more effective for specific applications. Additionally, the integration of Industry 4.0 technologies—such as artificial intelligence and the Internet of Things—could revolutionize manufacturing processes, resulting in higher efficiency and reduced environmental impact.

Conclusion

In conclusion, HPMC manufacturing plants are at the forefront of producing a versatile and essential product for diverse industries. As market demands evolve, these plants must adapt to challenges, invest in sustainable practices, and embrace technological advancements to enhance their operational efficiency. With a commitment to quality and innovation, the HPMC manufacturing sector stands poised for significant growth in the coming years.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025