The Benefits and Applications of HPMC Mortar in Modern Construction

Hydroxypropyl Methylcellulose (HPMC) has emerged as a crucial additive in the formulation of modern mortars, significantly enhancing their performance and versatility. A cellulose ether derived from natural sources, HPMC is widely recognized for its water-retention properties, improved workability, and enhanced adhesion. As construction methods evolve and demand for high-performance materials increases, HPMC mortar stands out as an essential resource in varied applications, ranging from residential buildings to large-scale infrastructure projects.

Key Properties of HPMC Mortar

One of the primary advantages of HPMC in mortar formulations is its exceptional water-retaining capacity. This property allows mortar to remain workable for extended periods, which is especially beneficial in hot weather conditions where evaporation can decrease the effectiveness of traditional mortars. By ensuring that the mortar retains moisture, HPMC promotes better hydration of cement, resulting in increased strength and durability.

Additionally, HPMC contributes to enhanced adhesive properties. When used in tile adhesives or thin-layer mortars, HPMC creates a stable and strong bond between surfaces, ensuring reliable and long-lasting installations. This characteristic is particularly valuable in projects involving tiles, stones, and other materials that require a robust adhesive layer to withstand external stresses and environmental conditions.

Versatility in Applications

HPMC mortar can be applied in various construction scenarios. In residential projects, it is commonly used in tile setting and plastering applications. The improved workability and extended open time provided by HPMC allow for larger installation areas, reducing the time required for completion and increasing efficiency on-site.

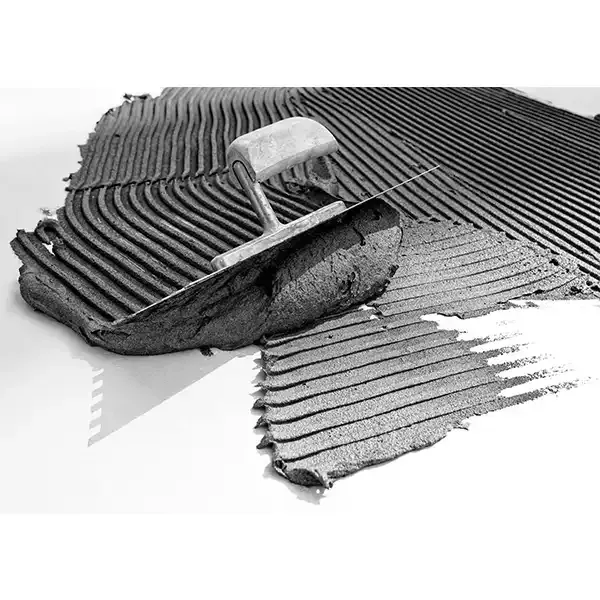

hpmc mortar

In commercial and industrial projects, HPMC mortar is often utilized in the construction of facades and flooring systems. In these contexts, the mortar’s superior adhesion and durability are crucial for bearing heavy loads and tackling environmental challenges.

Furthermore, HPMC mortar is becoming increasingly popular in prefabricated construction. The ability to maintain workability over time translates into seamless joints and robust assemblies in modular buildings, promoting both structural integrity and aesthetic appeal.

Environmental Considerations

In today's construction landscape, sustainability is of paramount importance. HPMC is derived from renewable resources and is biodegradable, making it a more environmentally friendly option compared to many synthetic additives. The efficient use of water in mortar formulations using HPMC can contribute to reducing overall water consumption in construction projects. As awareness of ecological impacts continues to grow, more builders are turning to HPMC mortars to align with sustainable practices.

Conclusion

The integration of HPMC into mortar formulations represents a significant advancement in construction materials technology. With its remarkable properties—enhanced water retention, improved adhesion, and versatility across applications—HPMC mortar is well-suited to meet the demands of modern construction. As the industry moves toward more sustainable practices, the use of HPMC aligns with a future where functionality, durability, and environmental responsibility go hand in hand. As builders and contractors increasingly recognize the advantages of HPMC mortar, it is poised to become a standard in achieving high-quality finishes and reliable structures across a range of applications.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025