Feb . 16, 2025 00:35

Back to list

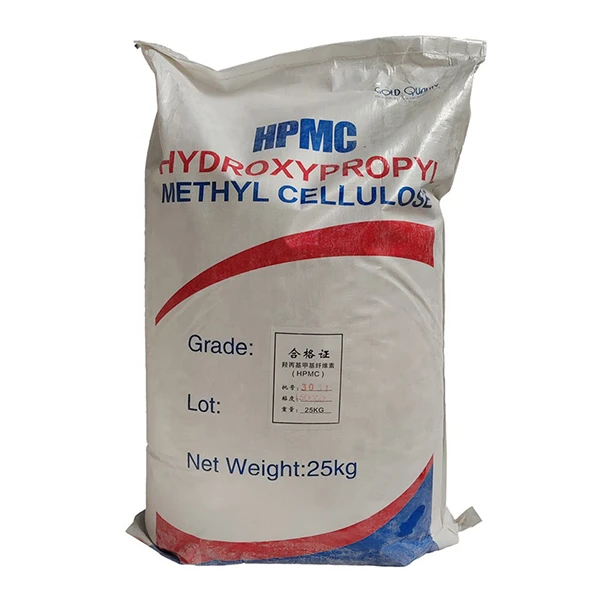

Chemical Chemicals Raw Materials Mhec Manufacturer Good Quality Sales MHEC Cellulose Coating

Revolutionizing the Construction Industry The Impact of Additives for Cement

Authoritativeness in the field is often exhibited by leading companies and industry stakeholders that drive innovation through research and development. Innovations in additive technology underscore the importance of adaptable yet standardized solutions that can meet global construction demands. Companies specializing in additives have consistently pushed the boundaries to address environmental concerns, developing eco-friendly solutions that reduce the carbon footprint associated with traditional cement production. This synthesis not only furthers sustainability but also reflects a commitment to advancing industry standards. Trustworthiness, the cornerstone of any technological advancement, particularly in construction, is reinforced through meticulous testing and adherence to rigorous standards. Regulatory bodies and industry leaders encourage comprehensive assessments to ensure that additives deliver on their promises without unforeseen repercussions. Credible manufacturers provide detailed documentation demonstrating the effectiveness and safety of their products, fostering confidence among engineers and builders. Independent third-party studies often validate suppliers' claims, further contributing to the wide adoption of these technologies in public and private construction ventures. The impact of cement additives extends beyond the immediate improvements to workability or durability. On a broader scale, they contribute to the construction industry's sustainability goals. By improving the efficiency of cement production and the functional longevity of concrete structures, these additives play a vital role in reducing material waste and lowering energy consumption over the lifespan of a project. Consequently, they not only offer economic benefits by optimizing resource use but also adhere to global environmental policies, making them indispensable in modern construction. In conclusion, the evolution of cement additives represents a significant stride in building technology, bridged by the pillars of Experience, Expertise, Authoritativeness, and Trustworthiness. As the construction industry progresses toward more sustainable and resilient architectures, the strategic incorporation of these compounds is paramount for meeting the diverse challenges of tomorrow’s infrastructure needs. Stakeholders at every level—engineers, contractors, policymakers, and suppliers—must recognize and harness the full potential of cement additives to ensure continued growth and innovation in the industry.

Authoritativeness in the field is often exhibited by leading companies and industry stakeholders that drive innovation through research and development. Innovations in additive technology underscore the importance of adaptable yet standardized solutions that can meet global construction demands. Companies specializing in additives have consistently pushed the boundaries to address environmental concerns, developing eco-friendly solutions that reduce the carbon footprint associated with traditional cement production. This synthesis not only furthers sustainability but also reflects a commitment to advancing industry standards. Trustworthiness, the cornerstone of any technological advancement, particularly in construction, is reinforced through meticulous testing and adherence to rigorous standards. Regulatory bodies and industry leaders encourage comprehensive assessments to ensure that additives deliver on their promises without unforeseen repercussions. Credible manufacturers provide detailed documentation demonstrating the effectiveness and safety of their products, fostering confidence among engineers and builders. Independent third-party studies often validate suppliers' claims, further contributing to the wide adoption of these technologies in public and private construction ventures. The impact of cement additives extends beyond the immediate improvements to workability or durability. On a broader scale, they contribute to the construction industry's sustainability goals. By improving the efficiency of cement production and the functional longevity of concrete structures, these additives play a vital role in reducing material waste and lowering energy consumption over the lifespan of a project. Consequently, they not only offer economic benefits by optimizing resource use but also adhere to global environmental policies, making them indispensable in modern construction. In conclusion, the evolution of cement additives represents a significant stride in building technology, bridged by the pillars of Experience, Expertise, Authoritativeness, and Trustworthiness. As the construction industry progresses toward more sustainable and resilient architectures, the strategic incorporation of these compounds is paramount for meeting the diverse challenges of tomorrow’s infrastructure needs. Stakeholders at every level—engineers, contractors, policymakers, and suppliers—must recognize and harness the full potential of cement additives to ensure continued growth and innovation in the industry.

Next:

Latest news

-

The Versatility of Industrial Additives: Mhec, Hpmc, And Wall Putty SolutionsNewsMar.28,2025

-

The Importance of HPMC in Modern IndustriesNewsMar.28,2025

-

Partnering with Reliable Manufacturers for Optimal ResultsNewsMar.28,2025

-

Enhancing Construction Performance with Redispersible Polymer PowdersNewsMar.28,2025

-

Enhancing Construction and Household Products with Advanced AdditivesNewsMar.28,2025

-

Building Strong Foundations with Key Construction MaterialsNewsMar.28,2025