mhec。

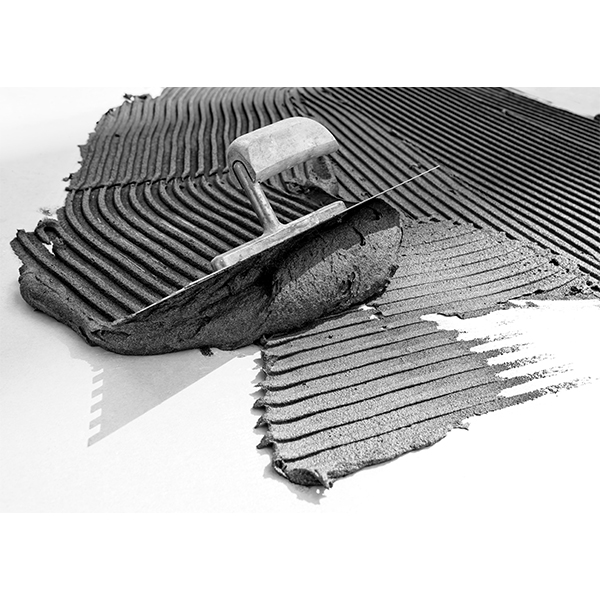

In conclusion, Methyl Hydroxyethyl Cellulose (MHEC) is a valuable additive that can greatly enhance the workability and water retention of cement. By improving workability, MHEC makes it easier for workers to handle and shape the cement, resulting in a more uniform and consistent mixture. Additionally, MHEC enhances water retention, ensuring that the cement remains hydrated for longer periods of time, leading to improved strength and durability. Furthermore, MHEC helps to prevent segregation and bleeding, resulting in a more stable and homogeneous mixture. Lastly, MHEC is compatible with other additives, allowing for greater flexibility in cement formulation. Overall, the use of MHEC in cement offers numerous benefits and is a valuable tool for achieving high-quality and durable construction projects.

chemicals for making cement. It is added to the raw mix before it enters the kiln, where it undergoes high-temperature processing. Calcium sulfate helps to regulate the rate at which tricalcium aluminate reacts with water, preventing premature hardening and improving the strength of the cement.

chemicals for making cement. It is added to the raw mix before it enters the kiln, where it undergoes high-temperature processing. Calcium sulfate helps to regulate the rate at which tricalcium aluminate reacts with water, preventing premature hardening and improving the strength of the cement.

This section provides geographical or regional level reach or their sales network presence for each of company’s considered for profiling.

Methyl Hydroxyethyl Cellulose (MHEC) plays a crucial role in a myriad of applications, from enhancing the performance of construction materials to improving the efficacy and aesthetics of pharmaceuticals and personal care products. Its versatility, coupled with its favorable rheological properties, makes it an indispensable ingredient in numerous industrial formulations.

In general, the gel temperature of HPMC is around 60℃-75℃ depending on its group content and different production technique. Due to the characteristics of MHEC group, it has a higher gel temperature, usually > 80℃. Therefore its stability under high temperature is better that HPMC. In practical construction, in the hot construction environment in summer, the water holding capacity of MHEC with the same viscosity and dosage is better than that of HPMC. Especially in the Southeast Asian countries and India, mortar will sometimes be constructed at high temperature. Cellulose ether with low gel temperature will lose its thickening and water retention at high temperature, thereby accelerating the hardening of mortar, and affects the construction.

Rheology Control: MHEC provides excellent rheology control, allowing for the adjustment of viscosity, flow properties, and texture in formulations. It enables precise control over product performance and application characteristics.