هیدروکسیپروپیل متیل سلولز و کاربردهای آن در صنعت و علم

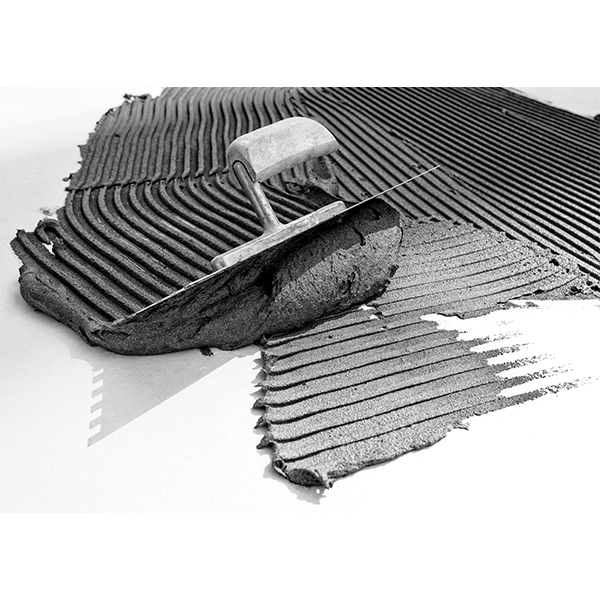

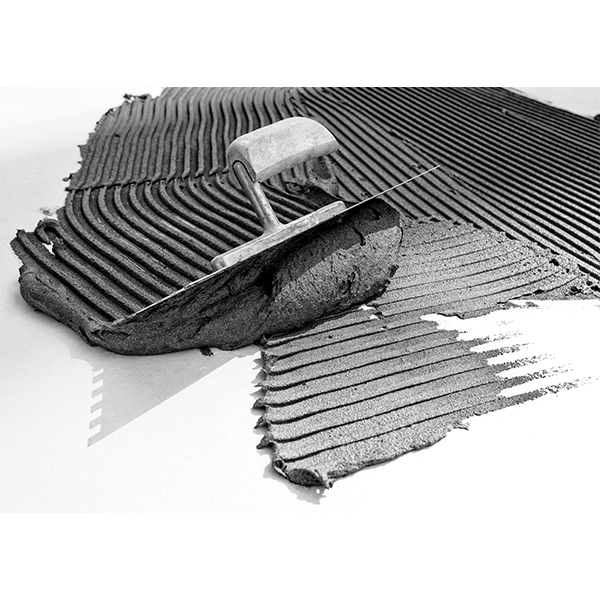

By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product

By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product hpmc for construct grade.

hpmc for construct grade.

It functions as a gelling, thickening, and stabilizing agent, contributing to the texture and consistency of various products, including ice cream, yogurt, and bakery items It functions as a gelling, thickening, and stabilizing agent, contributing to the texture and consistency of various products, including ice cream, yogurt, and bakery items

It functions as a gelling, thickening, and stabilizing agent, contributing to the texture and consistency of various products, including ice cream, yogurt, and bakery items It functions as a gelling, thickening, and stabilizing agent, contributing to the texture and consistency of various products, including ice cream, yogurt, and bakery items mecellose hpmc. Its non-ionic nature ensures compatibility with other food ingredients, making it a popular choice for formulators.

mecellose hpmc. Its non-ionic nature ensures compatibility with other food ingredients, making it a popular choice for formulators.

The global construction industry is expanding due to factors such as urbanization, infrastructure expansion, and the increased focus on sustainable building techniques. These factors are driving the MHEC market. With regulations prioritizing more ecologically friendly building materials, there will be a sharp increase in demand for MHEC, which is made from renewable cellulose sources.

Furthermore, MHEC enhances the water resistance of cement. When MHEC is added to the mix, it forms a protective barrier that prevents water from penetrating the cement structure. This is particularly important in applications where the cement will be exposed to moisture, such as in swimming pools or basements. The improved water resistance provided by MHEC ensures that the cement remains strong and intact, even in wet conditions.

Application of hydroxypropyl methyl cellulose (HPMC) in building mortar and plastering mortar

High water retention can make the cement fully hydrated, significantly increase the bond strength, and appropriately improve the tensile elongation and shear strength, greatly improving the construction effect and working efficiency.

Application of hydroxypropyl methyl cellulose (HPMC) in water-resistant putty powder

The cellulose ether in the putty powder is mainly used for water retention, bonding and lubrication to avoid cracks and dehydration caused by rapid water loss. At the same time, it enhances the adhesion of the putty, reduces the sagging phenomenon in the construction, and makes the construction more smooth.

Application and function of hydroxypropyl methyl cellulose (HPMC) in plaster series

In gypsum series products, cellulose ether mainly plays the role of water retention, increasing lubrication, and has a certain retarding effect, which solves the problems of bulging and failure to reach the initial strength in the construction process, and can prolong the working time.

Application of hydroxypropyl methyl cellulose (HPMC) in interfacial agent

It is mainly used as a thickener, which can improve the tensile strength and shear strength, improve the surface coating, and enhance the adhesion and bonding strength.

Application and function of hydroxypropyl methyl cellulose (HPMC) in exterior wall thermal insulation mortar

Cellulose ether plays a key role in bonding and increasing strength in this material, which is that sand will be easier to be coated, improve work efficiency, and have anti vertical flow effect at the same time. Higher water retention performance can prolong the working time of mortar, improve shrinkage and cracking resistance, improve surface quality, and improve bonding strength.

Application of hydroxypropyl methyl cellulose (HPMC) in tile binder

The high water retention can significantly improve the bonding strength of ceramic tiles and bases without soaking or wetting them in advance. The slurry can have long construction cycle, fine, uniform, convenient construction, and good moisture resistance at the same time.

Application and function of hydroxypropyl methyl cellulose (HPMC) in joint sealant and gutter sealant

The addition of cellulose ether makes it have good edge adhesion, low shrinkage and high wear resistance, which protects the base material from mechanical damage and avoids the impact of penetration on the whole building.

Application of hydroxypropyl methyl cellulose (HPMC) in self leveling materials

The stable adhesion of cellulose ether ensures good fluidity and self leveling ability. The water retention rate is controlled so that it can solidify rapidly and reduce cracking and shrinkage.

Its fast-drying characteristic is another bonus, allowing for quick project completion and minimal downtime Its fast-drying characteristic is another bonus, allowing for quick project completion and minimal downtime

Its fast-drying characteristic is another bonus, allowing for quick project completion and minimal downtime Its fast-drying characteristic is another bonus, allowing for quick project completion and minimal downtime cellulose paint . It also offers superior UV protection, which helps maintain the original color and finish for longer periods.

cellulose paint . It also offers superior UV protection, which helps maintain the original color and finish for longer periods.