Create a title inspired by youngcel that captures a similar essence in under 15 words.

Another advantage of using MHEC in construction materials is its compatibility with other additives. MHEC can be easily combined with other chemicals and additives, such as cement, lime, or polymers, without affecting its performance. This versatility allows for greater flexibility in formulation, enabling manufacturers to tailor the properties of the material to meet specific requirements. Whether it is improving adhesion, increasing strength, or enhancing flexibility, MHEC can be used in conjunction with other additives to achieve the desired results.

In addition to improving workability, MHEC also enhances the water retention properties of cement. Water retention is crucial in cement applications as it ensures that the mixture remains hydrated for an extended period of time. This is particularly important in hot and dry climates where evaporation can occur rapidly. By adding MHEC to cement, the water is effectively trapped within the mixture, preventing it from evaporating too quickly. This allows for better hydration of the cement, resulting in improved strength and durability of the final product.

Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process

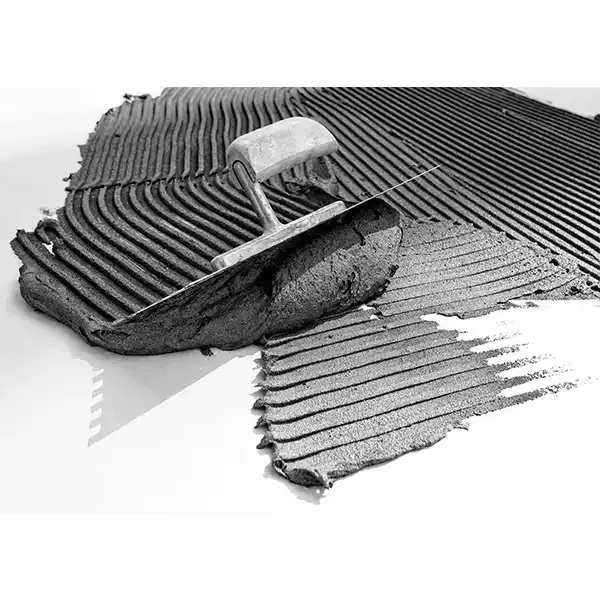

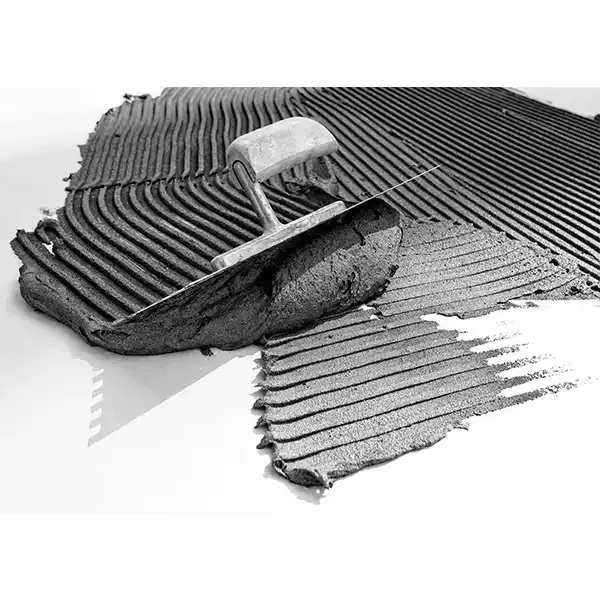

Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process Many RDP formulations are low in volatile organic compounds (VOCs), contributing to better air quality during and after the installation process rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.

rdp for ceramic tile adhesive. This aligns with the increasing demand for sustainable building materials and practices.Thermal stability of HPMC and MHEC is affected by their gel temperature. In general, the gel temperature of HPMC is around 60℃-75℃ depending on its group content and different production technique. Due to the characteristics of MHEC group, it has a higher gel temperature, usually > 80℃. Therefore its stability under high temperature is better that HPMC. On the other hand, because there are more hydrophilic groups in the structure of MHEC, it has better hydrophilicity. The water retention rate of MHEC in mortar is a little higher than HPMC at the same dosage of products with the same viscosity.