Utilisation de l'hydroxyéthylméthylcellulose dans les savons liquides pour une texture améliorée

The setting time of concrete is mainly related to the setting time of cement, and the aggregate has little effect, so the setting time of mortar can be used instead of studying the effect of HP cellulose on the setting time of underwater non dispersible concrete mixture. Since the setting time of mortar is affected by water cement ratio and cement sand ratio, in order to evaluate the effect of HP cellulose on the setting time of mortar, it is necessary to fix the water cement ratio and cement sand ratio of mortar.

Mixing is then performed to ensure that the HPMC is evenly distributed throughout the formulation Mixing is then performed to ensure that the HPMC is evenly distributed throughout the formulation

Mixing is then performed to ensure that the HPMC is evenly distributed throughout the formulation Mixing is then performed to ensure that the HPMC is evenly distributed throughout the formulation grade hpmc. Finally, granulation is carried out to convert the powder mixture into larger, more uniform granules, which are easier to handle and process.

grade hpmc. Finally, granulation is carried out to convert the powder mixture into larger, more uniform granules, which are easier to handle and process. Moreover, they offer better formaldehyde emissions control compared to traditional urea-formaldehyde adhesives, contributing to healthier indoor air quality Moreover, they offer better formaldehyde emissions control compared to traditional urea-formaldehyde adhesives, contributing to healthier indoor air quality

Moreover, they offer better formaldehyde emissions control compared to traditional urea-formaldehyde adhesives, contributing to healthier indoor air quality Moreover, they offer better formaldehyde emissions control compared to traditional urea-formaldehyde adhesives, contributing to healthier indoor air quality cellulose adhesive .

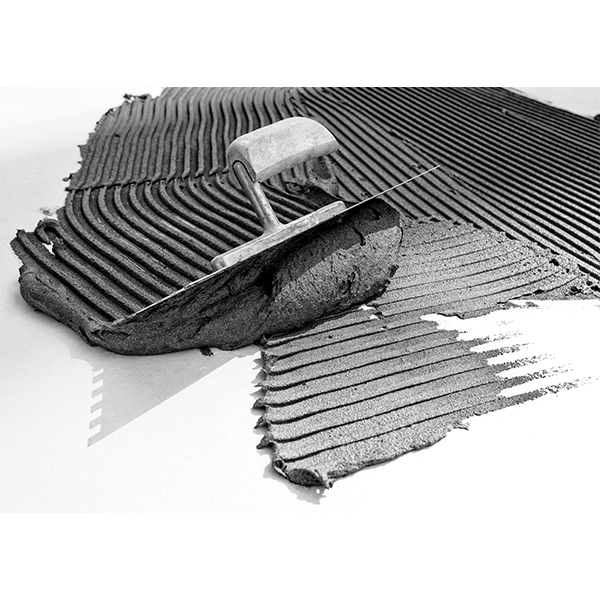

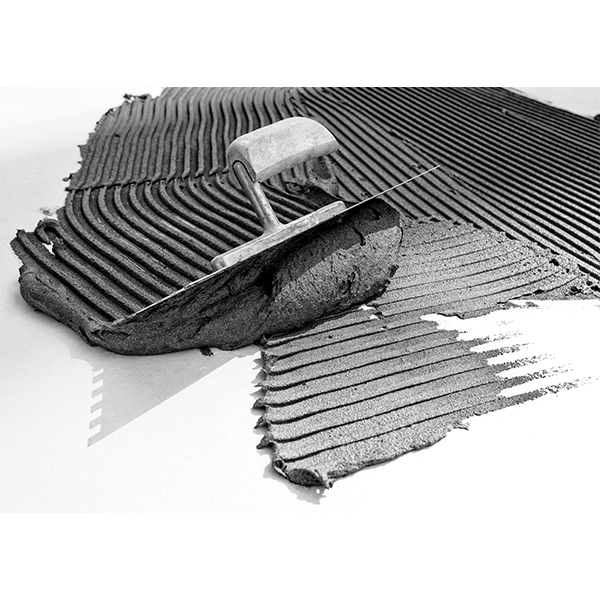

cellulose adhesive . By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product

By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product By incorporating HPMC into cementitious materials, such as tile adhesives and self-leveling compounds, construction professionals can improve adhesion strength and durability, resulting in a more reliable and long-lasting finished product hpmc for construct grade.

hpmc for construct grade.