ethyl hydroxi ethyl cellulos

It also enhances resource optimization, as managers can monitor equipment usage and workforce allocation from a centralized platform It also enhances resource optimization, as managers can monitor equipment usage and workforce allocation from a centralized platform

It also enhances resource optimization, as managers can monitor equipment usage and workforce allocation from a centralized platform It also enhances resource optimization, as managers can monitor equipment usage and workforce allocation from a centralized platform construction rdp .

construction rdp .

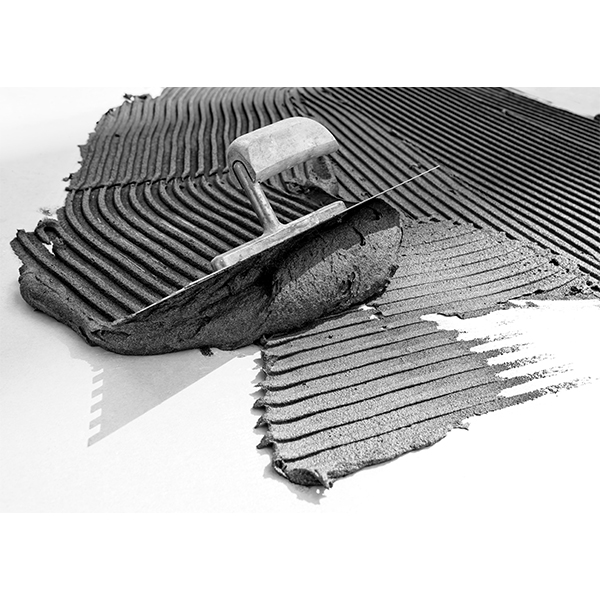

In the construction industry, it is used as a binder in cementitious products, such as adhesives and coatings, to improve workability and durability In the construction industry, it is used as a binder in cementitious products, such as adhesives and coatings, to improve workability and durability

In the construction industry, it is used as a binder in cementitious products, such as adhesives and coatings, to improve workability and durability In the construction industry, it is used as a binder in cementitious products, such as adhesives and coatings, to improve workability and durability cellulose ether.

cellulose ether.

The production process of MHEC powder involves several sequential stages. It commences with the extraction of cellulose from natural sources like wood pulp or cotton. Subsequently, the extracted cellulose undergoes alkalization. The ensuing step encompasses etherification via sodium mono chloroacetate, culminating in the production of MHEC. This resultant substance is then subjected to purification, drying, and milling, ultimately yielding the final MHEC product.

chemicals for making cement. It is added to the raw mix before it enters the kiln, where it undergoes high-temperature processing. Calcium sulfate helps to regulate the rate at which tricalcium aluminate reacts with water, preventing premature hardening and improving the strength of the cement.

chemicals for making cement. It is added to the raw mix before it enters the kiln, where it undergoes high-temperature processing. Calcium sulfate helps to regulate the rate at which tricalcium aluminate reacts with water, preventing premature hardening and improving the strength of the cement.