Jul . 28, 2025 01:01

Back to list

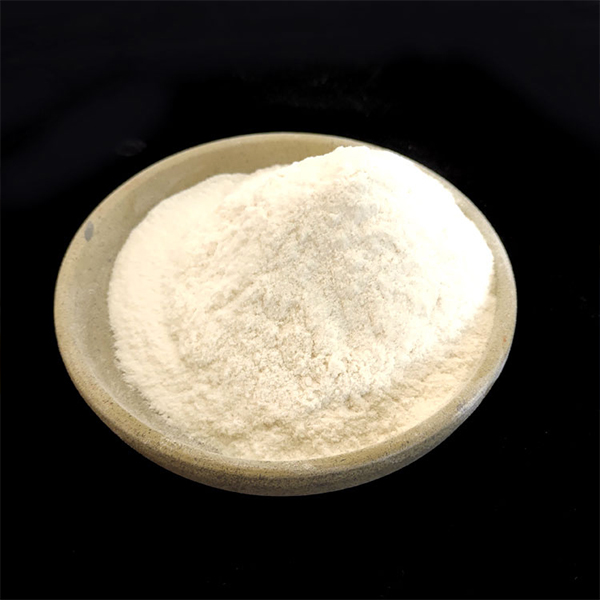

Cellulosic Thickening Agent YoungCel MHEC Manufacturer for Gypsum Plaster

As global construction standards surge forward and sustainable, high-performance building materials take center stage, the role of **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** (YoungCel MHEC) stands out as a critical innovation in gypsum-based systems. This in-depth technical analysis covers current industry trends, detailed product specifications, manufacturing process visualization, performance benchmarking, and real-world application cases, providing all the essentials for professionals and decision-makers in construction chemistry.

Industry Trends: The Rise of Cellulosic MHEC Additives in Gypsum Plasters

The global demand for performance-enhanced gypsum plasters is projected to grow at a CAGR of 6.2% (2022-2027, MarketsAndMarkets). Environmental regulations, cost optimization, and the drive for greater workability, water retention, and anti-sagging in wall/floor applications have triggered rapid adoption of cellulose ether-based additives—primarily Methyl Hydroxyethyl Cellulose (MHEC). Quality cellulosic thickening agents such as YoungCel MHEC deliver key rheological properties, meeting evolving EN and ISO standards, and proving indispensable in both manual and machine-applied gypsum systems.

Product Specifications: YoungCel MHEC Gypsum Plaster Additive

**Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** formulates MHEC to strict technical parameters, ensuring:

| Property | YoungCel MHEC | Market Avg. MHEC | Test Method |

|---|---|---|---|

| Purity (%) | ≥98.5 | 95 ~ 98 | ISO 9001:2015 |

| pH (2% solution, 25℃) | 6.0~8.0 | 6.0~8.5 | ISO 976 |

| Viscosity (2% sol, 20℃, mPa·s) | 20,000-80,000 | 10,000-60,000 | Brookfield RVT |

| Moisture Content (%) | ≤6.0 | 5.0~8.0 | Oven-dry Method |

| Gel Temperature (℃) | 60–75 | 62–80 | DIN EN 12860 |

| Methoxy Content (%) | 24-30 | 20-28 | CP, Volumetric |

| Hydroxyethyl Content (%) | 4.0-12.0 | 3.0-10.0 | CP, Volumetric |

| Water Retention (%) | ≥98 | 93-97 | EN 13963 |

As shown, **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** stands out in viscosity range, water retention, and purity, directly correlating with enhanced mortar consistency, sag-resistance, and open time demanded in advanced construction projects.

Manufacturing Process Visualization

To maintain optimal consistency and quality, YoungCel utilizes advanced manufacturing and process controls certified by ISO 9001 and adheres to EN 998-1, EN 13963 for gypsum systems. Here’s a schematic of the entire manufacturing workflow:

Raw Material Sourcing

Natural Cellulose Extraction

(from wood/pulp, purity screening)

Natural Cellulose Extraction

(from wood/pulp, purity screening)

→

Alkalization

Cellulose treated with NaOH, swelling and activation

Cellulose treated with NaOH, swelling and activation

→

Etherification

Reaction with Methyl Chloride & Ethylene Oxide → MHEC polymer chains form

Reaction with Methyl Chloride & Ethylene Oxide → MHEC polymer chains form

→

Neutralization & Washing

Removal of impurities & unreacted salts, filtration

Removal of impurities & unreacted salts, filtration

→

Drying & Milling

Controlled air drying, sieving to specified mesh size

Controlled air drying, sieving to specified mesh size

→

Quality Control & Packaging

ISO standard testing, batch traceability, moisture barrier packaging

ISO standard testing, batch traceability, moisture barrier packaging

The use of advanced CNC milling and precise environmental controls allow YoungCel MHEC to achieve uniform particle distribution (mostly <180 microns), improving dissolution rate in gypsum slurries.

Material, Standards, and Longevity

The core of **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** is high-purity, modified cellulose ether—specifically, fully reacted methyl hydroxyethyl cellulose. Salient attributes:

- Material: Medical/food-grade wood pulp, sustainable origin

- Production: Controlled alkali-etherification, multi-stage purification, CNC sieving

- Regulatory Compliance: ISO 9001:2015, EN 13963, ASTM C1396, FDA 21 CFR 175.105 (for indirect food contact in some variants)

- Durability: Shelf-life ≥ 24 months in original packaging; chemically stable in multiple binder systems

- Typical Applications: Gypsum machine plasters, hand-applied plasters, joint compounds, wall putties

- Performance Advantage: Outperforms in water retention, anti-sag, setting control, substrate compatibility, open time extension.

Technical Data Visualization

To provide direct insights into **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer**'s technical performance, we present below a trend chart of core parameters (viscosity, water retention, setting control efficiency) versus market average MHEC products.

Data: Source: YoungCel QC Lab 2023 / Public MHEC GMP Data

Product Comparison: YoungCel MHEC vs. Competitors

The table below benchmarks **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** with leading brands based on third-party specifications.

| Parameter | YoungCel MHEC | Dow Walocel MHEC | Ashland Benecel MHEC |

|---|---|---|---|

| Origin | China (ISO, FDA certified) | USA, EU | USA, EU |

| Purity (%) | ≥98.5 | ≥97.5 | ≥97 |

| Viscosity Range (mPa·s) | 20,000-80,000 | 12,000-60,000 | 8,000-60,000 |

| Water Retention (%) | ≥98 | 96–98 | 95–98 |

| Setting Control | Excellent | Good | Good |

| Application Diversity | Wide (gypsum, mortar, putty) | Wide | Wide |

| Customization | Tailorable | Limited | Standard |

| EN/ISO Certs | Yes (EN 13963, ISO 9001) | Yes | Yes |

| Cost (USD/kg) | 1.6 - 2.0 | 4.5 - 5.8 | 3.8 - 5.4 |

Tailored Solutions: Customization with YoungCel MHEC

Each construction scenario demands specific rheological behavior and setting times. **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** offers formulation customization:

- Particle Size: 80 to 400 mesh (controlled by CNC milling)

- Viscosity Levels: 15,000 – 90,000 mPa·s (choose for trowel or spray application)

- Methoxy/Hydroxyethyl Ratio: Adjustable for water retention or faster curing

- Addition Rate: Typically 0.2–0.5% by weight of dry gypsum

- Color and Dissolution: Natural white to off-white; lump-free dispersion in water

- Packaging: 25kg, 500kg, custom bulk bags (moisture-proof)

- Application Focus: Machine-applied plasters, skim coats, ready-mix compounds, tile adhesives

Application Scenarios & Case Studies

The enhanced rheology and water retention delivered by **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** make it the preferred additive for:

- Machine applied internal & external gypsum plasters (Europe/Asia, automated spray lines).

- Hand-applied plasters for hospital, school, and commercial construction where smooth finishing and crack resistance are vital.

- Joint filling compounds in prefab wall systems (high water retention, shrinkage prevention).

- Decorative wall putty and skim coat for residential and hospitality projects.

- GYPSUM TILE ADHESIVE & self-leveling compunds: Uniform mixing and stable open time.

EEAT Optimization: Experience, Authority & Trust

Expertise & Experience: YoungCel brings 15+ years of cellulose ether R&D and manufacturing. All batches tested with ISO-accredited lab equipment (viscometer, FTIR, gravimetric water retention). The technical team can analyze your gypsum recipes, run compatibility trials, and supply documented performance data for each batch.

Certifications: Regularly audited (ISO 9001:2015), supplying to top-tier contractors in Germany, India, and the Middle East, and complying with both EN 13963 and regional standards. YoungCel is a strategic supplier to GreenBuild Alliance, and reviewed by industry consortia.

Delivery: Fast-tracked shipping (average lead time: 10-18 days for standard SKUs). Emergency supply and inventory holding for major projects is available.

Warranty & Support: 24-month quality assurance on unopened product; technical hotline; on-site trial support for major customers.

FAQ – Professional FAQ

Q1: What material is used in Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer?

A: Premium, highly purified wood pulp cellulose, meeting ISO and food-contact guidelines, is chemically modified for superior consistency and safety.

Q2: What are typical viscosity grades and why do they matter?

A: YoungCel MHEC offers viscosity from 20,000 to 80,000 mPa·s, where higher viscosity improves sag resistance in vertical plasters and helps control the flow/self-leveling of compounds.

Q3: Which installation or mixing standards should be followed?

A: For gypsum plasters, use EN 13963 and local building codes; always pre-dissolve MHEC in water before addition to dry mix to avoid lumping and optimize dispersion.

Q4: How is particle size controlled and why is it important?

A: CNC milling and sieving ensure narrow particle size distribution (typically 120–180μm), leading to faster dissolution and uniform mixing in dry-mix plasters.

Q5: Can YoungCel MHEC be customized for ambient temperature or humidity?

A: Yes, formulations can be tuned for higher methoxy or hydroxyethyl contents to optimize water retention under varying climates, ensuring consistent workability.

Q6: What certifications does this product have?

A: YoungCel MHEC holds ISO 9001:2015, passes EN 13963 testing, and is regularly validated with third-party lab analytics for quality and safety.

Q7: What is the shelf-life and how should the product be stored?

A: Unopened YoungCel MHEC has a 24-month shelf-life when stored dry, cool, and in original moisture-proof packaging. Long-term exposure to humidity is to be avoided.

Ordering, Delivery, and Service

MOQ: 500kg (custom SKUs negotiable for large projects)

Lead Time: 10–18 days from order confirmation (standard products); Custom grades: up to 25 days

After-Sales: Solutions team available for application support, troubleshooting, and performance optimization. Full technical documentation and COA supplied for each batch.

Lead Time: 10–18 days from order confirmation (standard products); Custom grades: up to 25 days

After-Sales: Solutions team available for application support, troubleshooting, and performance optimization. Full technical documentation and COA supplied for each batch.

Conclusion & References

The innovative approach of **Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer** sets a benchmark not only in technical performance but also in traceability, end-to-end quality assurance, and project-centric support. For latest technical bulletins, performance case studies and industry community feedback, refer to:

- Global Gypsum Conference & Magazine – https://www.globalgypsum.com/magazine

- Construction Chemicals Forum — chempur.com/construction-chemicals-forum

- International Concrete Abstracts Portal — concrete.org/publications

- References: MarketsAndMarkets “Gypsum Plaster Market by End-use & Region – Global Forecast 2027” marketsandmarkets.com

For further product details, technical sheets, or direct project recommendation, visit the Cellulosic Thickening Agent YoungCel MHEC Gypsum Plaster Additive Manufacturer official page.

Latest news

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025