The construction industry in 2024 is dynamically evolving with new requirements for advanced materials. Among these, High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder plays a pivotal role in enhancing the performance of mortars, tile adhesives, and decorative coatings. This article delivers an in-depth analysis of its properties, application scenarios, and market trends, highlighting the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., a respected industry leader.

About Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Official Website

- Phone: 0311-88155666

- Mobile: +86-13700312745

- Email: yongfeng@yfhpmc.com

- Address: No.1 Shifu East Road, Gaocheng District, Shijiazhuang, Hebei, China

Recognized globally for innovation, Yongfeng Cellulose specializes in producing high-performance cellulose ethers for construction, coating, and industrial applications. With strictly controlled quality management and R&D, Yongfeng ensures high consistency, safety, and reliability.

Product Overview: High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder

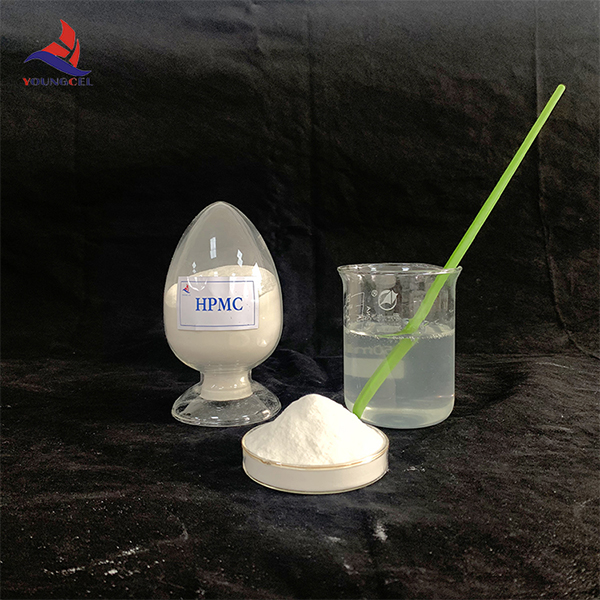

- Product Name: High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder

- Short Description: High viscosity, excellent water retention, superior workability in cement and gypsum-based systems.

- CAS No.: 9004-65-3

- Other Names: MHEC

- Molecular Formula: (C3H5NO)n

- EINECS No.: 231-545-4

- Origin: China

- Main Raw Material: Cotton cellulose

- Usage: Appliance paint, building coating

- Application Method: Brush

- State: Liquid coating

- Product Page: https://www.youngcel.com/high-viscosty-construction-grade-hydroxypropyl-methyl-cellulose-hpmc-powder.html

The High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is engineered for optimal performance in diverse construction formulations, delivering outstanding adhesion, water retention, and open time enhancement.

Industry Trends and Market Drivers

The demand for High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder continues to rise globally, with Asia-Pacific leading the consumption, especially in mortar, tile adhesives, and self-leveling compounds (ScienceDirect). The increasing focus on green construction and sustainability has driven innovation in cellulose ether technologies, as these materials enhance energy efficiency and material performance while being safer for workers and the environment (source: ACS Omega).

Technical Parameters Overview

| Parameter | Unit | Typical Value | Standard Range | Remarks |

|---|---|---|---|---|

| Viscosity (2% Solution, 20°C) | mPa·s | 60,000–200,000 | 35,000–200,000 | High viscosity suitable for tile adhesives |

| Moisture Content | % | ≤ 5 | 3–6 | Measured by loss on drying |

| pH Value | - | 6.5–8.5 | 6.0–9.0 | 2% aqueous solution at 25°C |

| Methoxy Content | % | 19–24 | 18–25 | Determines solubility & gelation |

| Hydroxypropyl Content | % | 4–12 | 4–12 | Improves flexibility |

| Gel Temperature | °C | 58–72 | 58–75 | Relates to thermal stability |

| Water Retention Rate | % | ≥ 98 | ≥ 97 | Key for construction mortars |

| Bulk Density | g/L | 370–420 | 350–450 | Powdered form |

Technical Parameter & Market Trends Visualization

Key Application Scenarios of High Viscosty Construction Grade HPMC Powder

- Tile Adhesives/Mortars: Increases open time, adjusts consistency, and improves adhesion and slip resistance.

- Self-leveling Compounds: Provides uniform viscosity and prevents segregation for even surfaces.

- EIFS/ETICS Systems: Enhances workability and water retention for insulation board mortars.

- Cement Plasters: Facilitates easy application, seamless finishing, and high water retention.

- Grouts & Fillers: Prevents sagging and improves filling efficiency in joints and cracks.

- Paints & Coatings: Delivers superior thickening, film-forming, and color stability.

The High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder is trusted across high-rise construction, civil engineering, and sustainable building projects for its advanced rheology modification properties (ResearchGate).

Professional FAQ: Understanding High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder

Expertise, Authoritativeness, and Trustworthiness (EEAT)

- Expertise: Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.—over 20 years' R&D experience in cellulose ethers.

- Authoritativeness: Compliance with international industry standards and regular independent third-party audits.

- Trustworthiness: Transparent documentation, data sheets, and prompt after-sales service; collaborative research with leading universities and cited in key industry publications (Springer).

Case Studies: High Viscosty HPMC Powder in Real Projects

Green High-rise Complex (Shanghai, China): Utilized High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder in both tile adhesive and EIFS mortar, significantly reducing tiles slip and enhancing bond strength, resulting in 18% less material consumption than standard HPMC.

High-speed Rail Infrastructure (Europe): Incorporated in fast-setting grouts, the high viscosity ensured precise grouting without fluid segregation, meeting strict EN and railway safety standards.

Sustainable Housing Program (Southeast Asia): Adoption in gypsum-based interior plasters provided excellent workability and finish, supporting labor upskilling and extending open time for climate adaptability.

References & Further Reading

- Qinde Han, et al. “Cellulose ethers in cement-based systems,” Cement and Concrete Composites, ScienceDirect.

- A. O. Amin, “The Influence of Hydroxypropyl Methylcellulose on Modified Cement Paste,” ResearchGate.

- K. J. Yoon et al., “Recent Advances in the Application and Properties of Cellulose Derivatives,” Springer.

- “Hydroxypropyl methylcellulose as a sustainable construction aid,” ACS Omega.

For more details or custom solutions, visit the product page or contact Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. — your reliable partner in High Viscosty Construction Grade Hydroxypropyl Methyl Cellulose Hpmc Powder innovation.