Understanding HPMC Grade A Comprehensive Overview

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer that has become pivotal in various industries, particularly in pharmaceuticals, food applications, construction, and cosmetics. As a modified cellulose derivative, HPMC possesses unique properties that make it an essential ingredient in many formulations. One of the key aspects to consider when working with HPMC is its grade, which influences its performance and suitability for particular applications. This article delves into the significance of HPMC grades, their characteristics, and their implications across different sectors.

What is HPMC?

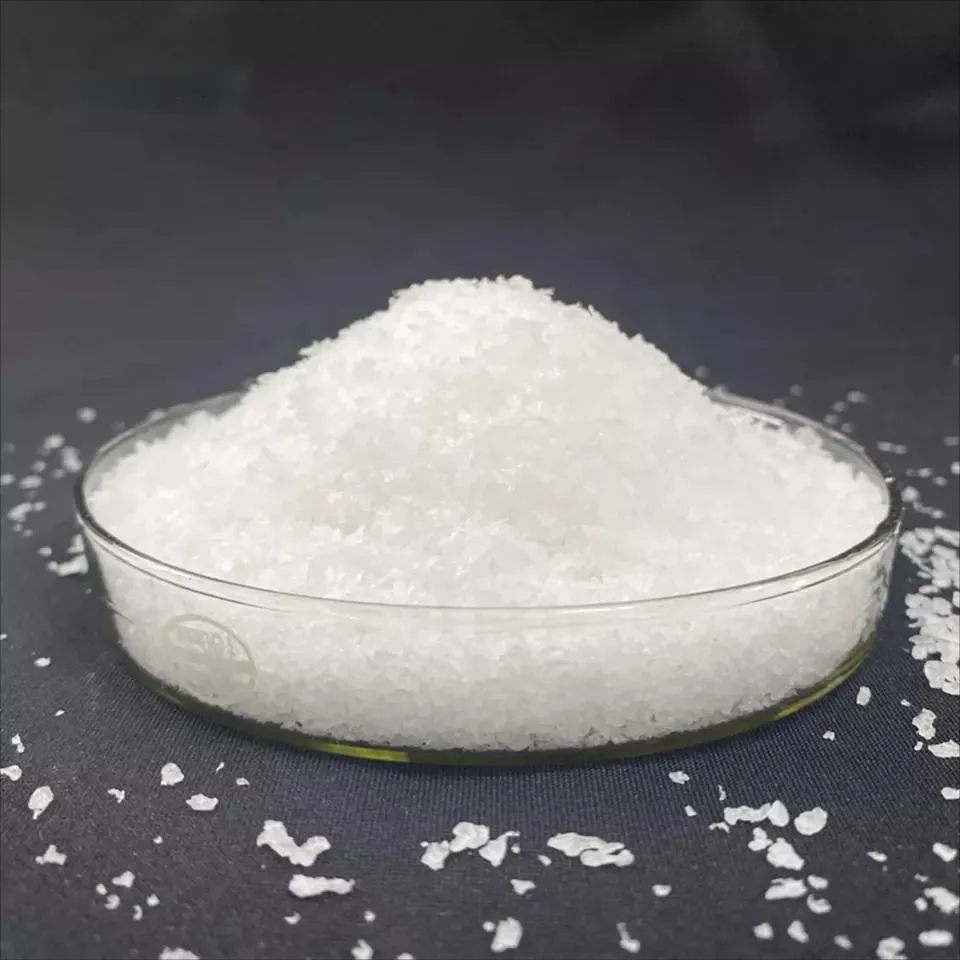

HPMC is a white, odorless powder derived from cellulose, a natural polymer found in the cell walls of plants. The modification of cellulose through etherification transforms it into HPMC, which offers various functional benefits. Its solubility in water and organic solvents, along with its ability to form gels, make HPMC an invaluable ingredient in a range of products.

The Importance of HPMC Grade

HPMC is available in various grades, each defined by specific characteristics such as viscosity, molecular weight, and methoxy/hydroxypropyl content. These parameters are crucial because they determine the behavior of HPMC in different formulations. Different applications require different HPMC grades to achieve the desired consistency, adhesion, and stability.

1. Viscosity The viscosity of HPMC is one of its foremost characteristics. It is usually measured in centipoise (cP) or Millipascal seconds (mPa·s). Higher-viscosity HPMC grades are predominantly used in heavy-duty applications like thickening agents in food products, while lower-viscosity grades are ideal for applications requiring a smoother texture, such as in pharmaceutical formulations.

hpmc grade

2. Methoxy and Hydroxypropyl Content The ratio of methoxy to hydroxypropyl groups in HPMC affects its solubility and gel-forming capacity. High methoxy content offers better film-forming properties, making it ideal for coatings and adhesives. Conversely, higher hydroxypropyl content increases solubility in cold water, thereby enhancing its application in products like sauces and dressings.

3. Food and Pharmaceutical Applications In the food industry, HPMC is often used as a thickener, emulsifier, and stabilizer. Its ability to improve texture and extend shelf life makes it a popular choice among food manufacturers. In pharmaceuticals, HPMC serves as a binder in tablets, a thickening agent in gels, and even as a coating material for controlled-release medication. The specific grade of HPMC used can drastically impact the efficiency and efficacy of a drug delivery system.

4. Construction and Coatings In the construction industry, HPMC is utilized in mortars, putties, and plaster products. Its water retention properties ensure that mixtures remain workable for extended periods, which is crucial for effective application and finishing. Additionally, when used in coatings, HPMC enhances adhesion and provides a uniform finish, making it indispensable in paints and varnishes.

Choosing the Right HPMC Grade

Selecting the ideal grade of HPMC hinges on the intended application. Factors such as required viscosity, solubility, texture, and desired shelf life should be comprehensively assessed. Manufacturers must conduct thorough testing to identify the best-suited grade that meets regulatory standards and performance expectations.

Conclusion

In summary, understanding HPMC grades is essential for those working in industries that utilize this potent polymer. The varying characteristics of different grades can significantly influence the properties of the final product, be it in pharmaceuticals, food processing, construction, or cosmetics. With ongoing research and development in polymer science, the future of HPMC looks promising, leading to innovative applications and formulations that meet the diverse needs of consumers and industries alike. Therefore, it is vital for professionals in these fields to remain informed about the advancements in HPMC technology and its varied grades to fully leverage its potential.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025